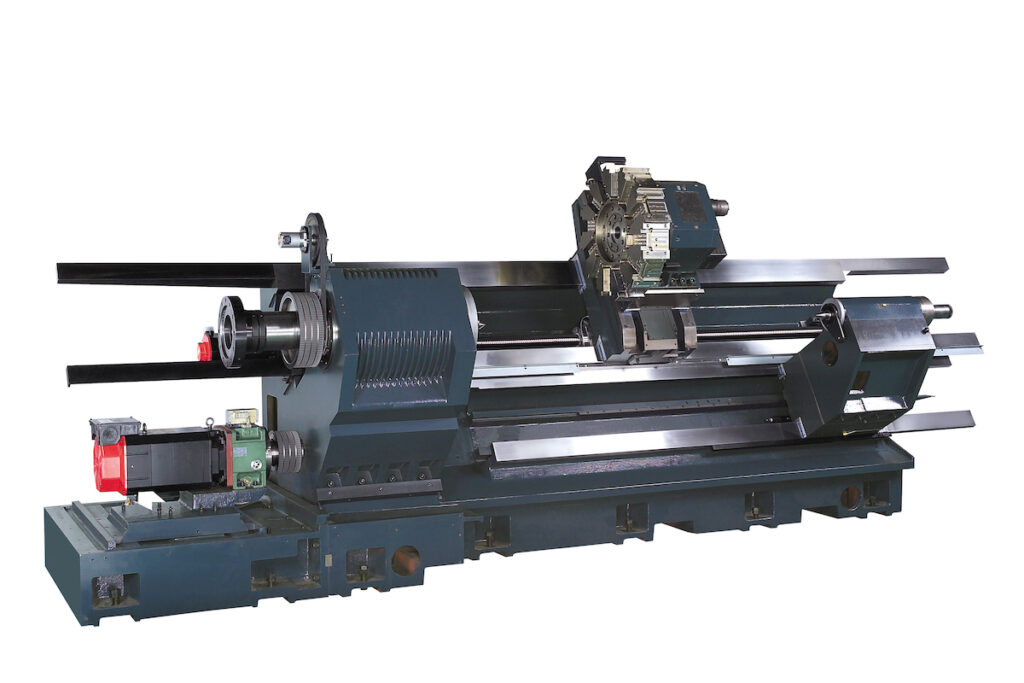

Johnford ST Series – 60 Degree Horizontal Slant Bed Turning Centers

Johnford ST Series horizontal turning centers feature a one piece, 60˚ slant-bed torque tube design. The torque tube, or hole cast through the center of the slant bed, maximizes rigidity and dissipates heat. For optimum strength and accuracy, the machines are cast from rigid Meehanite iron.

Swing over the bed for the 28-machine series ranges from 31″ (533 mm) to 47.2 ” (1,199 mm). Swings over the cross slide are 23.6″ (600 mm) to 39.4″ (1,000 mm). Distance between centers begins at 40″ (1,016 mm) and is 400″ (10,160 mm) on the largest machine.

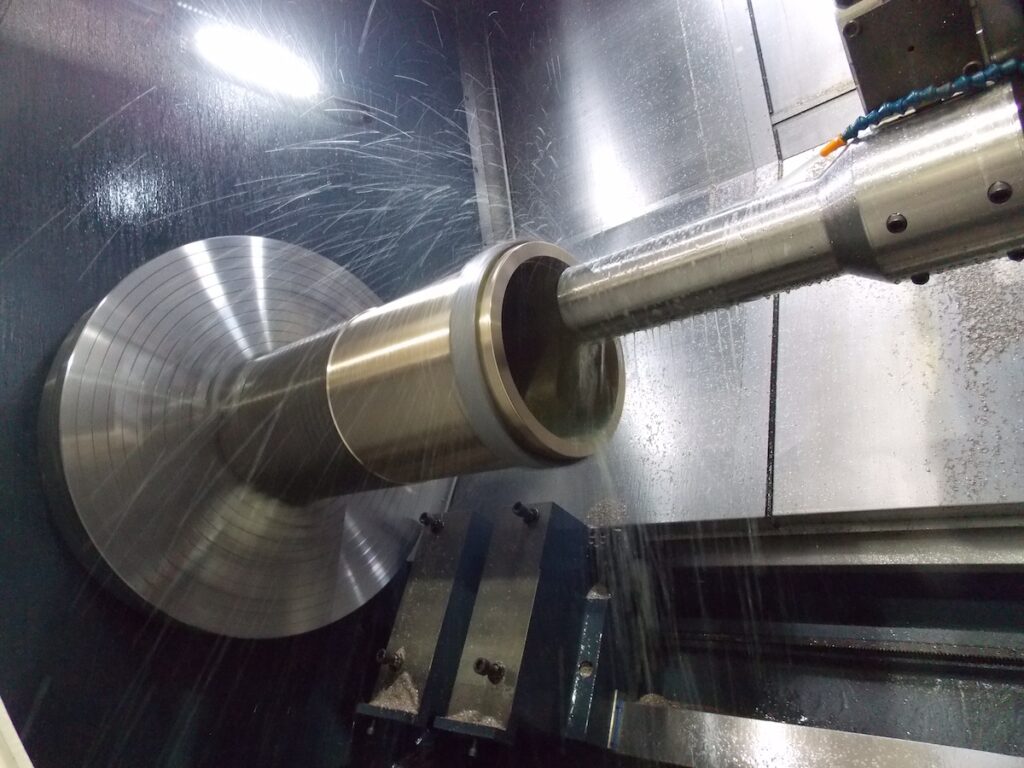

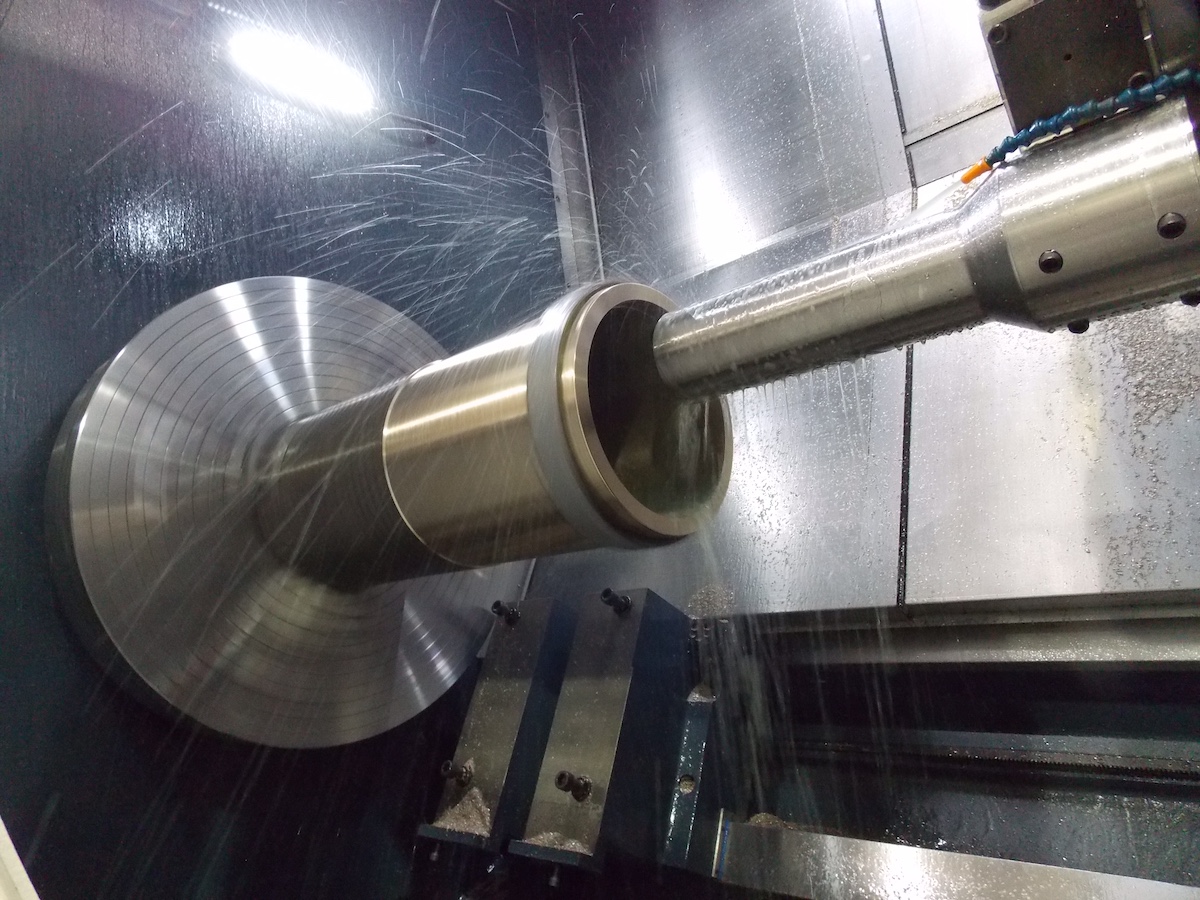

Square box ways provide rigidity for heavy turning, and hand-scraped sliding surfaces are coated with Turcite B to enable high rapid traverse rates and accurate positioning. Double-nut ballscrews are pre-tensioned to minimize thermal growth.

To ensure precision and thermal stability, the headstock, tailstock and saddle all are mounted on the same plane at a 60˚ angle. The coolant tank is separate from the machine base to prevent heat transfer from the coolant to the machine casting, minimizing the effect of changing temperatures and facilitating cleanout and maintenance.

Spindle power in the series ranges from 35-60 hp, delivered through a 2-4 speed gearbox that delivers high torque at low rpm. An extensive range of spindle types and sizes is available.

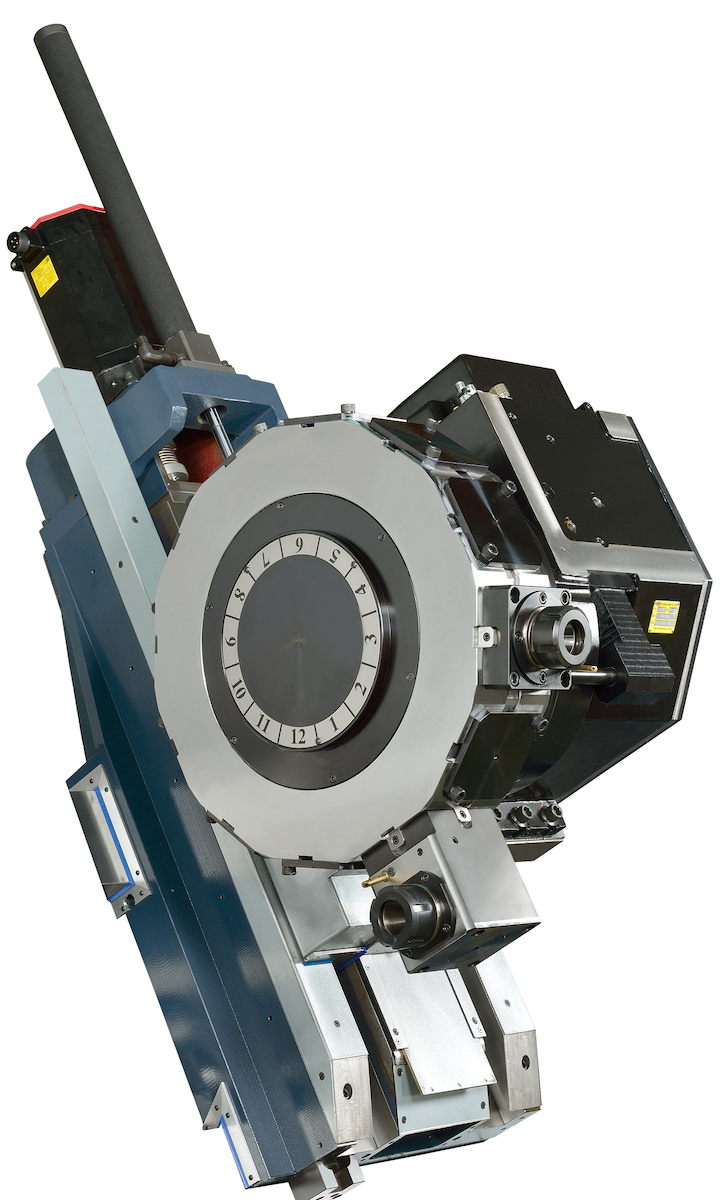

Standard features include a 20″ (508 mm) chuck, a complete coolant system, and a programmable hydraulic tailstock and quill. Among optional features are 12-station live tooling with a full C-axis spindle, Y-axis capability, axial and radial live tool heads, and 300 psi/ 1,000 psi high pressure coolant systems.

Specifications

| Item / Model |

ST-40H

Request a Quote |

ST-60H

Request a Quote |

ST-70H

Request a Quote |

ST-80H

Request a Quote |

ST-100H

Request a Quote |

ST-130H

Request a Quote |

ST-160H

Request a Quote |

ST-200H

Request a Quote |

ST-240H

Request a Quote |

ST-40X

Request a Quote |

ST-60X

Request a Quote |

ST-70X

Request a Quote |

ST-80X

Request a Quote |

ST-100X

Request a Quote |

ST-130X

Request a Quote |

ST-160X

Request a Quote |

ST-200X

Request a Quote |

ST-240X

Request a Quote |

ST-400JX

Request a Quote |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Swing Over Bed (in.) |

36.2 |

36.2 |

36.2 |

39.4 |

39.4 |

39.4 |

39.4 |

39.4 |

39.4 |

40.2 |

40.2 |

40.2 |

47.2 |

47.2 |

47.2 |

47.2 |

47.2 |

47.2 |

47.2 |

|

Swing Over Cross Slide (in.) |

27.6 |

27.6 |

27.6 |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

31.5 |

39.4 |

39.4 |

39.4 |

39.4 |

39.4 |

39.4 |

39.4 |

|

Center Distance (in.) |

40 |

54 |

69 |

80 |

100 |

130 |

160 |

200 |

240 |

40 |

54 |

69 |

80 |

100 |

130 |

160 |

200 |

240 |

400 |

|

Spindle Types |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

A,B,C,D,E,F,G,H,I,J |

|

Turret Tool Capacity |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

|

Spindle HP |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

35 – 60 |

60 |

|

Spindle Drive |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

2/4 Speed Gear Box |

4 speed gearbox |

|

C Axis |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Y Axis |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Sub Spindle |

No |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Twin Turrets |

No |

No |

No |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

No |

No |

No |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Optional – Hex |

Single |

|

Weight (lbs.) |

24,200 |

26,260 |

29,040 |

33,220 |

36,520 |

44,440 |

53,240 |

62,040 |

70,840 |

24,640 |

26,840 |

29,260 |

33,440 |

36,740 |

44,660 |

53,460 |

62,260 |

71,060 |

134,200 |

|

Spindle |

Spindle ID |

Draw Tube ID |

RPM(Max) |

Bearing ID |

Chuck Size |

|

A (A2-11) |

4.5” |

4.01” |

3000 |

6.3” |

12”~18” hyd. |

|

B (A2-11) |

5.2” |

4.56” |

2000 |

7.1” |

15”~24” hyd. |

|

C (A2-15) |

5.98” |

5.47” |

1500 |

7.87” |

20”~32” hyd. |

|

D (A2-15 |

7.28” |

6.5” |

1000 |

9.45” |

20”~32” hyd. |

|

E (A2-15) |

9.29” |

8” |

800 |

11.02” |

24”~40” hyd. |

|

F (A2-20) |

10” |

—- |

500 |

12.5” |

24”~40” man. |

|

G (A2-20) |

12.5” |

—- |

500 |

14” |

24”~40” man. |

|

H (A2-20) |

14” |

—- |

400 |

16” |

28”~40” man. |

|

I (A2-28 |

16” |

—- |

350 |

18.5” |

32”~48” man. |

|

J (A2-28) |

21” |

—- |

250 |

24” |

32”~48” man. |

|

K(A2-32) |

24” |

—- |

200 |

27” |

36”~48” man. |