You Ji DSM Series – Duplex Milling Machines

If you’re looking for CNC Duplex Milling Machines, you’re in the right place. These versatile machines can increase production in your shop by up to 50% of other, conventional methods — like individual milling machines. Plus, it does so in reduced space and the upfront investment that comes from two single machines. So, you’ll be saving space while increasing output. These CNC Duplex Milling Machines only require one sole operator, letting your other operators work elsewhere.

With these CNC Duplex Milling Machines, you can have different configurations like a single working area, pendulum working areas or pallet changing system. Whatever’s needed for your shop to operate in the best way.

As trusted machine tool distributors, we only choose the best products to stock our shelves. You’ll find You Ji’s DSM heavy duty duplex or double-sided milling machine series here. And, we offer all of the CNC Duplex Milling Machine parts you’ll need.

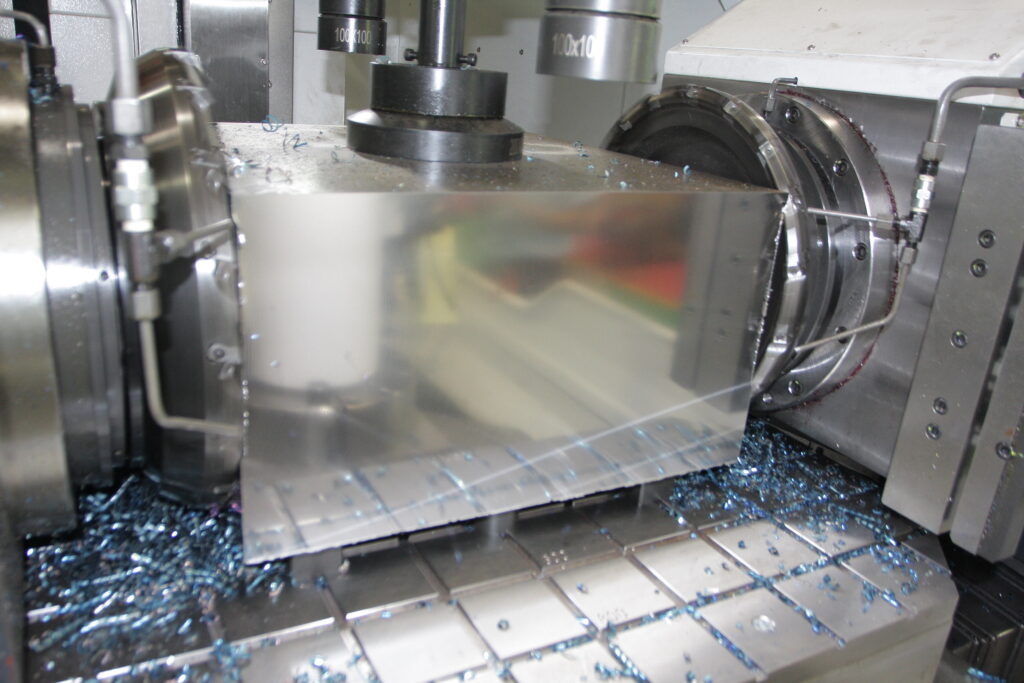

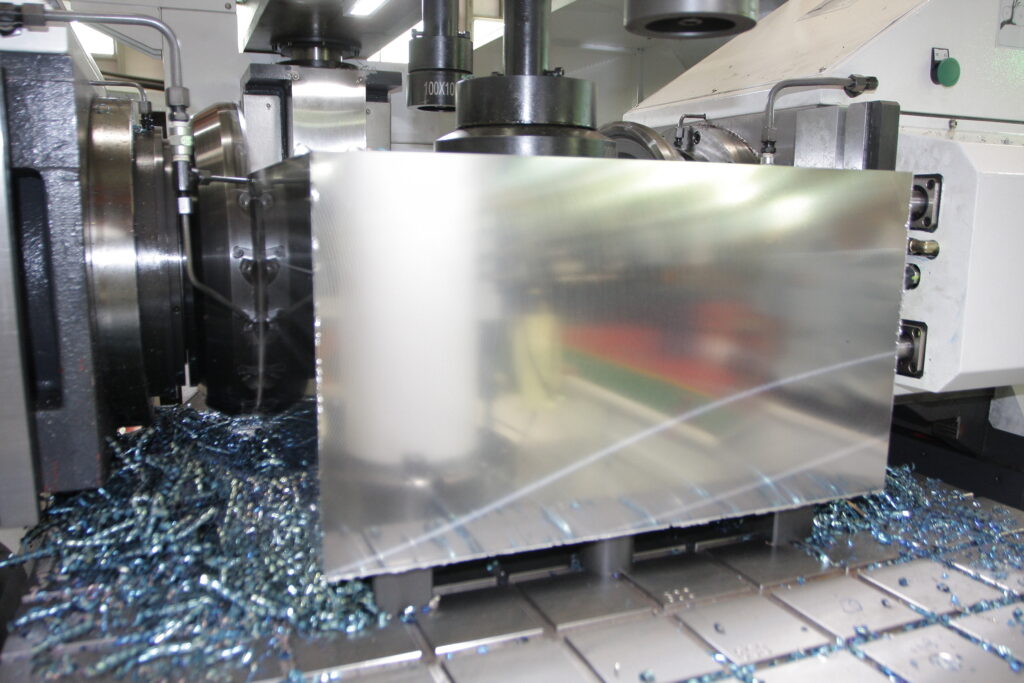

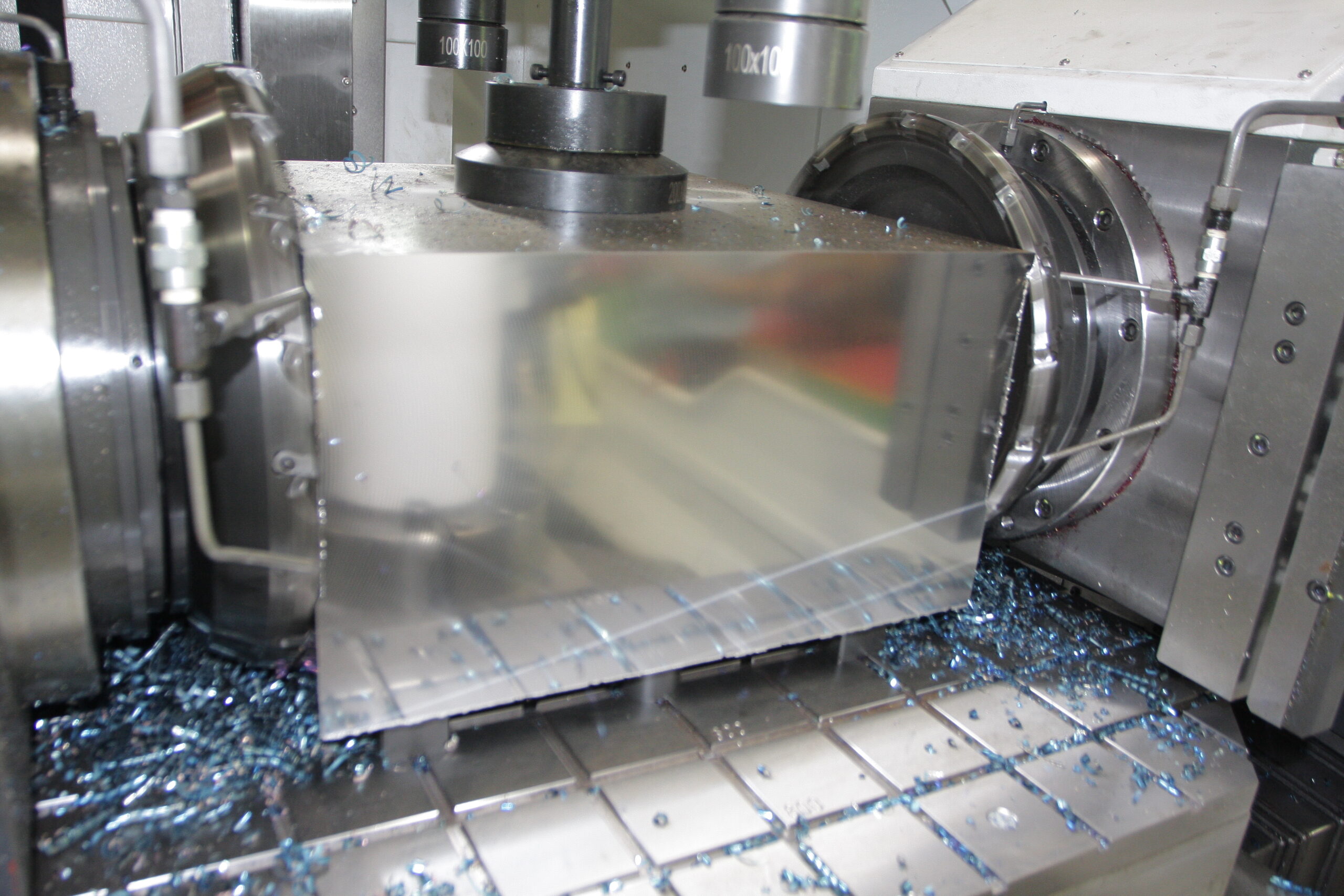

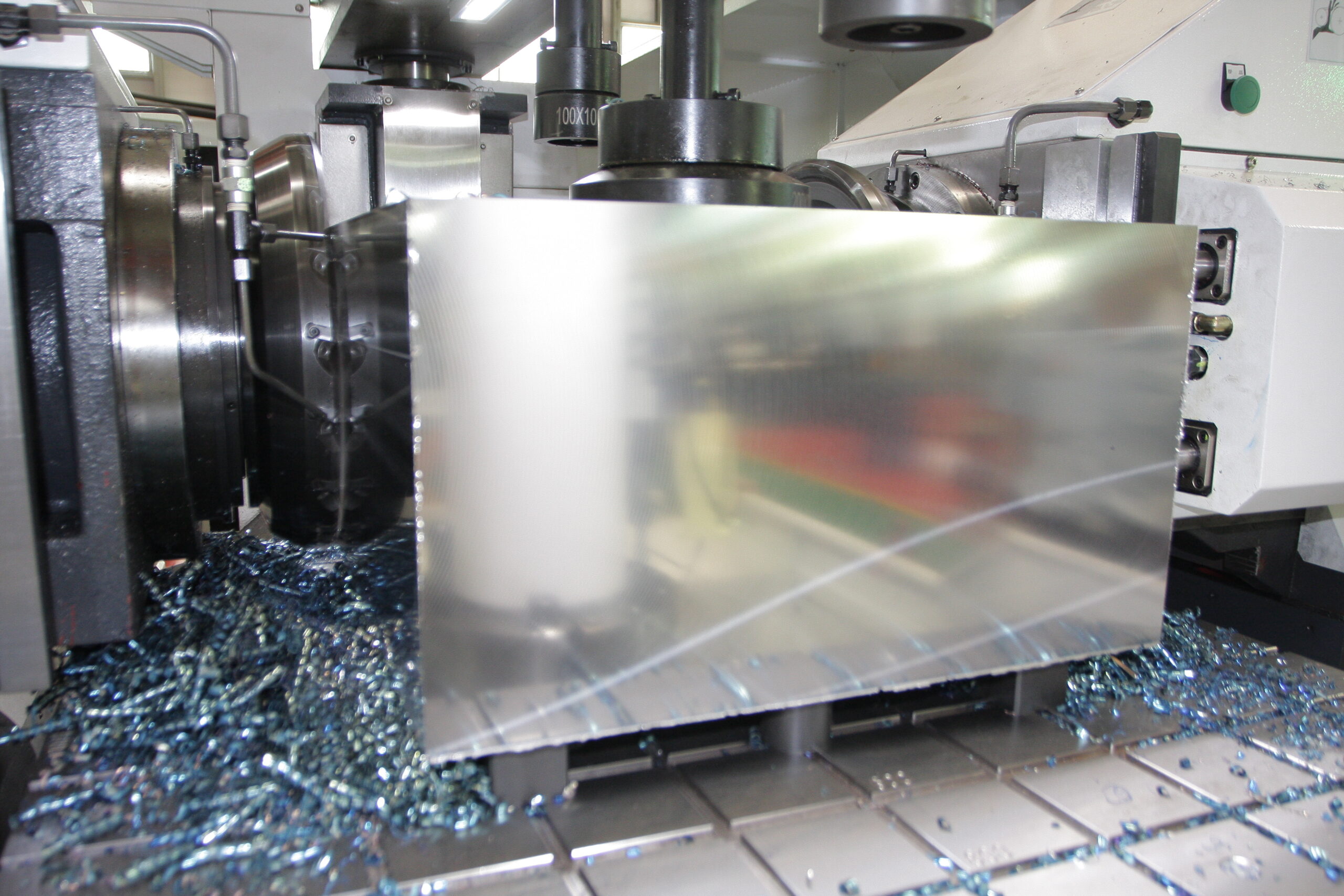

You Ji’s DSM heavy duty duplex or double-sided milling machine series was designed specifically for production squaring and chamfering of square and rectangular blocks. The machines are engineered to perform heavy duty machining with high accuracy and high throughput.

Longitudinal X-axis travels for the five-machine series range from 23.6″ (600 mm) to 72.8″ (1849 mm) and Y and Z axes’ cross-travel extends from 14.7″ (373 mm) to 35.4″ (900 mm). Rotary table sizes start at 20.5″ (520 mm) square and the largest versions are 39.4″ (1000 mm) square.

The machines combine a rigid rotary table with dual milling heads. Each milling head moves independently in the Z-axis on rigid box ways. The rotary table moves in the X-axis on roller type linear ways, indexes every 45°, and clamps via a Hirth coupling to maximize rigidity.

The milling heads feature high-horsepower, large-diameter spindles that produce high torque at low rpm to run large diameter cutters. Each spindle is powered by a 20 hp or 30 hp motor (depending on model) with a variable speed range. Spindle tapers are 50 or 60 taper equivalent.

The machines operate semi-automatically. After the workpiece is shuttled into the machine manually, the part is automatically centered and clamped to the rotary table via hydraulic cylinders that apply pressure to the workpiece in 3 steps, from light pressure while centering the part to high-pressure maximum clamping force. Quick change, modular upper and lower fixtures hold the workpiece in place. The machine comes with 10 sets of clamping fixtures in a variety of sizes and shapes tailored to the user’s work.

A workpiece probe verifies the raw material size and can also provide rapid first part inspection.

The Mitsubishi C-70 controller, with touch screen interface and a You Ji custom HMI (Human – Machine Interface), makes machine set-up and operation quick and easy and enables setup of the next job while machining is in process.

So, if you’re looking for a way to increase production in your shop without breaking the bank or taking up too much space, CNC duplex milling machines may be just what you need. If you don’t see what you need, we can still help. Tell us about your project or problem and we’ll be sure to assist in the best way possible.

Absolute Machine Tools has invested more than $20 million dollars in spare parts and miscellaneous inventories for CNC machines. Our goal is to reduce downtime and get our customers back in good running order as soon as possible. If you have any questions, please contact us, you can call us at 800-852-7825 or find us here.

Specifications

| Item / Model |

DSM-480

Request a Quote |

DSM-630

Request a Quote |

DSM-800

Request a Quote |

DSM-1000

Request a Quote |

DSM-1200

Request a Quote |

|---|---|---|---|---|---|

|

Travels / Capacity | |||||

|

Longitudinal Travel X-Axis |

23.6″ |

43.3″ |

51.1″ |

61″ |

72.8″ |

|

Cross Travel Head 2 Z-Axis |

14.17″ |

19.7″ |

23.6″ |

27.5″ |

35.4″ |

|

Spindle Nose to Table Center |

2.67″ – 16.65″ |

2.87″ – 22.56″ |

2.68″ – 26.3″ |

4.72″ – 36.2″ |

3.07″ – 38.5″ |

|

Spindle Center to Table Top |

4.13″ |

7.87″ |

7.87″ |

9.8″ |

9.8″ |

|

Distance Between Spindle Noses |

5.35″ – 33.3″ |

5.74″ – 45.1″ |

5.35″ – 52.6″ |

9.4″ – 72.4″ |

6.1″ – 77″ |

|

Workpiece Size Range |

.75″ x .75″ – |

1.57″ X 1.57″ – |

1.57″ x 1.57″ – |

4.72 x 4.72 – |

12.6″ X 12.6″ – |

|

Max Workpiece Thickness |

5.9″ (10″ Cutters) |

9.1″ (10″ Cutters) |

11.8″ (12.4″ Cutters) |

15.7″ (16.5″ Cutters) |

15.7″ (16.5″ Cutters) |

|

Cutter Size |

10″ |

10″ |

12.4″ |

16.5″ |

16.5″ |

|

Table / Rotary Table | |||||

|

Table Diameter |

20.5″ x 20.5″ |

20.5″ X 20.5″ |

25.6″ x 25.6″ |

33.5″ x 33.5″ |

39.4″ x 39.4″ |

|

Max Workload on Table |

2,640 lbs. |

2,640 lbs. |

5,500 lbs. |

5,500 lbs. |

1,019 ft. lbs. |

|

Rotary Table Minimum Index Angle |

45° (8 Indexes) |

45° (8 Indexes) |

45° (8 Indexes) |

45° (8 Indexes) |

45° (8 Indexes) |

|

Spindle (Standard) | |||||

|

Spindle Motor Power |

20 HP x 2 |

20 HP x 2 |

20 HP x 2 |

30 HP x 2 |

30 HP x 2 |

|

Spindle Torque |

140 ft. lbs. |

583 ft. lbs. |

583 ft. lbs. |

1,109 ft. lbs. |

1,109 ft. lbs. |

|

Spindle Taper |

NT-50 |

NT-50 |

NT-60 |

NT-60 |

NT-60 |

|

Spindle Drive System |

Belt Drive |

Belt Drive |

Belt Drive |

Belt Drive |

Belt Drive |

|

Spindle Speed |

170 – 1,000 RPM |

132 – 250 RPM |

132 – 250 RPM |

75 – 101 RPM |

75 – 101 RPM |

|

Ballscrews and Axis Motors | |||||

|

X-Y-Z Ballscrew Diameter |

1.57″ – 1.57″ – 1.57″ |

2″ – 1.57″ – 1.57″ |

2″ – 1.57″ – 1.57″ |

2″ – 1.57″ – 1.57″ |

2″ – 1.57″ – 1.57″ |

|

Ballscrew Type |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

Class 3 Double Nut |

|

Ballscrew Mounting Type |

Pre-tensioned |

Pre-tensioned |

Pre-tensioned |

Pre-tensioned |

Pre-tensioned |

|

X-Y-Z Servo Motor HP |

4.6 – 2.0 – 2.0 HP |

5.2 – 5.2 – 5.2 HP |

5.2 – 5.2 – 5.2 HP |

9.0 – 6.0 – 6.0 HP |

9.0 – 6.0 – 6.0 HP |

|

Servo Motor Mounting |

Direct Coupled XYZ |

Direct Coupled XYZ |

Direct Coupled XYZ |

Direct Coupled XYZ |

Direct Coupled XYZ |

|

Feeds | |||||

|

Rapid Traverse Rate X, Y, Z |

590, 394, 394 IPM |

590, 394, 394 IPM |

590, 394, 394 IPM |

590, 394, 394 IPM |

590, 394, 394 IPM |

|

Manual Cutting Feed Rate |

.04 – 59.1 IPM |

.04 – 59.1 IPM |

.04 – 59.1 IPM |

.04 – 59.1 IPM |

.04 – 59.1 IPM |

|

Positioning Accuracy |

± .0003″ |

± .0003″ |

± .0003″ |

± .0003″ |

± .0003″ |

|

Repeatability |

.0002″ |

.0002″ |

.0002″ |

.0002″ |

.0002″ |

|

Rotary Table Index Speed (90°) |

2 Seconds |

2 Seconds |

2 Seconds |

2 Seconds |

2 Seconds |

|

Rotary Table Positioning Accuracy/Repeatability (arc seconds) |

6 Arc Seconds / 3 Arc Seconds |

6 Arc Seconds / 3 Arc Seconds |

6 Arc Seconds / 3 Arc Seconds |

8 Arc Seconds / 3 Arc Seconds |

8 Arc Seconds / 3 Arc Seconds |

|

General | |||||

|

Coolant Tank Capacity |

100 Gallons |

100 Gallons |

100 Gallons |

100 Gallons |

130 Gallons |

|

Machine Weight |

22,000 lbs. (est.) |

24,200 lbs. (est.) |

28,600 lbs. (est.) |

46,200 lbs. (est.) |

55,000 lbs. (est.) |

|

Floor Space |

134″ x 127″ x 92″ |

161″ x 150″ x 116″ |

196″ x 169″ x 118″ |

225″ x 197″ x 126″ |

252″ x 225″ x 126″ |

|

Machine Power Source* |

220V, 3 Phase, 150 Amps |

220V, 3 Phase, 150 Amps |

220V, 3 Phase, 150 Amps |

220V, 3 Phase, 200 Amps |

220V, 3 Phase, 200 Amps |

|

Air Source |

90 PSI |

90 PSI |

90 PSI |

90 PSI |

90 PSI |