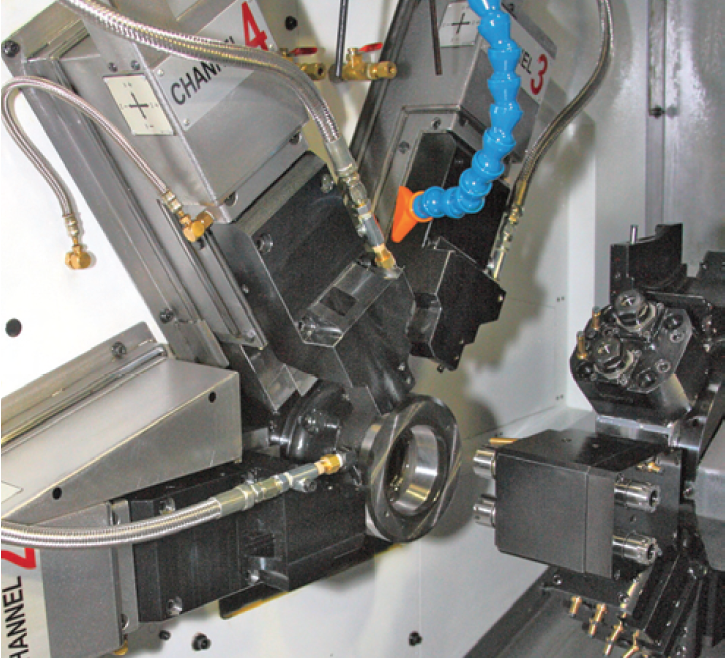

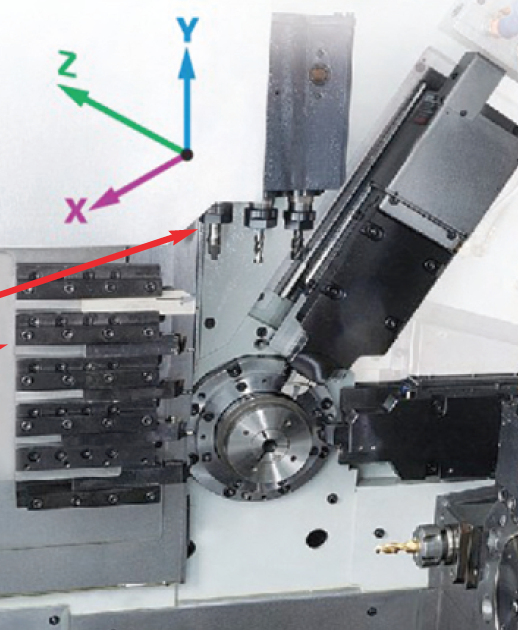

LICO LNDD Series – 12-Axis Twin Spindle Multi-Slide CNC Mill/Turn Centers

Complete Part Machining with Full Counter-Spindle and Y-Axis Capability

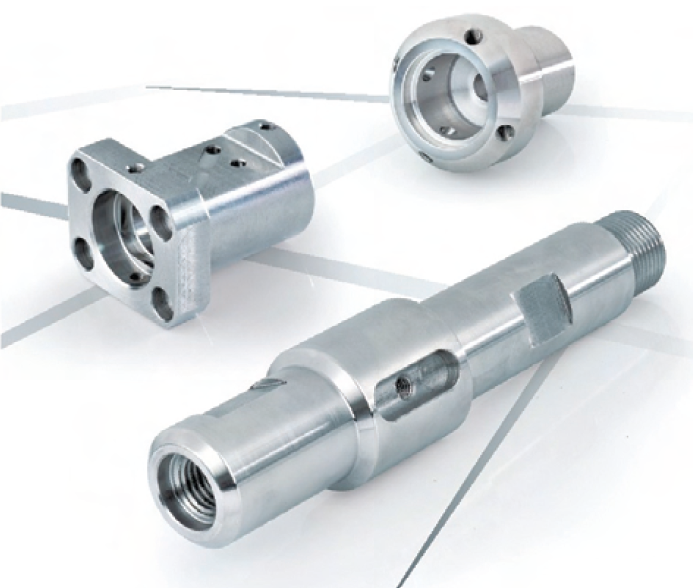

The LICO LNDD Series is a rugged, high-precision CNC multi-slide mill/turn centers designed to machine complex parts complete — all in one setup. Ideal for medium to large turned components, the LNDD delivers the flexibility of full mill/turn machining, high-speed backworking, and heavy-duty cutting with minimal cycle times.

This advanced platform combines multi-slide turning with Y-axis live tooling and a fully independent counter-spindle, making it a powerful alternative to Swiss-type machines, turret lathes, and horizontal machining centers.

Key Features

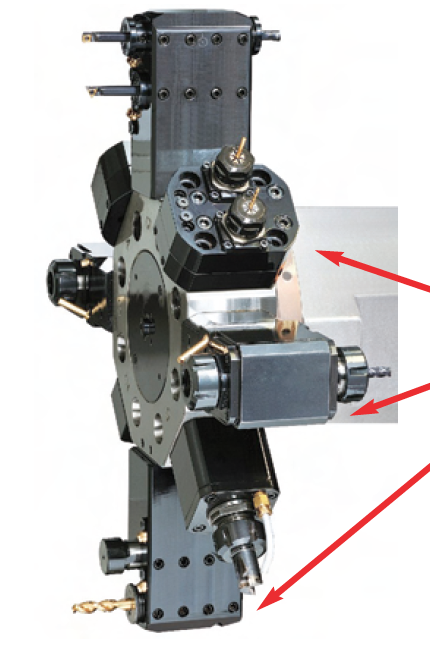

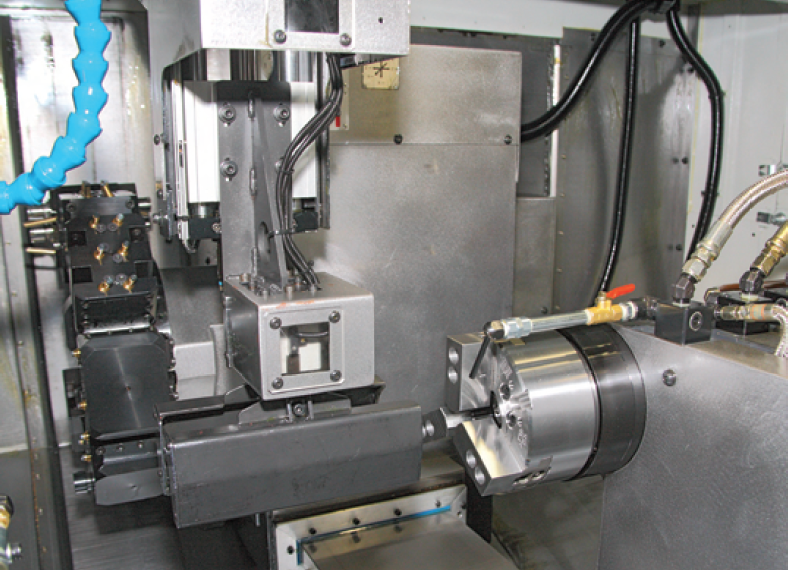

- Two 2-axis cross-slides for simultaneous roughing and finishing

- Independent counter-spindle for full part transfer and backworking

- 8-position VDI-30 live tooling turret with full Y-axis functionality

- Ideal for complex parts up to 17” in length and 4” bar capacity

- Handles overlapping operations to minimize idle time

- Rigid boxway construction for heavy cuts and long tool life

- Perfect for automotive, aerospace, medical, and general machining

Built for Complex, High-Value Parts

Whether you’re producing tight-tolerance medical components or multi-featured aerospace parts, the LNDD Series combines the speed of a multi-slide CNC lathe with the versatility of a Y-axis turning center — all in a single footprint.

Request a quote today and see how the LNDD Series can reduce setups, shrink cycle times, and maximize spindle uptime.

Specifications

| Item / Model |

LND51D

Request a Quote |

LND65D

Request a Quote |

LND80D

Request a Quote |

LND100D

Request a Quote |

|---|---|---|---|---|

|

Bar Capacity ∅ Thru Bore |

51 mm (2.00″) |

65 mm (2.56″) |

80 mm (3.15″) |

100 mm (3.94″) |

|

Max Turning Length |

450 mm (17.7″) |

450 mm (17.7″) |

450 mm (17.7″) |

450 mm (17.7″) |

|

Main Spindle | ||||

|

Collet Chuck Type |

Hainbuch 52 |

B65 |

F90 |

F112 |

|

Spindle Nose |

A2-5 |

A2-6 |

A2-8 |

A2-8 |

|

Motor Power (Continuous) |

15 kW (20 HP) |

15 kW (20 HP) |

15 kW (20 HP) |

15 kW (20 HP) |

|

Max. Spindle Speed |

5,000 RPM |

4,000 RPM |

3,000 RPM |

2,500 RPM |

|

Counter Spindle | ||||

|

Collet Chuck Type |

B42 (42mm thru) / B65 (65mm thru) / 6″ 3-Jaw Chuck (65mm thru) |

B42 (42mm thru) / B65 (65mm thru) / 6″ 3-Jaw Chuck (65mm thru) |

B42 (42mm thru) / B65 (65mm thru) / 6″ 3-Jaw Chuck (65mm thru) |

B42 (42mm thru) / B65 (65mm thru) / 6″ 3-Jaw Chuck (65mm thru) |

|

Spindle Nose |

A2-5 |

A2-5 |

A2-5 |

A2-5 |

|

Motor Power (Continuous/Peak) |

7 kW (9.4 HP) / 10 kW (13.4 HP) |

7 kW (9.4 HP) / 10 kW (13.4 HP) |

7 kW (9.4 HP) / 10 kW (13.4 HP) |

7 kW (9.4 HP) / 10 kW (13.4 HP) |

|

Max. Spindle Speed |

5,000 RPM |

5,000 RPM |

5,000 RPM |

5,000 RPM |

|

Z-Axis Slide Travel |

450 mm (17.7″) |

450 mm (17.7″) |

450 mm (17.7″) |

450 mm (17.7″) |

|

Slide Motor Power |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

|

Cross Slide | ||||

|

X-Axis Travel (standard) |

70 mm (2.76″) |

70 mm (2.76″) |

70 mm (2.76″) |

70 mm (2.76″) |

|

X-Axis Travel (extended opt.) |

110 mm (4.33″) |

110 mm (4.33″) |

110 mm (4.33″) |

110 mm (4.33″) |

|

Z-Axis Travel |

115 mm (4.53″) |

115 mm (4.53″) |

115 mm (4.53″) |

115 mm (4.53″) |

|

Motor Power |

0.5 kW (0.7 HP) |

0.5 kW (0.7 HP) |

0.5 kW (0.7 HP) |

0.5 kW (0.7 HP) |

|

Rapid Traverse |

15 meters/min. (590″/min.) |

15 meters/min. (590″/min.) |

15 meters/min. (590″/min.) |

15 meters/min. (590″/min.) |

|

Max. Feed Rate |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

5 meters/min. (197″/min.) |

|

Turret Slide | ||||

|

Tool Positions |

8 |

8 |

8 |

8 |

|

Tool Shank Type |

20mm (3/4″ square)/1″ (round)/VDI-30 |

20mm (3/4″ square)/1″ (round)/VDI-30 |

20mm (3/4″ square)/1″ (round)/VDI-30 |

20mm (3/4″ square)/1″ (round)/VDI-30 |

|

Indexing Time |

0.4 sec. / 180° – 1.2 sec. |

0.4 sec. / 180° – 1.2 sec. |

0.4 sec. / 180° – 1.2 sec. |

0.4 sec. / 180° – 1.2 sec. |

|

Live Motor Tool Power |

5 HP |

5 HP |

5 HP |

5 HP |

|

Live Tool Max. Speed |

3,000 RPM |

3,000 RPM |

3,000 RPM |

3,000 RPM |

|

X-Axis Travel |

175 mm (6.9″) |

175 mm (6.9″) |

175 mm (6.9″) |

175 mm (6.9″) |

|

Z-Axis Travel |

475 mm (18.7″) |

475 mm (18.7″) |

475 mm (18.7″) |

475 mm (18.7″) |

|

X/Z Axis Motor Power |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

2.3 kW (3.0 HP) |

|

Y-Axis Travel (opt.) |

±55 mm (±2.16″) |

±55 mm (±2.16″) |

±55 mm (±2.16″) |

±55 mm (±2.16″) |

|

Y-Axis Motor Power |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

|

Machine | ||||

|

Dimensions (LxWxH) |

3185 x 1890 x 1875mm (125.4″ x 74.4″ x 74″) |

3185 x 1890 x 1875mm (125.4″ x 74.4″ x 74″) |

3185 x 1890 x 1875mm (125.4″ x 74.4″ x 74″) |

3185 x 1890 x 1875mm (125.4″ x 74.4″ x 74″) |

|

Weight |

4,500 kg (10,000 lbs.) |

4,500 kg (10,000 lbs.) |

4,700 kg (10,350 lbs.) |

4,700 kg (10,350 lbs.) |

|

Hydraulic Tank Capacity |

30 L (8 gallons) |

30 L (8 gallons) |

30 L (8 gallons) |

30 L (8 gallons) |

|

Hydraulic Pump Motor |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

1.5 kW (2.0 HP) |

|

Coolant Tank Capacity |

200 L (53 gallons) |

200 L (53 gallons) |

200 L (53 gallons) |

200 L (53 gallons) |

|

Flood Coolant Motor |

1.27 kW (1.7 HP) |

1.27 kW (1.7 HP) |

1.27 kW (1.7 HP) |

1.27 kW (1.7 HP) |

|

High Pressure Coolant Motor |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

2.2 kW (3 HP) |

|

High Pressure Coolant Flow |

18L/min. @ 70kg/cm2 (5 gal/min. @ 1,000 PSI |

18L/min. @ 70kg/cm2 (5 gal/min. @ 1,000 PSI |

18L/min. @ 70kg/cm2 (5 gal/min. @ 1,000 PSI |

18L/min. @ 70kg/cm2 (5 gal/min. @ 1,000 PSI |

|

Lubrication Capacity |

8 L Tank (15 cc / 15 sec.) |

8 L Tank (15 cc / 15 sec.) |

8 L Tank (15 cc / 15 sec.) |

8 L Tank (15 cc / 15 sec.) |

|

Total Power Used |

30 kVA |

30 kVA |

38 kVA |

38 kVA |

FAQs

How does screw machine speed compare to a LICO design?

The honest truth is that parts that have 0-15 second cycle times are not typically as fast with a LICO. Cycle times that are 15-30 seconds are sometimes just as fast as an Acme or Brown and Sharpe. But LICO is definitely the fastest when it comes to any part that has a 30-second or more cycle time. However, we have had reports from a few customers that tell us they have compared parts with cycle times at 0-15 seconds, and some ran faster on the LICO. So it boils down to part design and set up. That’s why a time study on the part is so very important. Absolute Machine Tools has Swiss lathes, mill/turn centers, and multi-slide CNC machines. We don’t favor one over the other, we favor the most cost-effective engineered solution because it gives the end user the best value.

What do customers say about LICO multi-slide CNC machines?

One customer in particular that has multiple LICO multi-slide CNC machines had a particular part that was running 8.5 seconds on their Acme screw machines. Absolute Machine Tools performed a time study, set the machine up in our showroom, and ran that same part. Our applications engineers were able to run the part achieving a 200-300% throughput increase resulting in 3x reduction in manpower. The savings in manpower alone afforded them multiple new machine purchases. The customer had been utilizing one operator per Acme machine, hand-deburring each part, and washing and packing them for shipment. The operators were also having to load the machines with material so frequently that it was resulting in spindle utilization time just under 50%. Today those 1.5 operators are now tending 5 LICO machines. Quantifying a savings of 3.5 operators and a 200-300% throughput rate has afforded the customer the ability to justify additional LICO machines. Throughput is putting good parts in the pan at the end of the day. It doesn’t do a shop any good to run parts it can’t sell. The ability to combine CNC quality, multiple cuts simultaneously in material, and dropping parts totally complete greatly benefits and their ROI.

Why not use a tumbler to debur?

Tumblers work as well, especially when deburring the OD of a part. But what about when a customer’s parts needed to debur the ID? Even if you use small media in the tumbler to do this, it’s not as effective, and sometimes the small media gets stuck in the parts or rolls the bur to the end of the ID. Being able to cut the ID without leaving and burrs or marks is the best solution.

Why not consider a Hydromat-style CNC machine over a CNC screw machine?

Hydromat machines are best used for parts that are under ½”. They are good machines but not inexpensive. However, if running lights out or 3 shifts, the more complex the work gets, the better chance of that making economic sense. This is when a time study makes a lot of sense because there are shops that have taken very inexpensive Swiss machines and moved some of their 00 work to them.

How do you calculate an ROI for CNC screw machines?

Being able to perform an ROI for a customer is key in making the argument to buy a new CNC machine from Absolute Machine Tools. Over the years, our production turning applications engineering team has developed in-depth spreadsheets. First, we calculate the cost of running the current job on the customer’s machine using their hours and dollars. Then, we calculate the cost of running the part in one, two, or even three operations, or however many ops it currently takes them to complete the part. We’ll calculate spindle utilization time as well. Next, we use this information to calculate the same on our production turning products in a one-and-done scenario. That way a customer can clearly see in black and white, using data they supplied, how our machine and process can return a healthy ROI. Once we present real numbers, they have the opportunity to act upon it or not. Some people reading this will say that it is easy for us to manipulate our numbers in our favor. However, it does no behoove us to manipulate the numbers just to sell one or many machines. Our job is to educate customers about the different solutions. If the current solution doesn’t pencil out, we can always go back and look at a different type of machine. Our goal is a satisfied customer who outperforms everybody else.

In Stock and Ready for Immediate Delivery

Power specifications can change without prior notice. Mitsubishi CNC Controls are standard, FANUC and Siemens CNC Controls are optional.