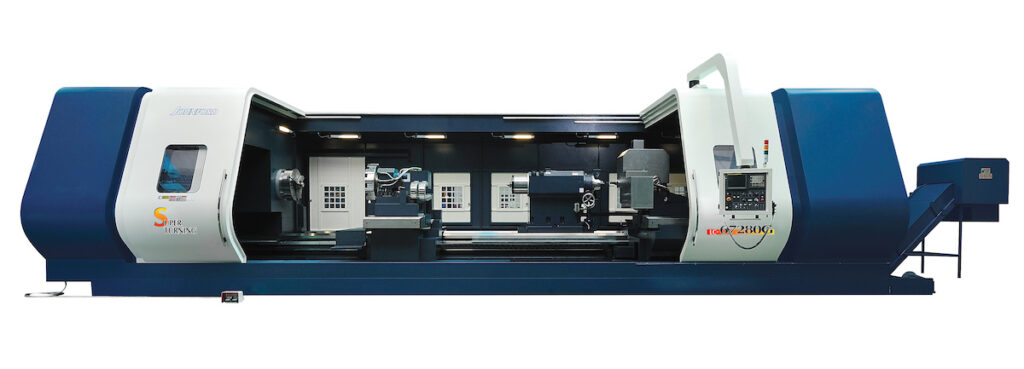

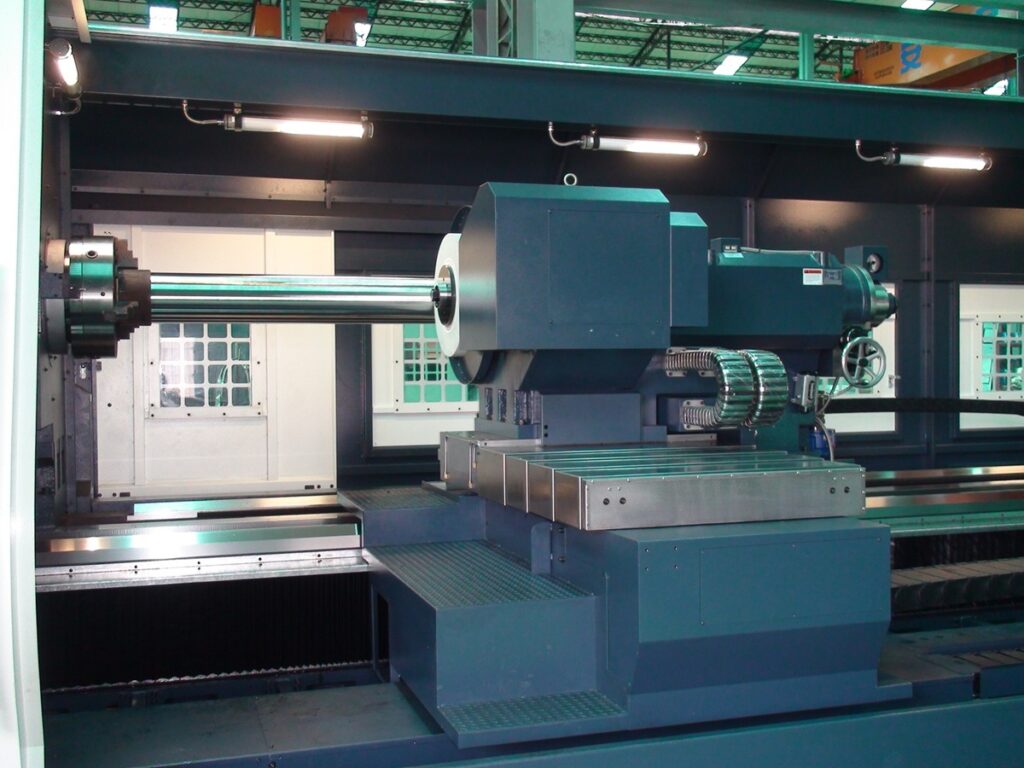

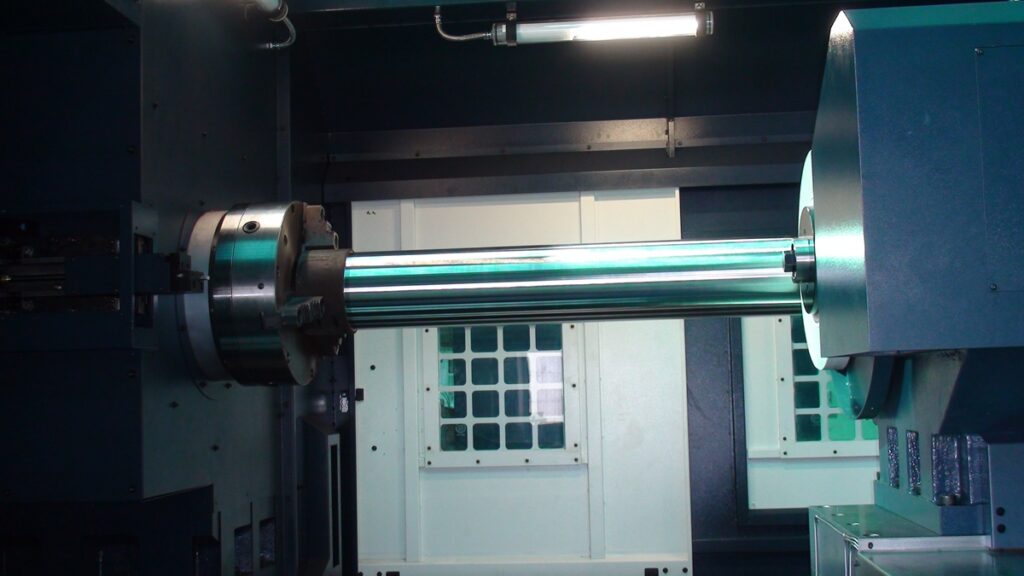

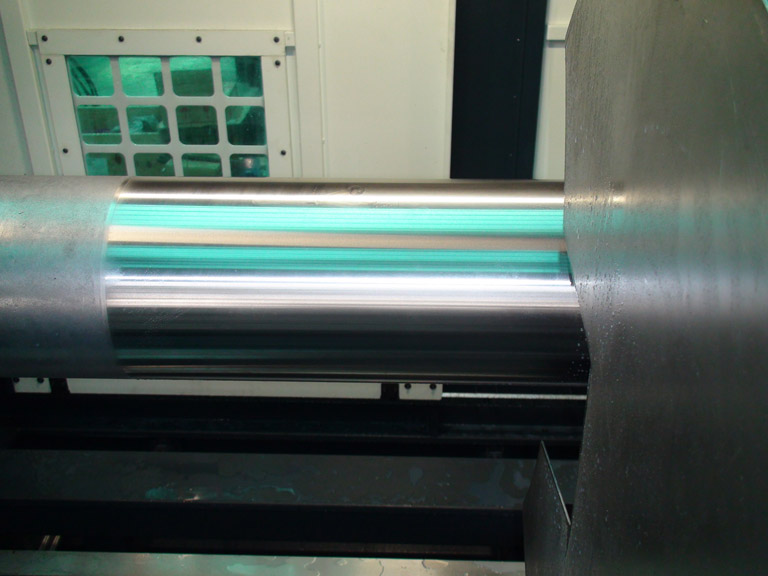

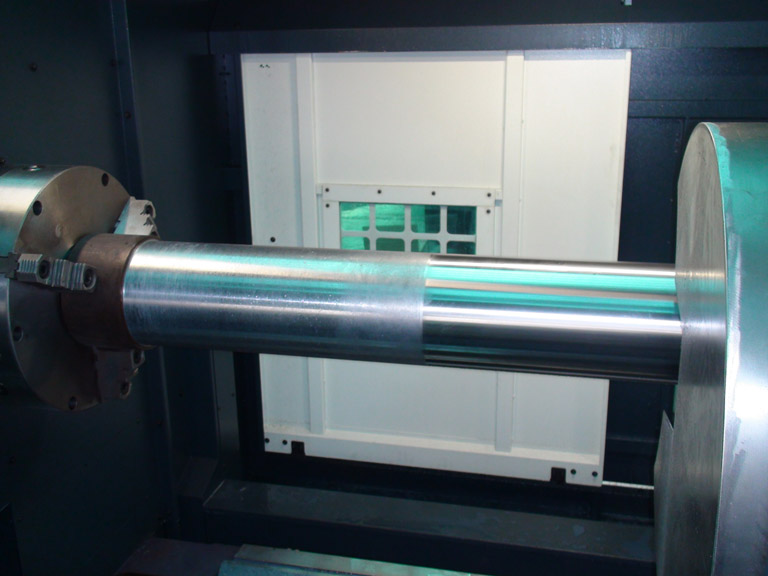

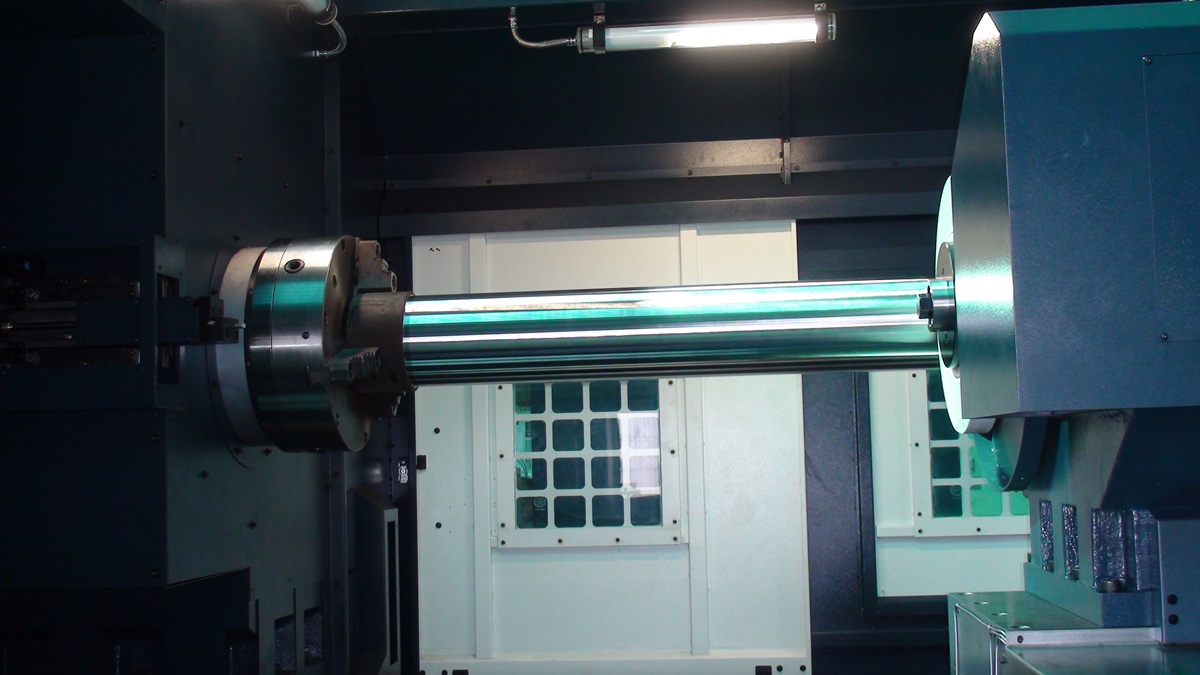

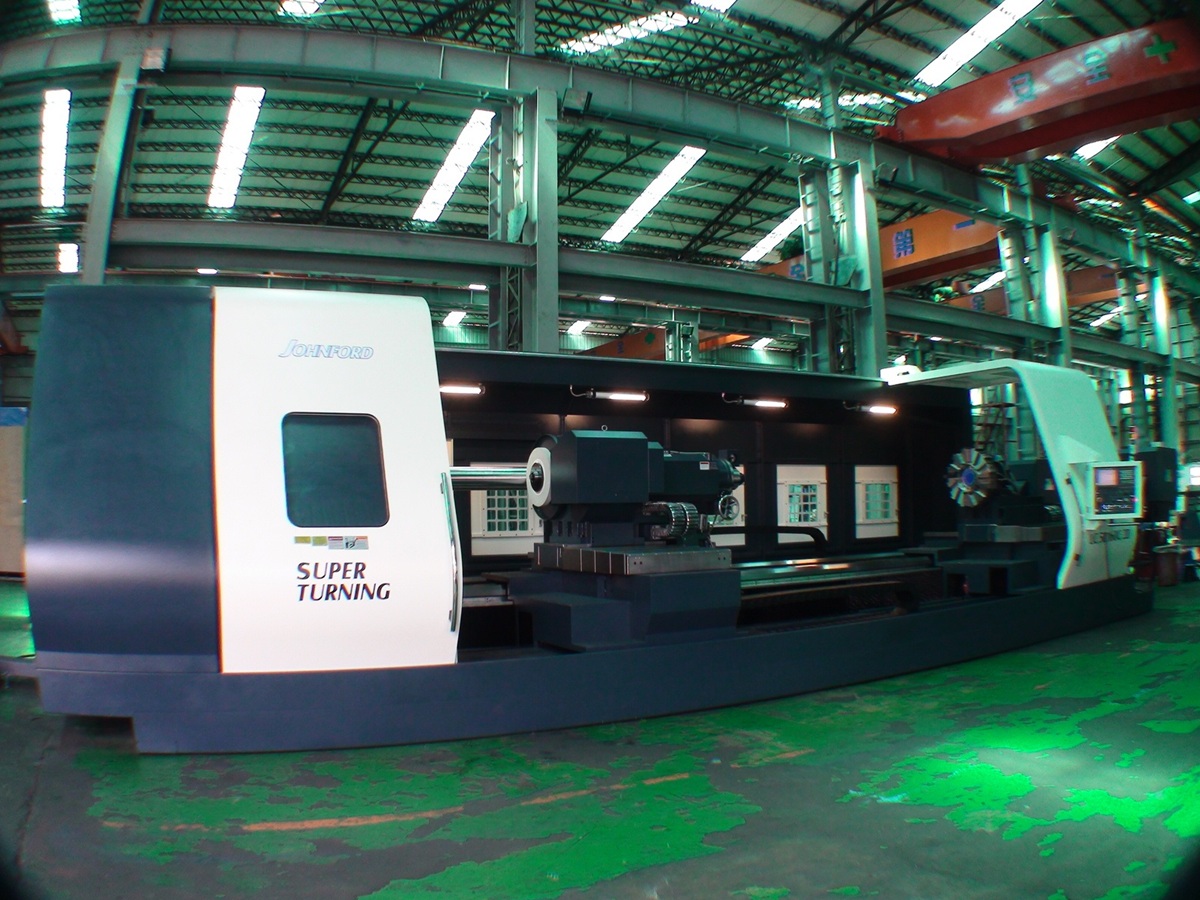

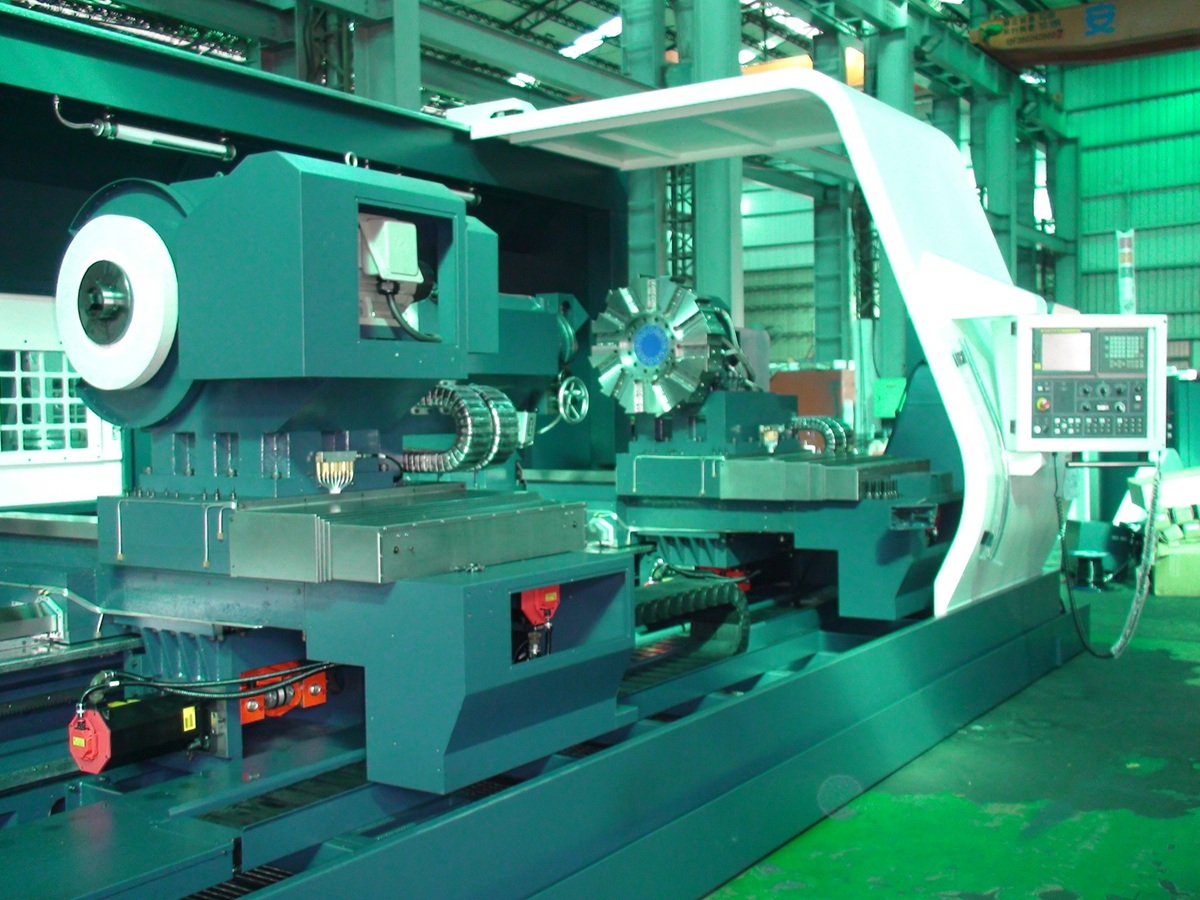

Built to Turn the Longest and Heaviest Workpieces with Precision

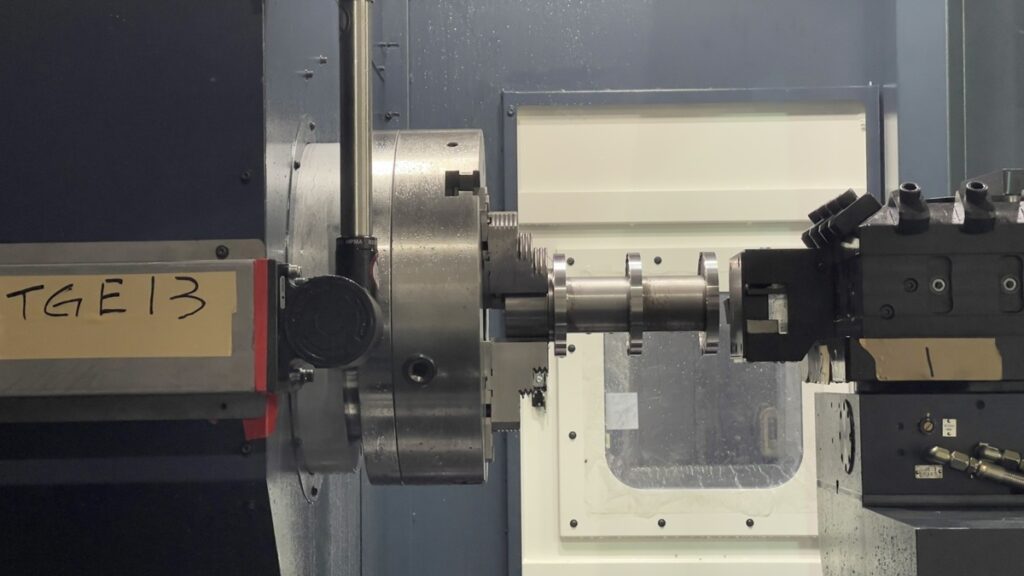

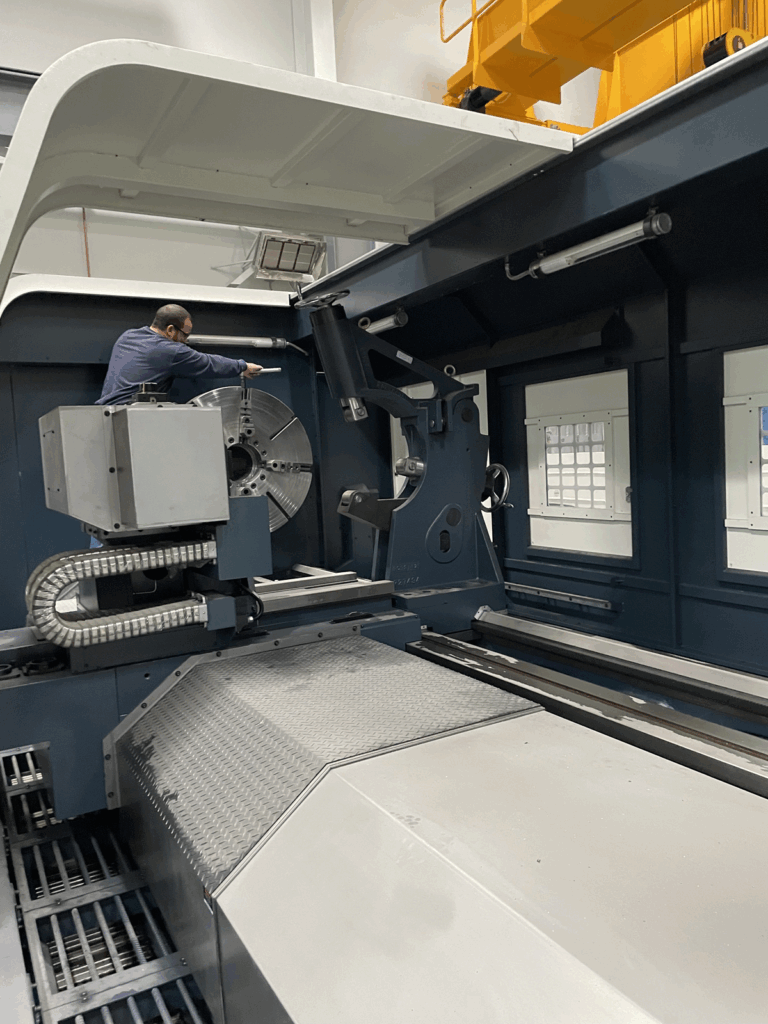

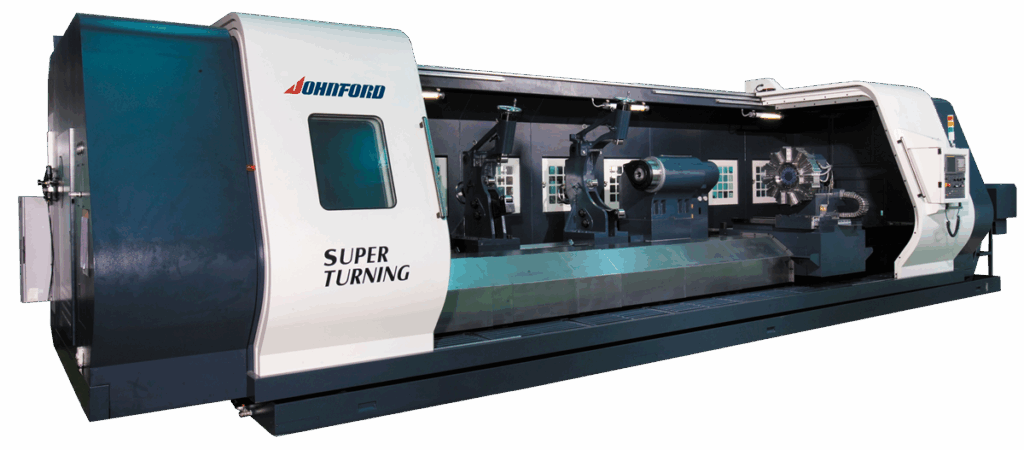

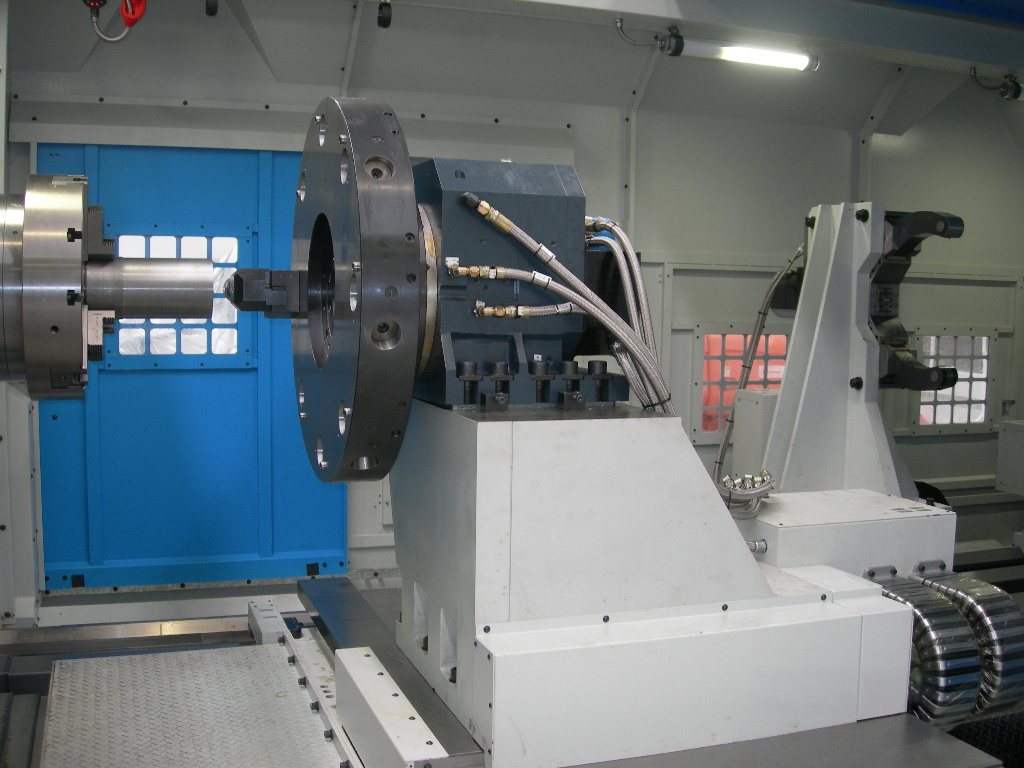

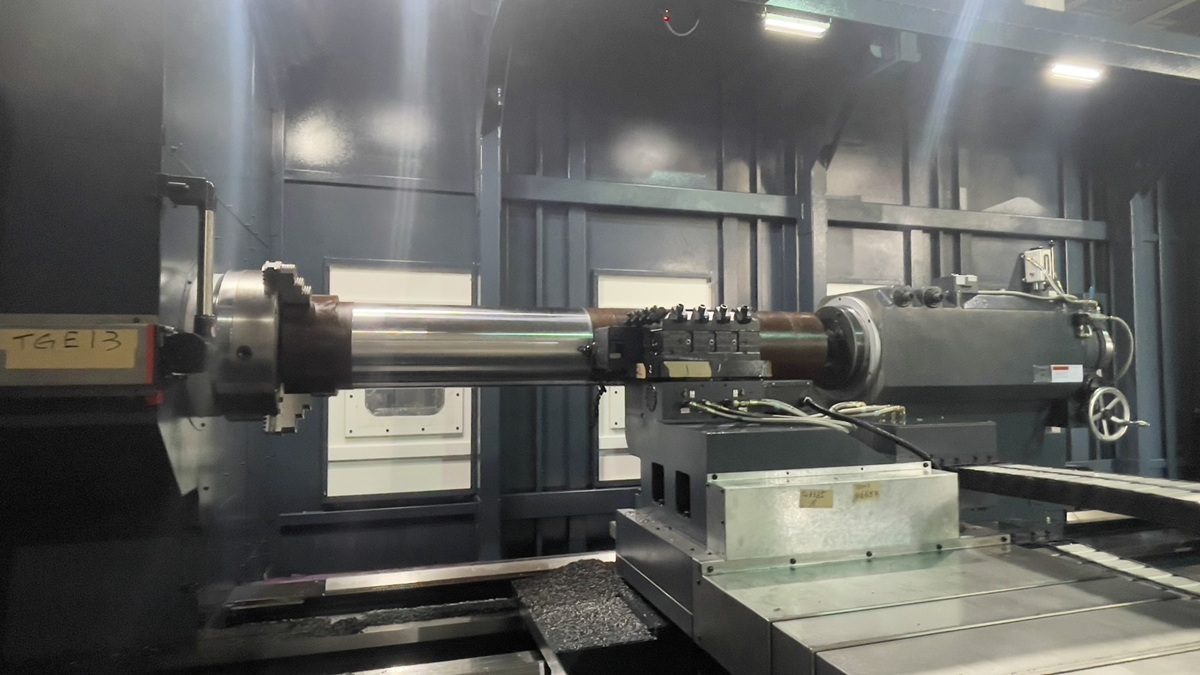

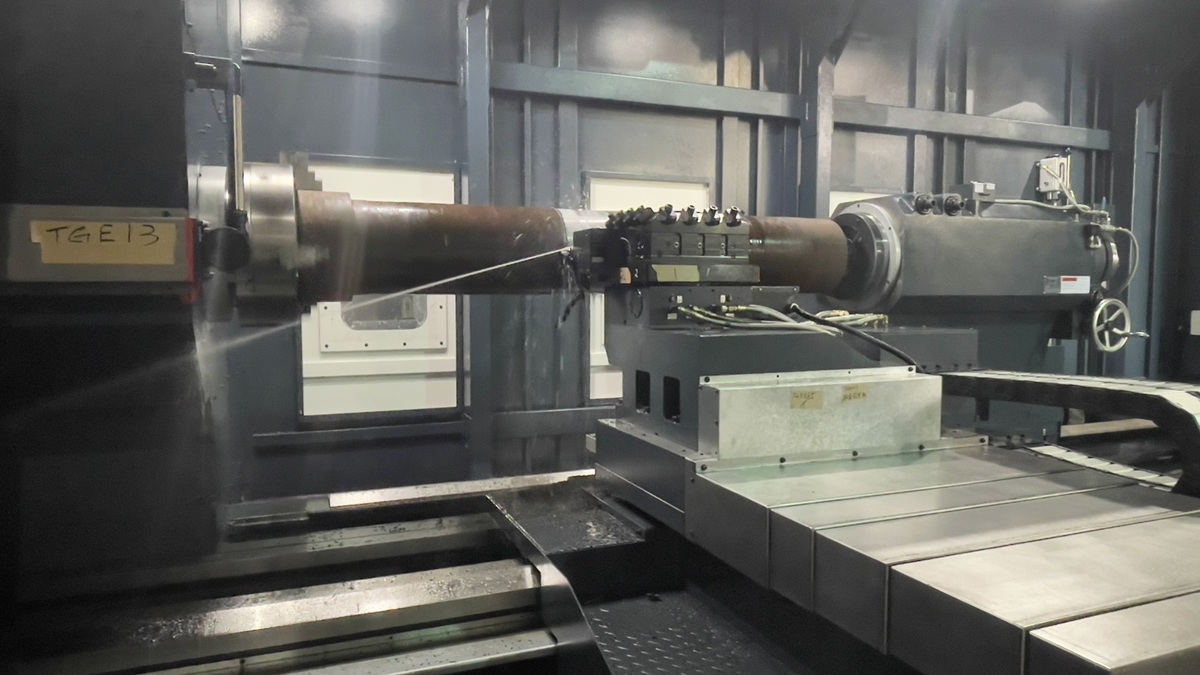

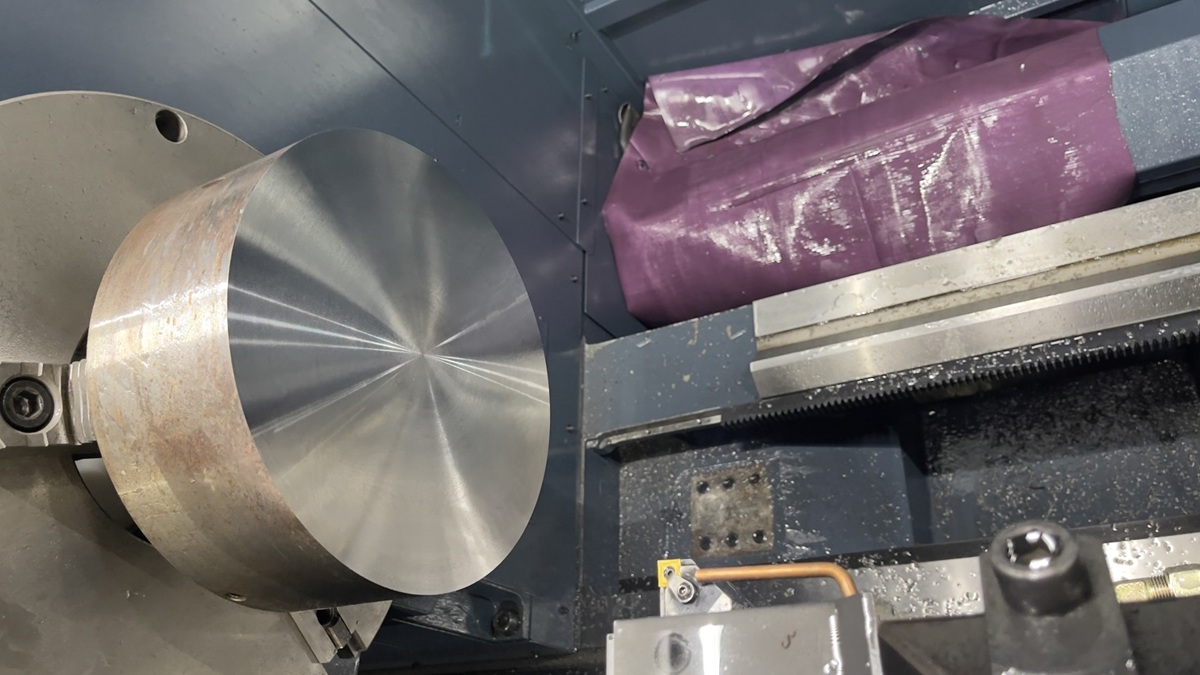

The Johnford LC Series is a heavy-duty line of large flat bed CNC lathes designed specifically for long-part turning. Whether you’re machining power transmission shafts, aerospace components, or structural rollers, the LC Series delivers industry-leading rigidity and travel capacity.

With swing capacities from 40″ to 90″ and unmatched center distances up to 788″, these machines are ideal for long shaft turning, large part machining, and heavy-duty horizontal turning.

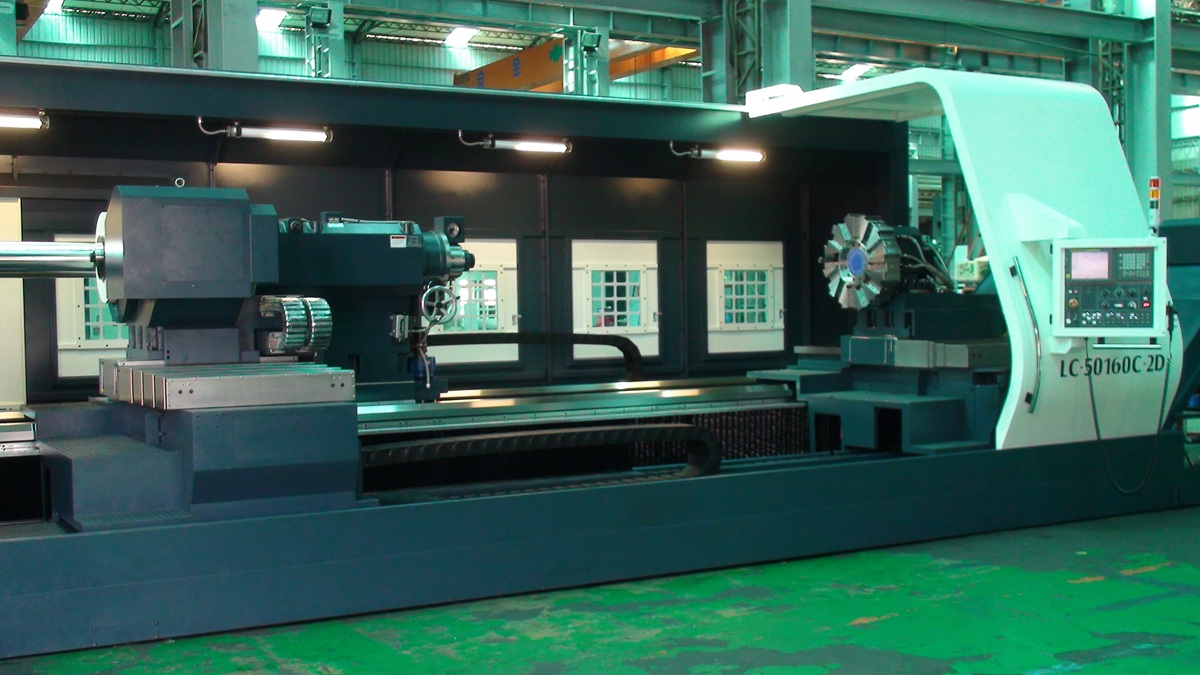

Key Features

Massive Swing and Travel Capacities

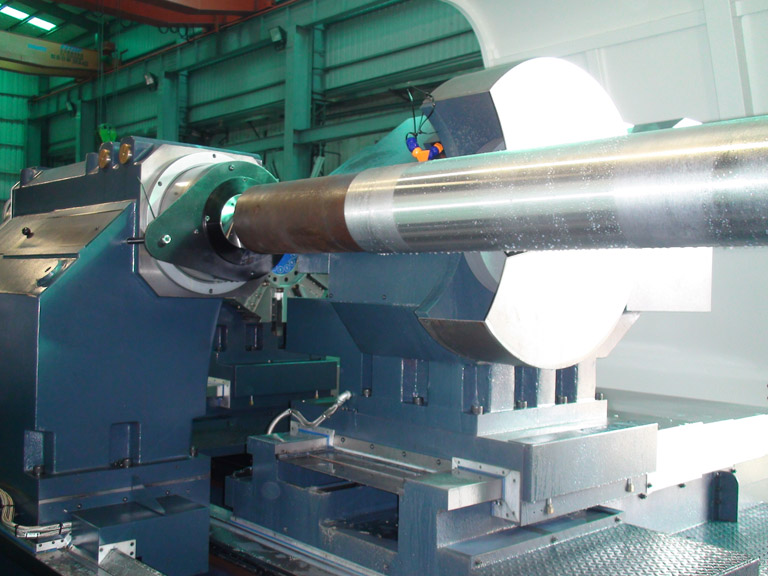

Heavy-Duty Meehanite Construction

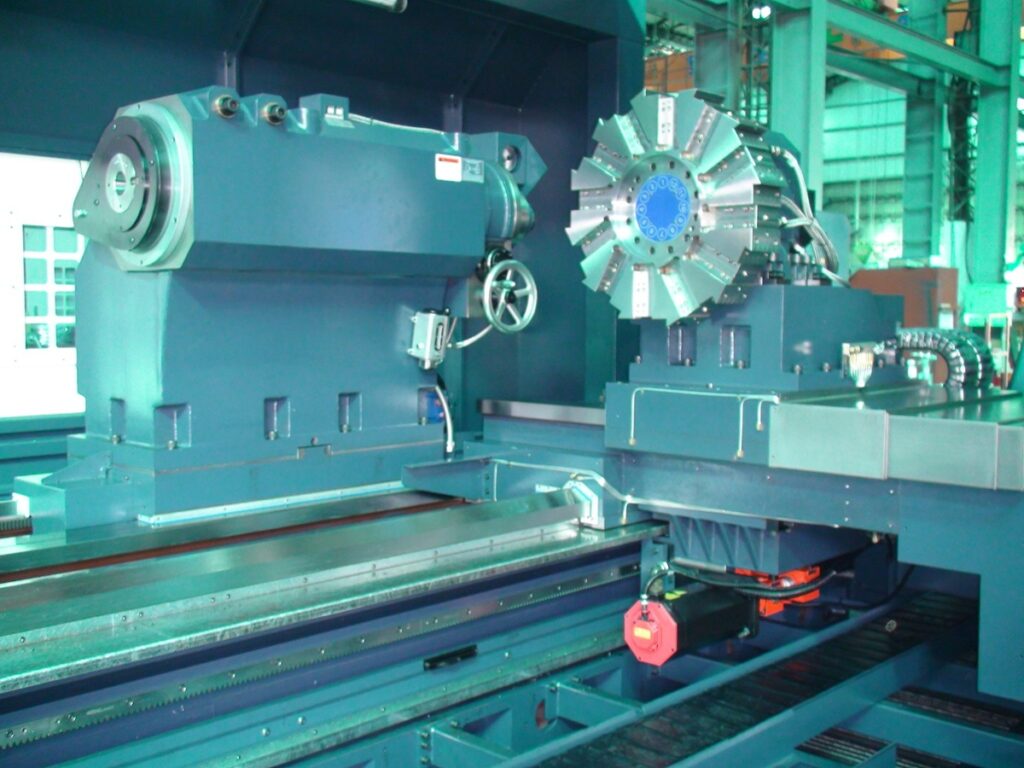

High-Torque Gear-Driven Spindle

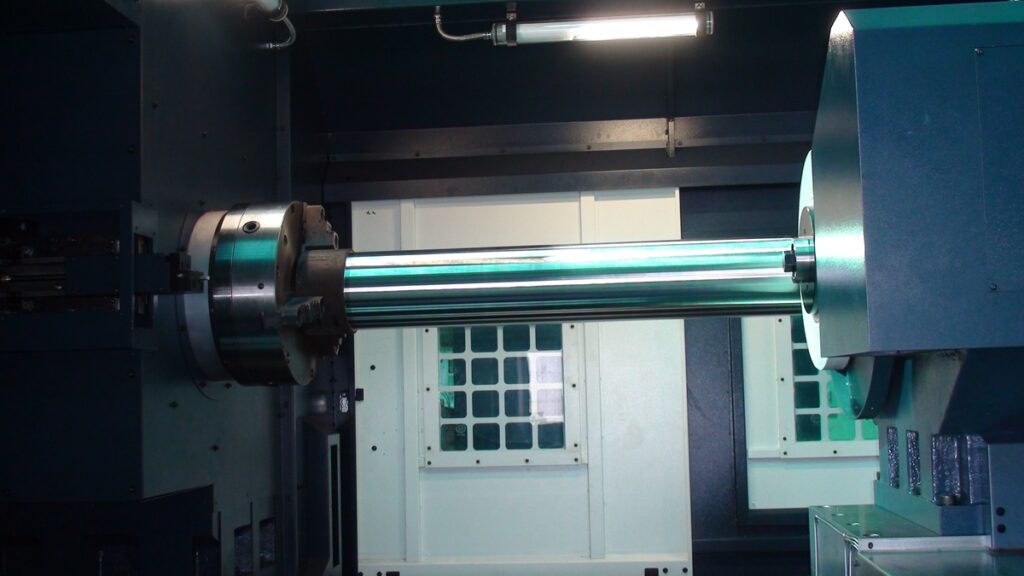

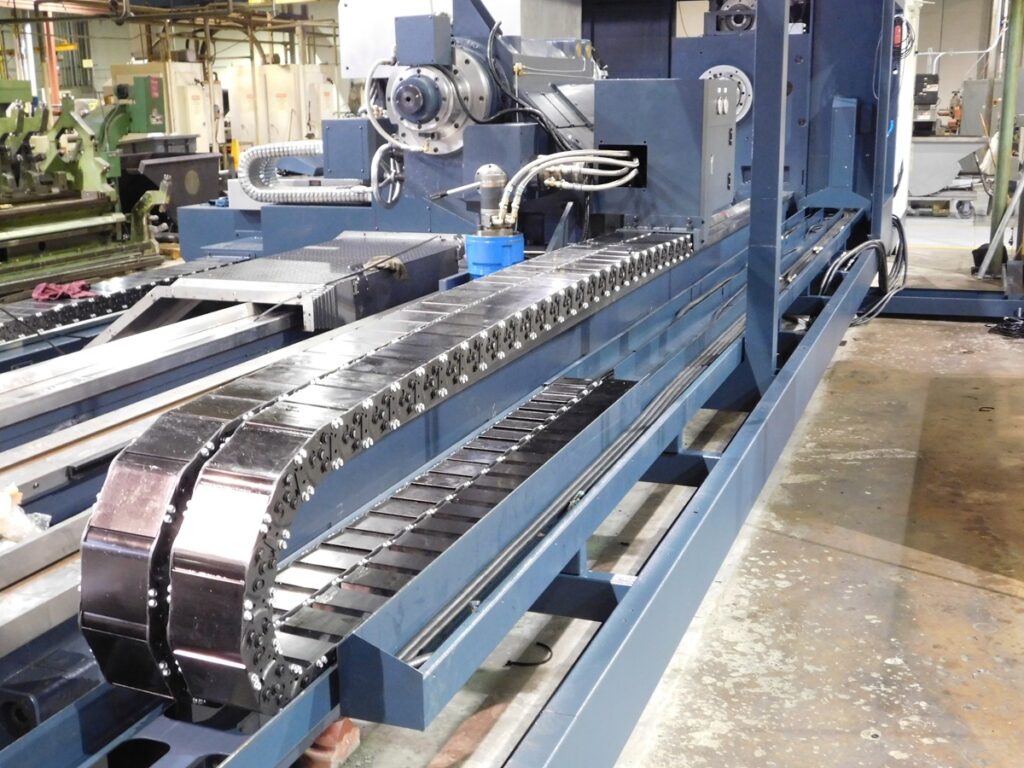

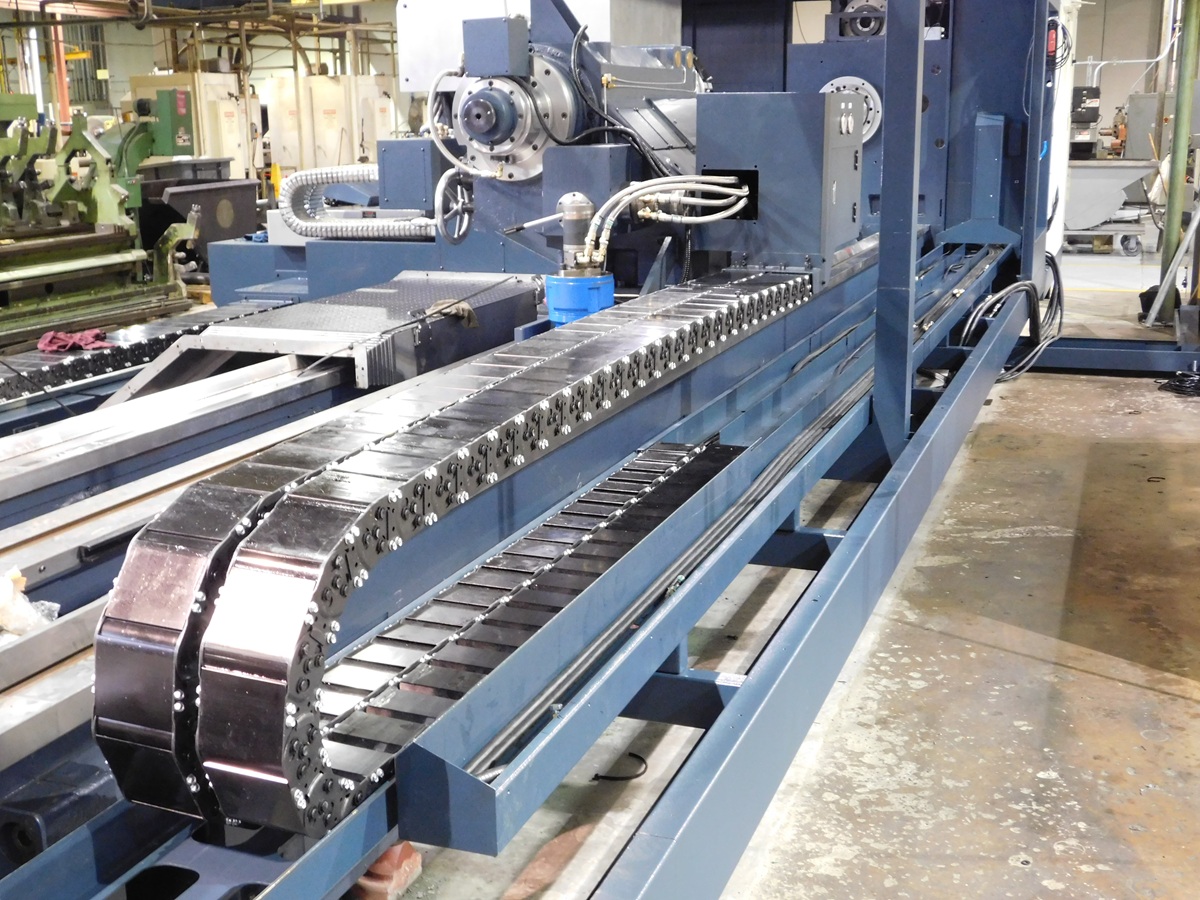

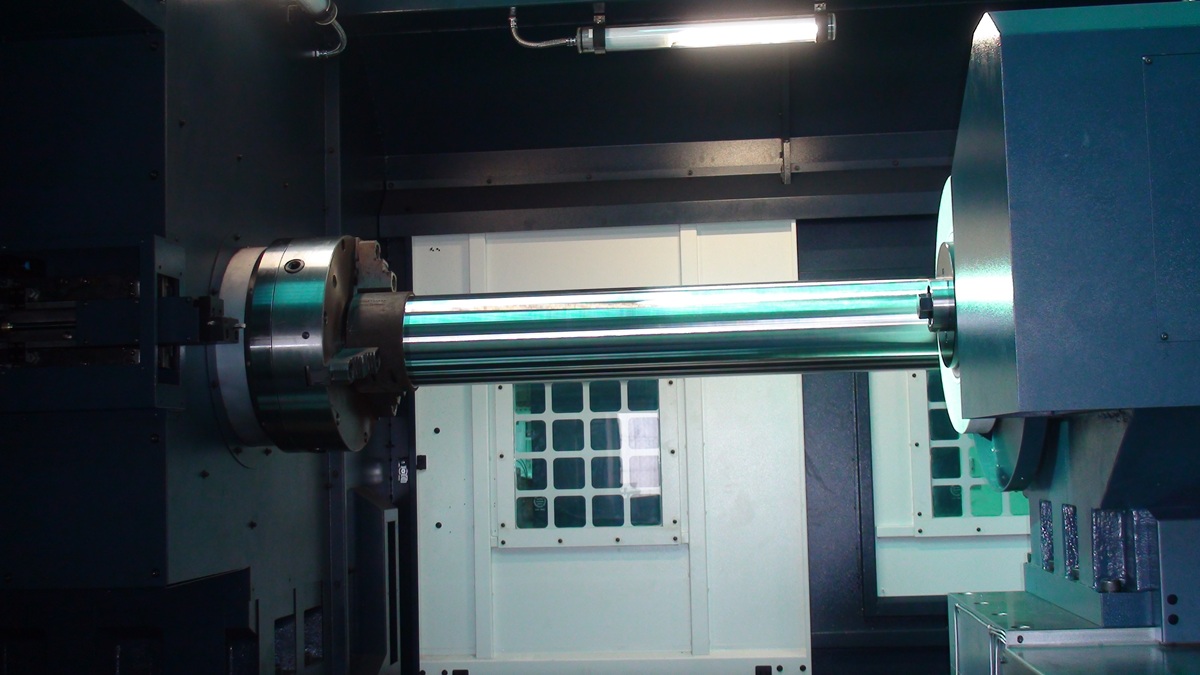

Vibration-Free Long-Axis Travel

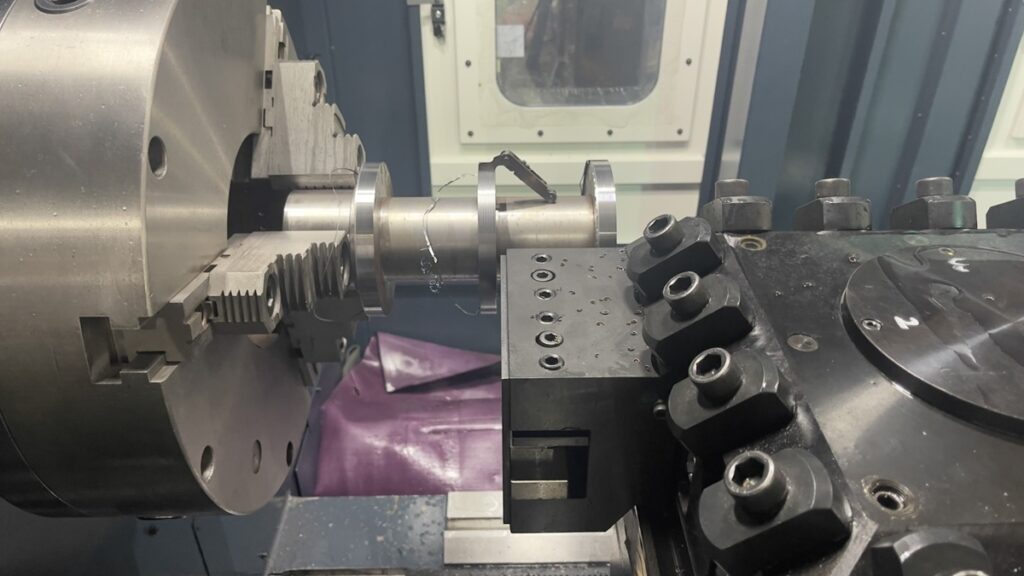

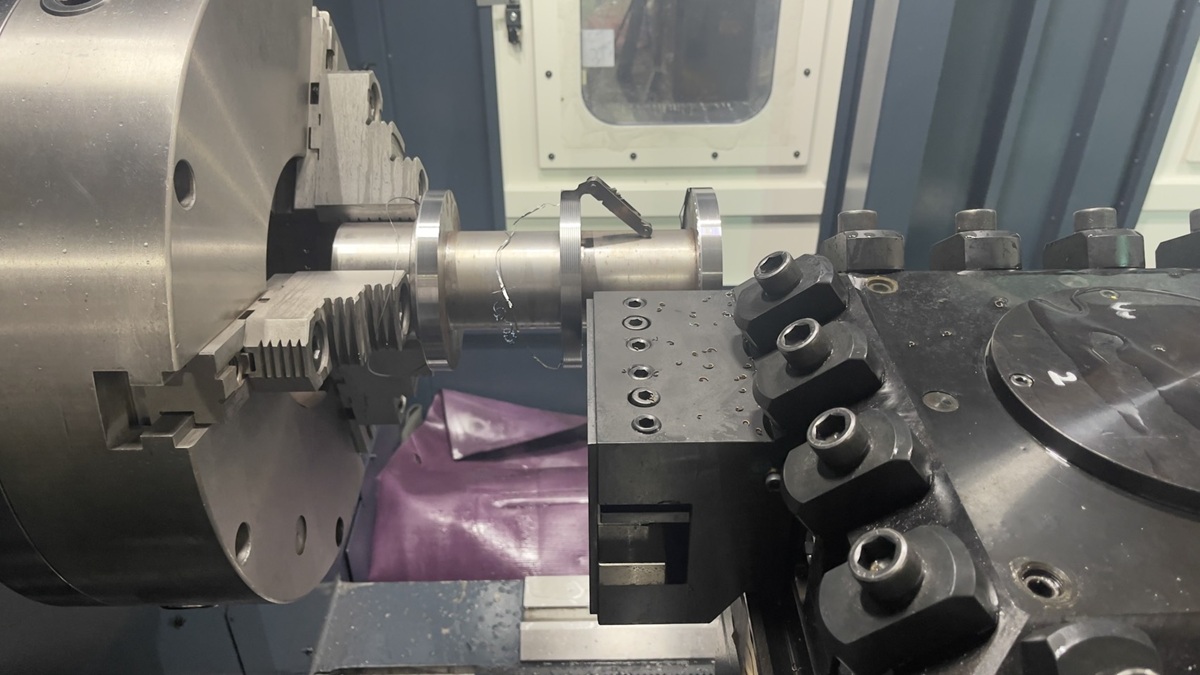

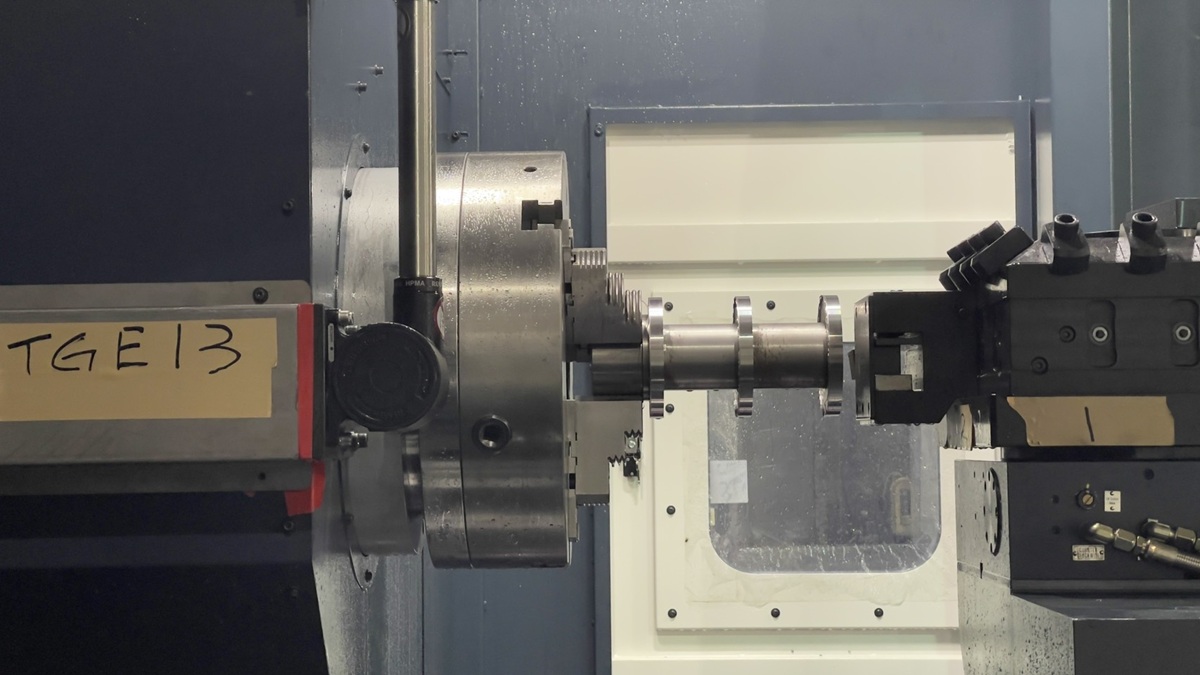

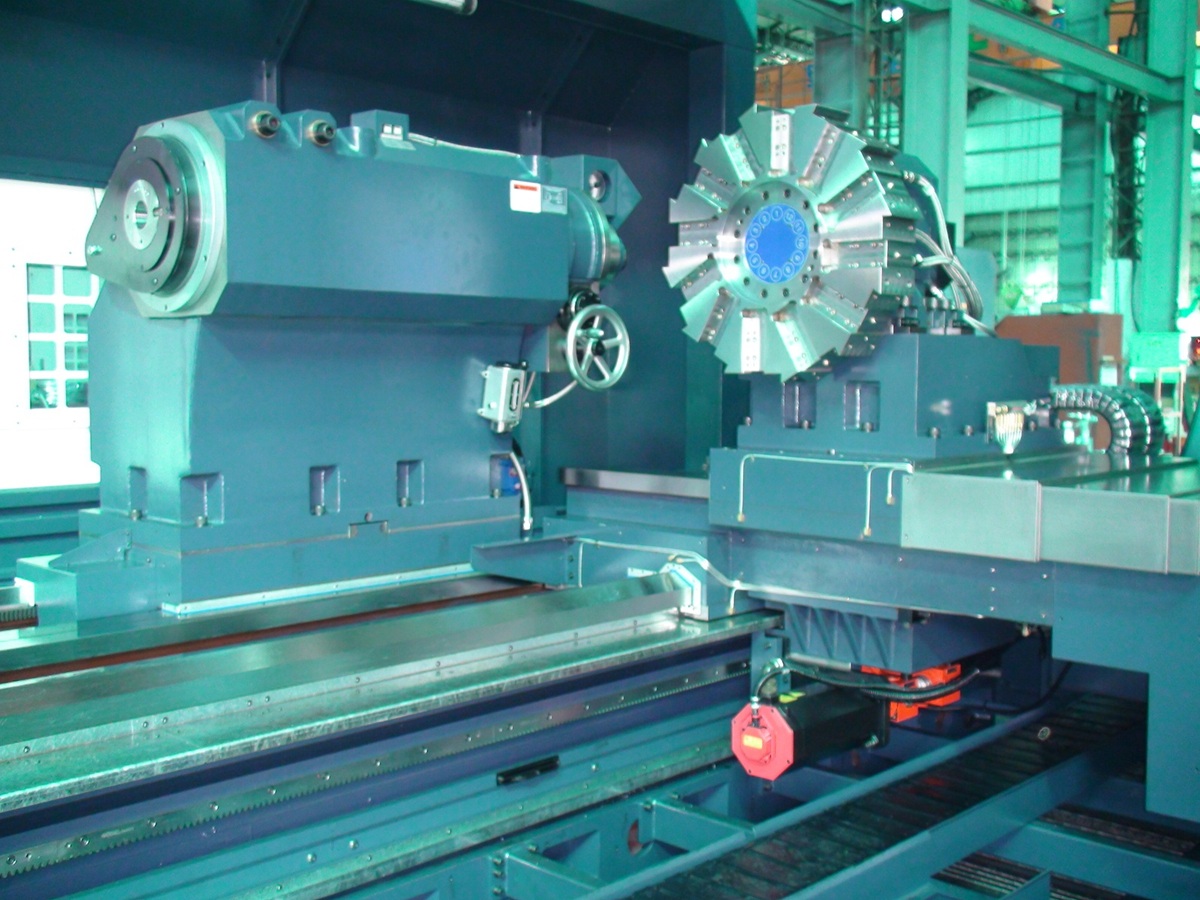

Flexible Tooling and Turret Options

Optional C-Axis and Y-Axis Capability

Precision Tailstock and Part Support

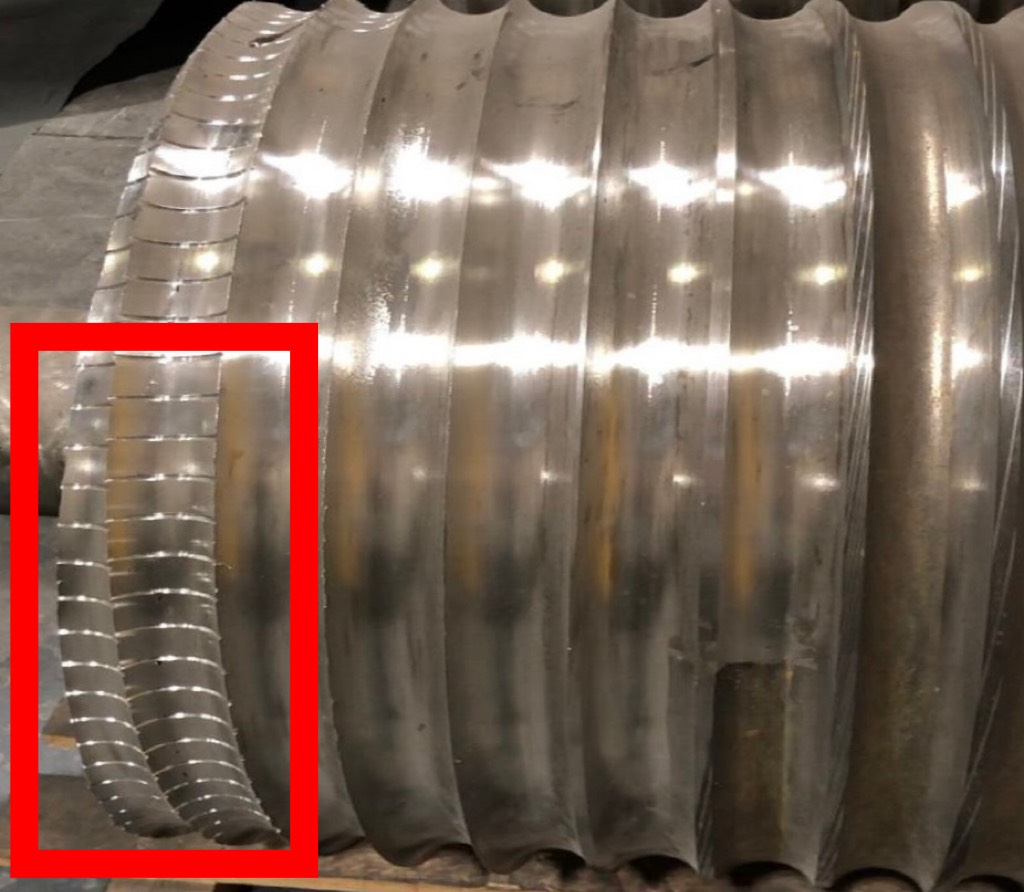

Built for Oversized Workpiece Machining

From massive rotor shafts to aerospace landing gear components, the Johnford LC Series excels in long-part CNC turning applications that demand consistent accuracy, rigidity, and torque. Whether you need CNC lathes for large parts, flat bed turning centers, or heavy-duty shaft lathes, the LC Series delivers the performance needed to stay competitive.

Common Applications

Custom Configurations Available

Each Johnford LC machine can be configured to your specific production needs with:

Need to machine extremely long parts with tight tolerances?

Contact Absolute Machine Tools today to learn how the Johnford LC Series can elevate your long-part turning operations.

Specifications

| Item / Model |

LC-50

Request a Quote |

LC-60

Request a Quote |

LC-70

Request a Quote |

LC-80

Request a Quote |

LC-90

Request a Quote |

|---|---|---|---|---|---|

|

Swing Over Bed (in.) |

50 |

60 |

70 |

80 |

90 |

|

Swing Over Cross Slide (in.) |

35.8 |

43.3 |

51.9 |

62.2 |

72.4 |

|

Center Distance in 1M Increments |

80 – 788 |

80 – 788 |

80 – 788 |

80 – 788 |

80 – 788 |

|

Bed Width (in.) |

48 4-Ways |

48 4-Ways |

48 4-Ways |

48 4-Ways |

48 4-Ways |

|

Spindle Types |

C, D, E, F, G, H, I, J, K |

C, D, E, F, G, H, I, J, K |

C, D, E, F, G, H, I, J, K |

C, D, E, F, G, H, I, J, K |

C, D, E, F, G, H, I, J, K |

|

Turret Tools (Std.) |

12 Vertical |

12 Vertical |

12 Vertical |

12 Vertical |

12 Vertical |

|

Turret Tools (Opt.) |

4 or 6 Horizontal, 8 Vertical, or Twin Turrets |

4 or 6 Horizontal, 8 Vertical, or Twin Turrets |

4 or 6 Horizontal, 8 Vertical, or Twin Turrets |

4 or 6 Horizontal, 8 Vertical, or Twin Turrets |

4 or 6 Horizontal, 8 Vertical, or Twin Turrets |

|

Spindle HP |

50 / 60 / 100 / 133 |

50 / 60 / 100 / 133 |

50 / 60 / 100 / 133 |

50 / 60 / 100 / 133 |

50 / 60 / 100 / 133 |

|

Spindle Drive |

4 Speed Gearbox |

4 Speed Gearbox |

4 Speed Gearbox |

4 Speed Gearbox |

4 Speed Gearbox |

|

C Axis |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Y Axis |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Weight (lbs.) |

Starting at 50,600 |

Starting at 52,800 |

Starting at 55,000 |

Starting at 57,200 |

Starting at 59,400 |

Standard accessories may vary per model/type:

Optional equipment may vary per model/type:

|

Spindle |

Spindle ID |

Draw Tube ID |

RPM (Max) |

Bearing ID |

Chuck Size |

|---|---|---|---|---|---|

|

B(A2-11) |

5.2” |

4.56” |

2000 |

7.1” |

15” ~ 24” hyd. |

|

C (A2-15) |

5.98” |

5.47” |

1500 |

7.87” |

20”~40” hyd. |

|

D (A2-15) |

7.28” |

4.56” |

1000 |

9.45” |

20”~40” hyd. |

|

E (A2-15) |

9.29” |

5.47” |

800 |

11.02” |

24”~48” hyd. |

|

F (A2-20) |

10” |

6.5” |

500 |

12.5” |

24”~48” hyd. |

|

G (A2-20) |

12.5” |

8” |

500 |

14” |

24”~48” hyd. |

|

H (A2-20 |

14” |

—- |

400 |

16” |

28”~60″ man |

|

I (A2-28 |

16” |

—- |

350 |

18.5” |

32”~60” man. |

|

J (A2-28) |

21” |

—- |

250 |

24” |

32”~60” man. |

|

K(A2-32) |

24” |

—- |

200 |

27” |

36”~60” man. |