Nexturn SA(B) Series 7-Axis High Precision CNC Swiss-Type Automatic Lathes

Click here for Special Offers Buy a Nexturn SA-B Series Swiss Lathe & get a FREE Bar Feeder

The Nexturn SA(B) Series represents a proven line of 7-axis high precision CNC Swiss-type automatic lathes designed for continuous production of small, complex, and tight-tolerance components. Engineered and built in Korea, these machines combine Fanuc or Mitsubishi CNC controls with the highest-quality components — NSK ballscrews, THK linear guideways, FAG bearings and KHK gears — to deliver unmatched rigidity, accuracy, and dependability.

Ideal for industries requiring precision production turning such as medical, aerospace & defense, automotive, electronics, and general small-parts manufacturing, the SA(B) Series provides the stability and accuracy needed for machining high-value parts in demanding production environments. Competing directly with machines from Marubeni Citizen-Cincom, Star, Tornos, Doosan, Hanwha, Mazak, Swiss-Tech, and Swissturn, Nexturn offers a more cost-effective solution without compromising on speed, rigidity, or performance.

Key Features

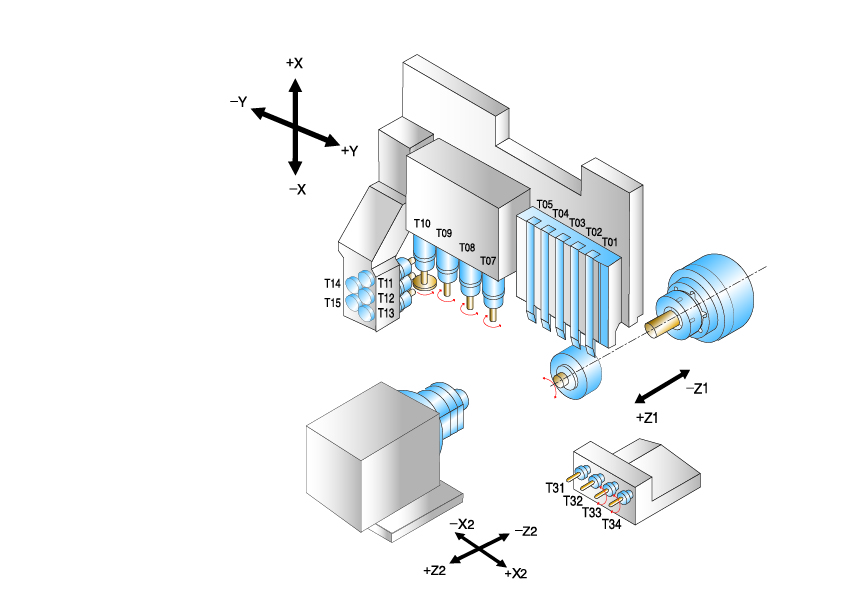

- 7-Axis Simultaneous Control: Z1, X1, Y, Z2, X2, C1, and C2 axes provide full multi-channel machining on both main and sub-spindles.

- Tooling Capacity: Up to 22 total tools (depending on model) including OD turning, Y-axis ID, and live tooling for extensive machining flexibility.

- Bar Capacities:

- SA-12B: 12mm (0.472″)

- SA-20B: 20mm (0.787″)

- SA-32B: 32mm (1.26″)

- Spindle Performance:

- Main Spindle: Up to 10 HP / 10,000 RPM built-in motor for high-speed, high-rigidity cutting.

- Sub-Spindle: Up to 3 HP / 8,000 RPM, enabling simultaneous back-side machining.

- Dual Channel Control Architecture: Powered by either Fanuc 0i-TF Plus or Mitsubishi M80A, offering conversational programming, 3D graphics, Ethernet connectivity, and dual-path synchronization.

- Guide Bushing Options: Full-stroke rotary synchronous guide bushing with dual bearing structure for superior support and accuracy; optional non-guide bushing configurations available.

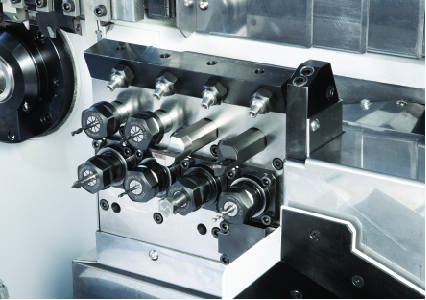

- Live Tooling Power: Up to 1.3 HP / 6,000 RPM cross-drilling units and 1 HP / 5,000 RPM back-end live tooling for milling, drilling, and tapping with ER-16 collet interfaces.

- Chip & Coolant Systems: Optional high-pressure coolant up to 2,000 PSI improves chip evacuation and extends tool life; lift-up style door and efficient enclosure design ensure operator comfort and clean machining.

- Servo Learning Oscillation: Standard or optional feature on all models—automatically breaks chips during turning operations for better part finishes and unattended operation.

- Automation Ready: Seamless integration with A+ Automation solutions such as OB7 Collaborative Robots, Mitsubishi LoadMate Plus™, and Fanuc CRX, as well as TRACER magazine bar feeders for long bar and lights-out production.

Specifications

| Item / Model |

SA-12B

Request a Quote |

SA-20B

Request a Quote |

SA-32B

Request a Quote |

|---|---|---|---|

|

FREE TRACER Minibar Bar Feeder Package |

FREE TRACER 20 Bar Feeder Package |

FREE TRACER 32V Bar Feeder Package | |

|

Number of Axes |

7 |

7 |

7 |

|

Number of Channels |

2 |

2 |

2 |

|

Bar Capacity (Front/Rear) |

12 mm / 12 mm |

20 mm / 20 mm |

32 mm / 32 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

3 HP |

5 HP |

10 HP |

|

Main Spindle |

10,000 RPM |

8,000 RPM |

8,000 RPM |

|

Sub Spindle |

1.5 HP |

3 HP |

3 HP |

|

Sub Spindle |

10,000 RPM |

8,000 RPM |

8,000 RPM |

|

Max. Turn Length |

6.3″ |

8″ |

8″ |

|

Total Tools |

18 |

22 |

20 |

|

Fixed Tools (Front/Rear) |

10 / 2 |

12 / 2 |

10 / 2 |

|

Live Tools (Front/Rear) |

4 / 2 |

6 / 2 |

6 / 2 |

|

Live Tools |

6,000 RPM |

6,000 RPM |

6,000 RPM |

|

Live Tools |

1.3 HP |

1.3 HP |

1.3 HP |

|

B Axis |

– |

– |

– |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC OiTF |

FANUC OiTF |

FANUC OiTF |

|

Weight |

4,180 lbs. |

5,940 lbs. |

6.820 lbs. |

Videos

Benefits for Metal Cutting and Parts Manufacturers

The Nexturn SA(B) Series delivers measurable gains in part quality, uptime, and overall machining efficiency for precision manufacturers.

With these technologies, manufacturers can expect cycle time reductions, longer tool life, and greater process reliability — key advantages for small-parts production where precision and consistency define profitability.

Ideal Cutting Applications

- Medical: Bone screws, surgical fasteners, dental implants, orthopedic pins, and precision micro-components.

- Aerospace & Defense: Hydraulic fittings, control pins, actuator shafts, and small flight-critical parts.

- Automotive: Fuel injectors, valve bodies, brake fittings, and sensor housings.

- Electronics: Connectors, miniature terminals, and contact pins.

- General Small-Parts Production: High-precision bushings, fasteners, and machined fittings requiring tight tolerances and mirror-finish surfaces.

FAQs

How are CNC Swiss lathes different from conventional lathes?

The difference between a CNC Swiss lathe and a conventional lathe is the utilization of the guide bushing. In Swiss lathes, the guide bushing gives support to the workpiece and allows for greater precision throughout the entire cutting process. Because the guide bushing holds the workpiece so close to the tool, there is essentially zero deflection due to the cutting force. With conventional lathes, stability for the part being turned decreases the further away the cutting tool is from where the machining material is being held by the chuck. This tends to result in chatter, vibration, whipping, and poorer surface finish quality. Swiss machines cut very close to the guide bushing on the main spindle side, is typically 0.20” (or 20 thousandths). This helps keep the piece extremely rigid, which makes a high quality surface finish achievable.

Why is the Swiss machine tooling capacity significant?

CNC Swiss machines can accommodate 20 or more tools in the tool zone, many with live tooling. Combined with a sub-spindle and backworking stations, this array of tools means Swiss machines can often produce finished, ready-to-ship components, eliminating the need for secondary operations on complex parts.

What is Servo Learning Oscillation on a CNC Swiss Lathe?

During the machining process, chips tend to pile up around the part or the tool. This can destroy the cutting tool or cause scratches to the outside finish of the part. Both are obviously undesirable outcomes that can be alleviated by the Servo Learning Oscillation feature on Nexturn Swiss CNC lathes. Servo Learning Oscillation constantly changes frequencies through the X, Y, and Z axes. Combining this with interrupting cutting on the part means the chips cleanly break away (hence the phrase “Breaking the Chip”) rather than allowing long stringy chips to gather around the part and cutting tool. The Servo Learning Oscillation feature is ideal for materials such as aluminum or stainless steel.