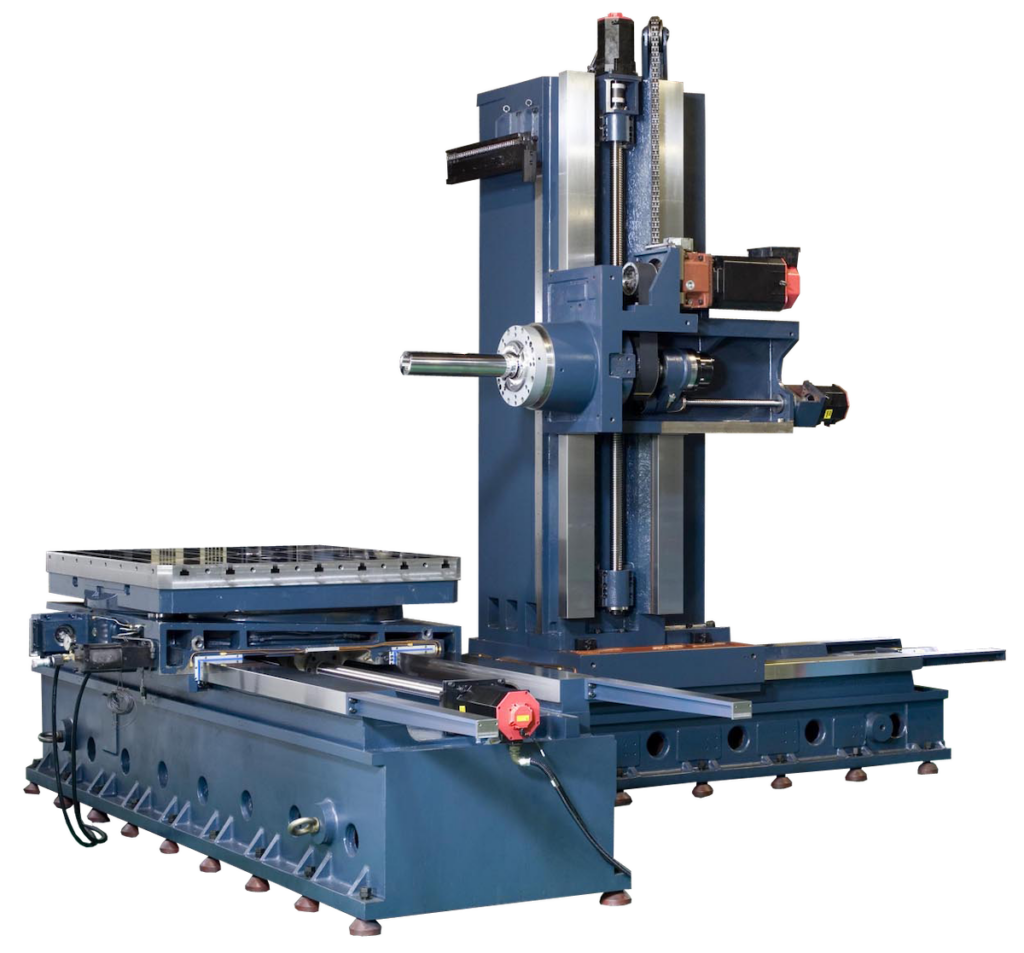

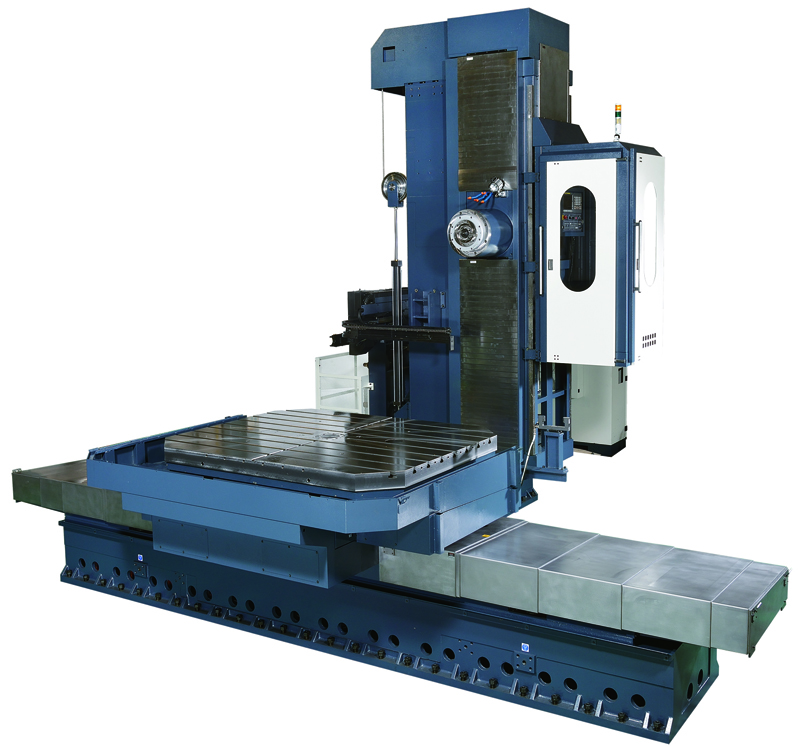

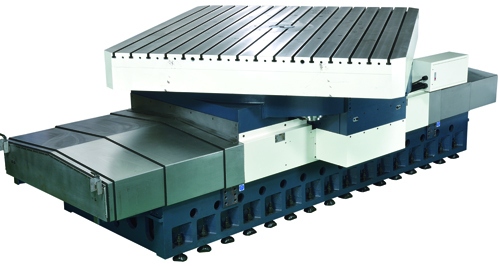

Johnford AHC-1600 Moving-Column Moving-Table Horizontal Machining Center

Built for Power, Precision, and Performance

The Johnford AHC-1600 is a robust moving-column, table-type horizontal machining center designed to handle large, heavy parts with exceptional accuracy and rigidity. Engineered for demanding industries like aerospace, the AHC-1600 combines high-torque cutting capabilities with intelligent design features to ensure maximum stability and performance.

Rigid Construction for High-Load Machining

The AHC-1600 features a moving column for the Z axis and a fully supported moving table for the X axis — eliminating overhang and the need for outriggers or external supports, even under heavy table loads. The rigid Meehanite cast iron frame weighs over 40,000 lbs with standard accessories, providing the mass and damping necessary for precision machining.

- X Axis (Table Travel): Fully supported along the entire length

- Z Axis (Column Travel): Moving column ensures dynamic stability

- No table overhang: Ideal for heavy workpieces and high-accuracy cuts

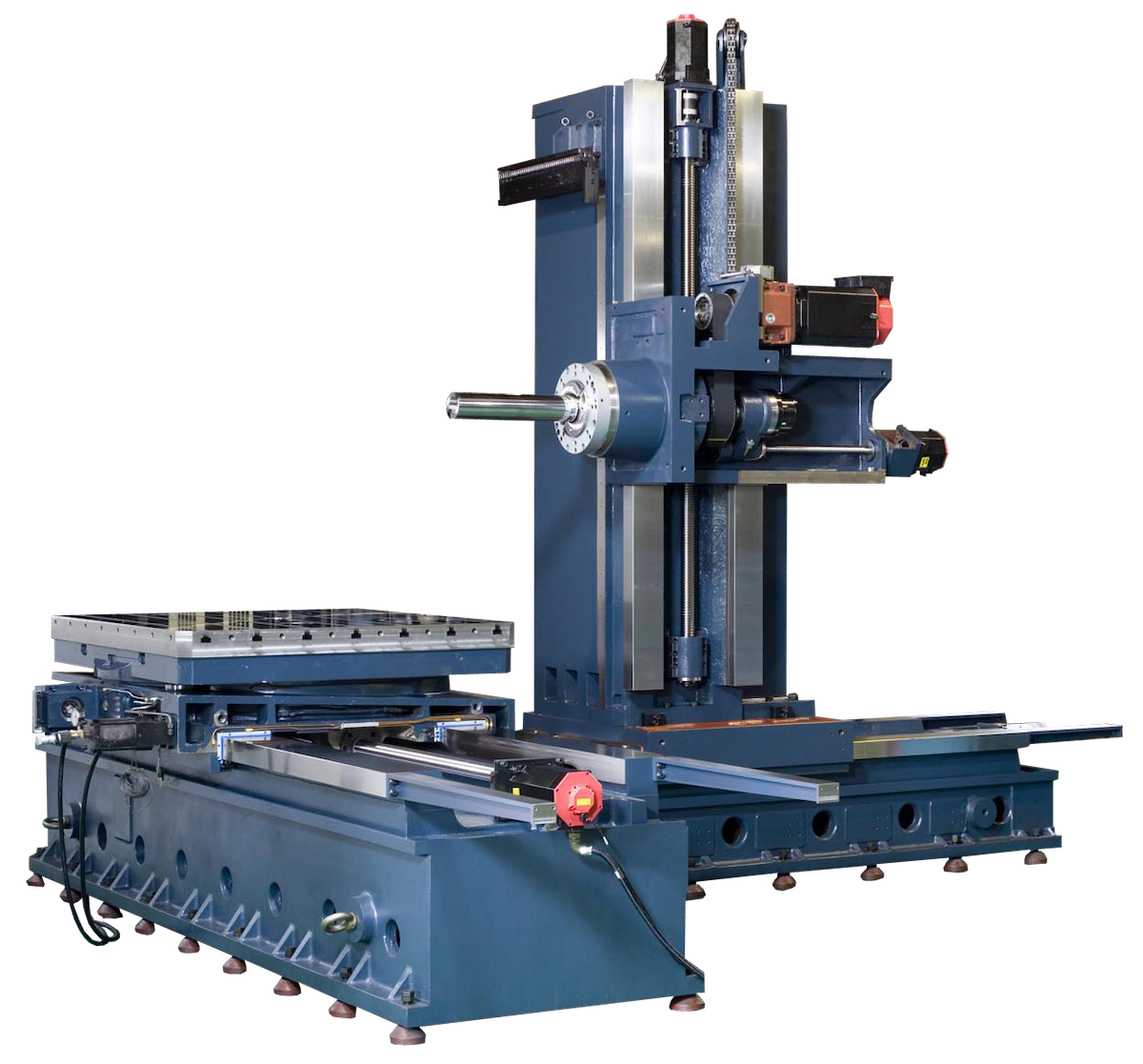

Box Way Construction for Durability and Accuracy

All three axes — X, Y, and Z — ride on precision-ground, induction-hardened box ways, ensuring long-term rigidity and vibration resistance. Mating surfaces are coated with Turcite-B and hand-scraped for precision fit, while a pressurized automatic lubrication system maintains smooth operation.

- Box Ways in X, Y, Z axes

- 50 mm pre-tensioned ballscrews with powerful servo motors

- Heidenhain linear scales (standard) ensure high accuracy on all linear axes

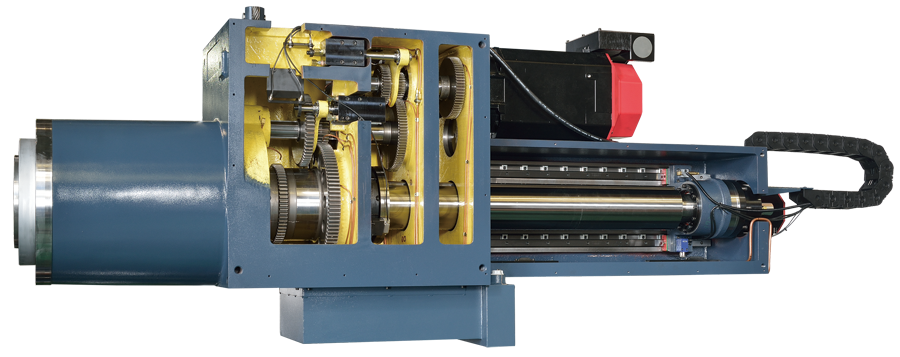

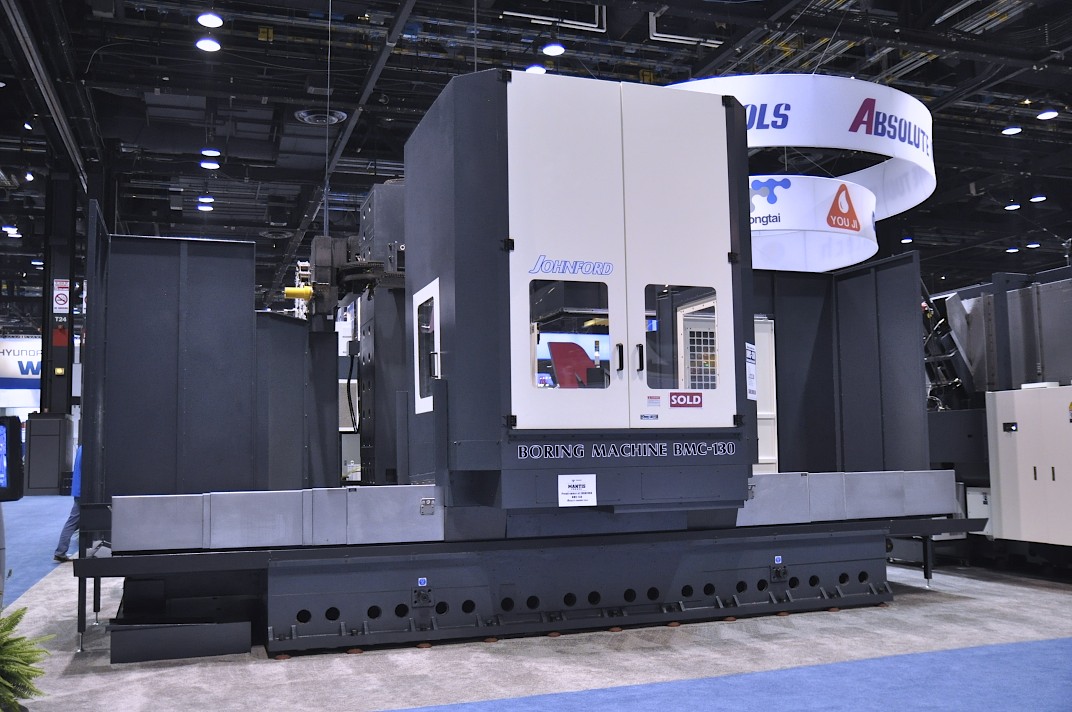

Powerful Spindle Options to Match Any Application

The standard 6,000 rpm, 50-taper spindle with 35 HP and a 2-speed gear drive offers strong torque and excellent chip removal. The spindle and gearbox are oil-cooled to minimize thermal distortion. Optional spindle configurations meet a wide range of machining needs:

- 10,000 rpm 50-taper direct drive spindle (optional)

- 15,000 rpm HSK-100A spindle with 56 HP and 300 lb-ft torque (optional)

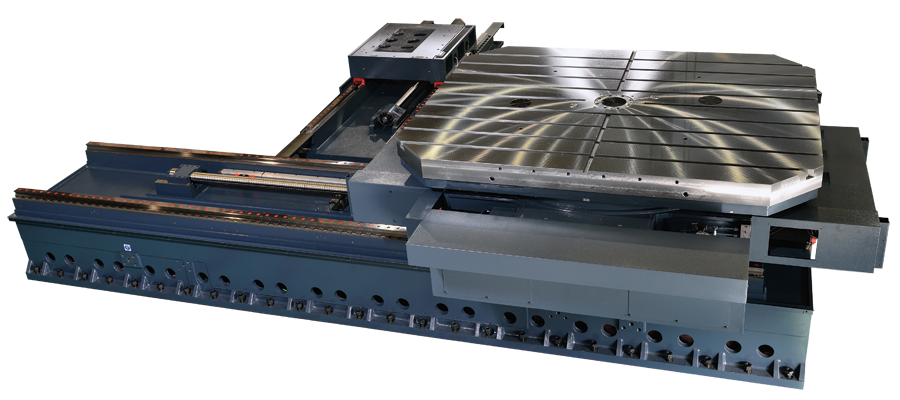

Tool and Workpiece Flexibility

The AHC-1600 is equipped with a heavy-duty 40-tool arm-type automatic tool changer (ATC) standard, with 60-, 80-, and 120-tool options available. It also features a combination flat table and full B-axis rotary table for complex multi-face machining.

- 63″ x 32″ table with integrated 800 mm rotary table

- 4+1 machining standard; full 5-axis contouring optional

- Comprehensive chip and coolant systems standard

- Full machine enclosure included for safety and cleanliness

Control Options for Any Level of Machining

The AHC-1600 comes standard with the Fanuc Oi-MF Plus CNC control, ideal for a wide variety of 3- and 4-axis applications. For more advanced work, the optional Fanuc 31i-MB control enables high-speed processing and full 5-axis simultaneous contouring.

Specifications

| Item / Model |

AHC-1600

Request a Quote

|

|---|---|

|

X Axis Travel |

63″ |

|

Y Axis Travel |

50″ |

|

Z Axis Travel |

40″ |

|

Spindle Center to Tabletop |

5.5″ – 55.5″ |

|

Spindle Nose to Table Center |

7.9″ Min. / 47.9″ Max. |

|

Table Size |

63″ x 32″ (72″/79″/118″ Length opt.) |

|

Max. Workpiece Load |

10,120 lbs. |

|

4th (B) Axis Rotary Table Diameter |

31.5″ |

|

4th (B) Axis Max. Workpiece Load |

4,400 lbs. |

|

Spindle |

35 HP (40 HP opt.) |

|

No. of Tools |

40 (60/80/120 opt.) |

|

Spindle Drive |

2 Speed Gearbox |

|

RPM |

6,000 RPM |

|

ATC Capacity |

40 (60, 80, 120 opt.) |

|

Weight – base only |

44,000 lbs. |