Johnford

Machinery

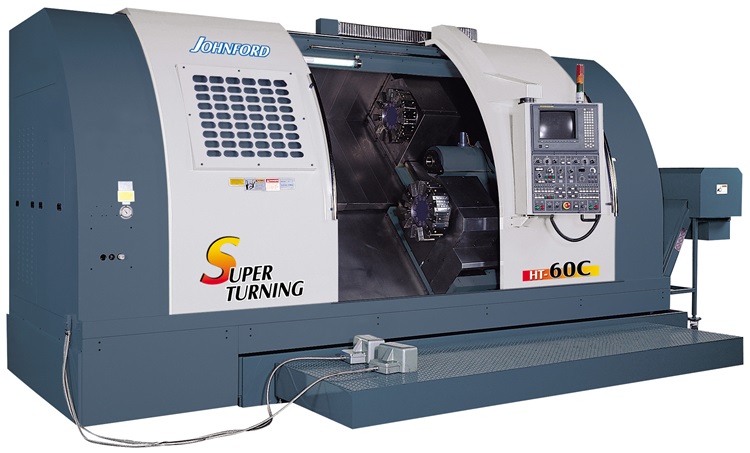

Johnford Bridge Mills, Boring Mills, & Large Lathes

Johnford has been a worldwide leader in CNC machine tool manufacturing for almost 40 years due to their exceptional quality and flexibility. The company is known for their heavy-duty workhorse CNCs, as well as for their custom-made machines that have been placed throughout the global market. Johnford’s heavy casting, poured in their own foundry, delivers unsurpassed rigidity and longevity.

Absolute Machine Tools has been proudly representing Johnford since 1992 and has serviced, sold, and installed over 3,000 Johnford CNC machines within the U.S. and around the world in such countries as Mexico, Canada, Romania, Singapore, and China.

Johnford Manufacturing Solutions:

Machines

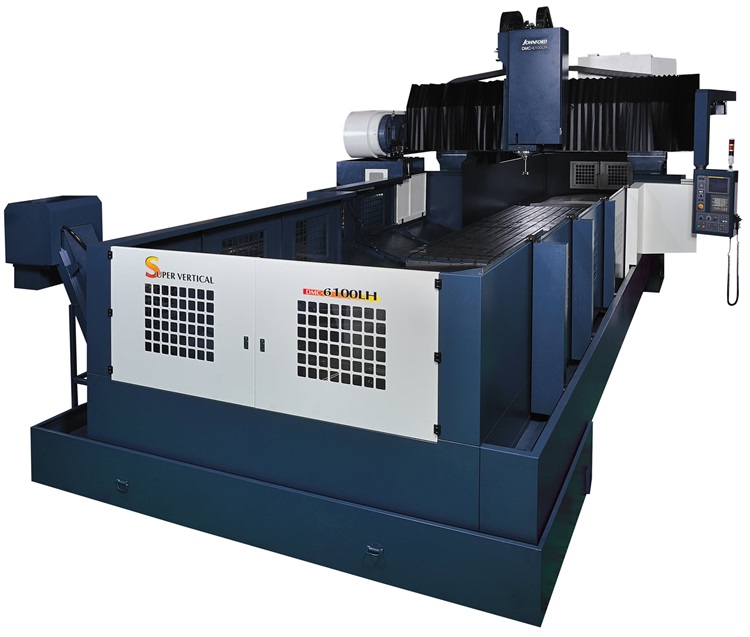

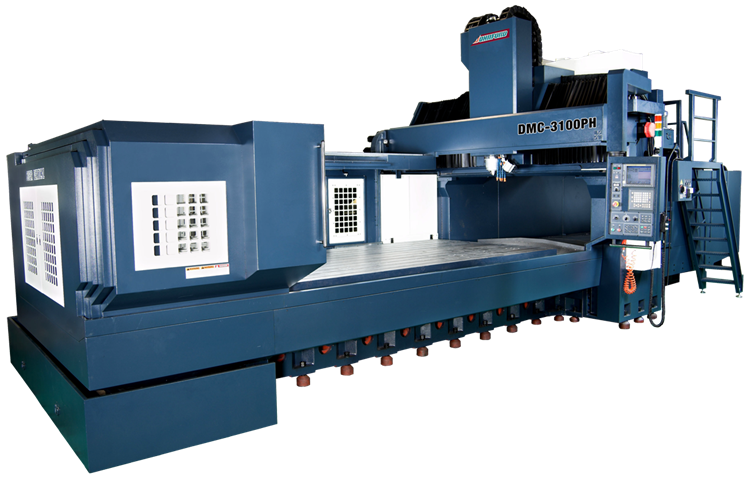

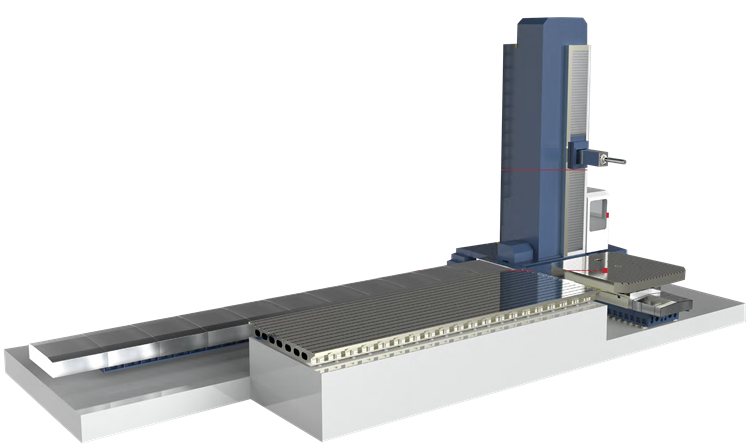

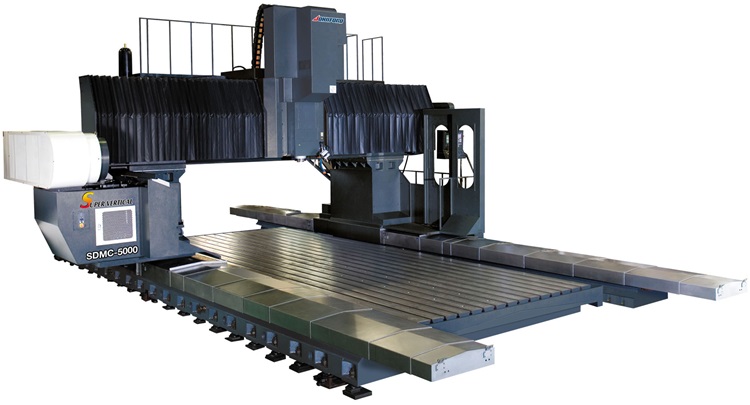

Massive Fixed or Moving Table/Fixed Column Bridge Mills

5-Sided/5-Axis Options for Specific Johnford DMC Models