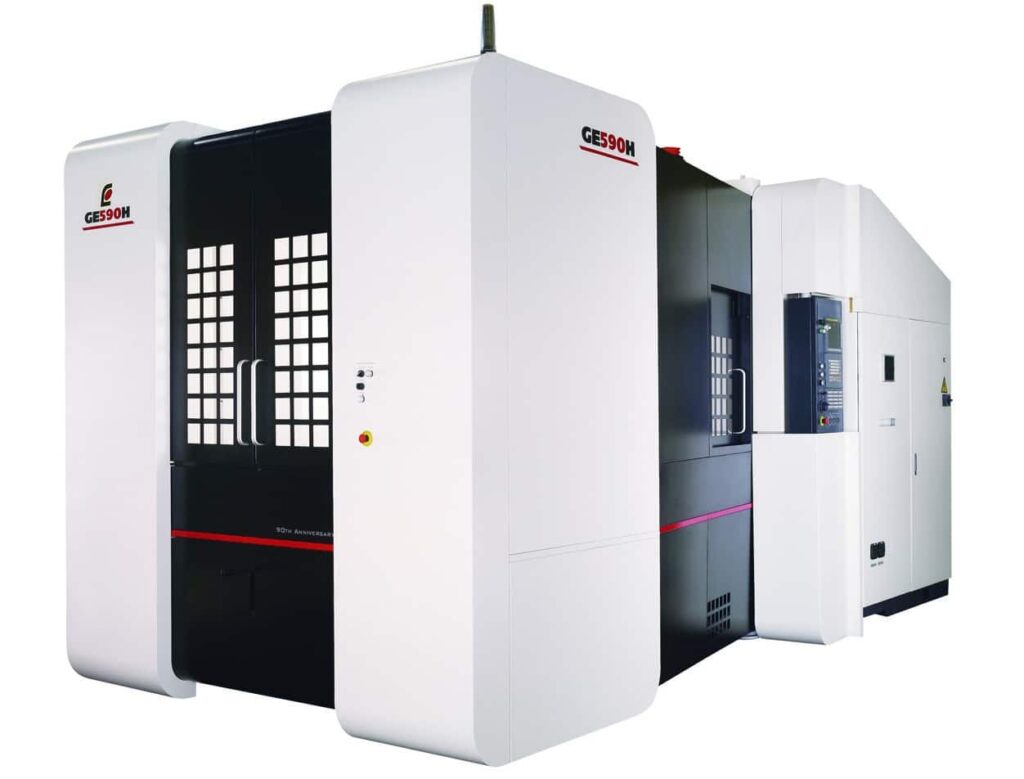

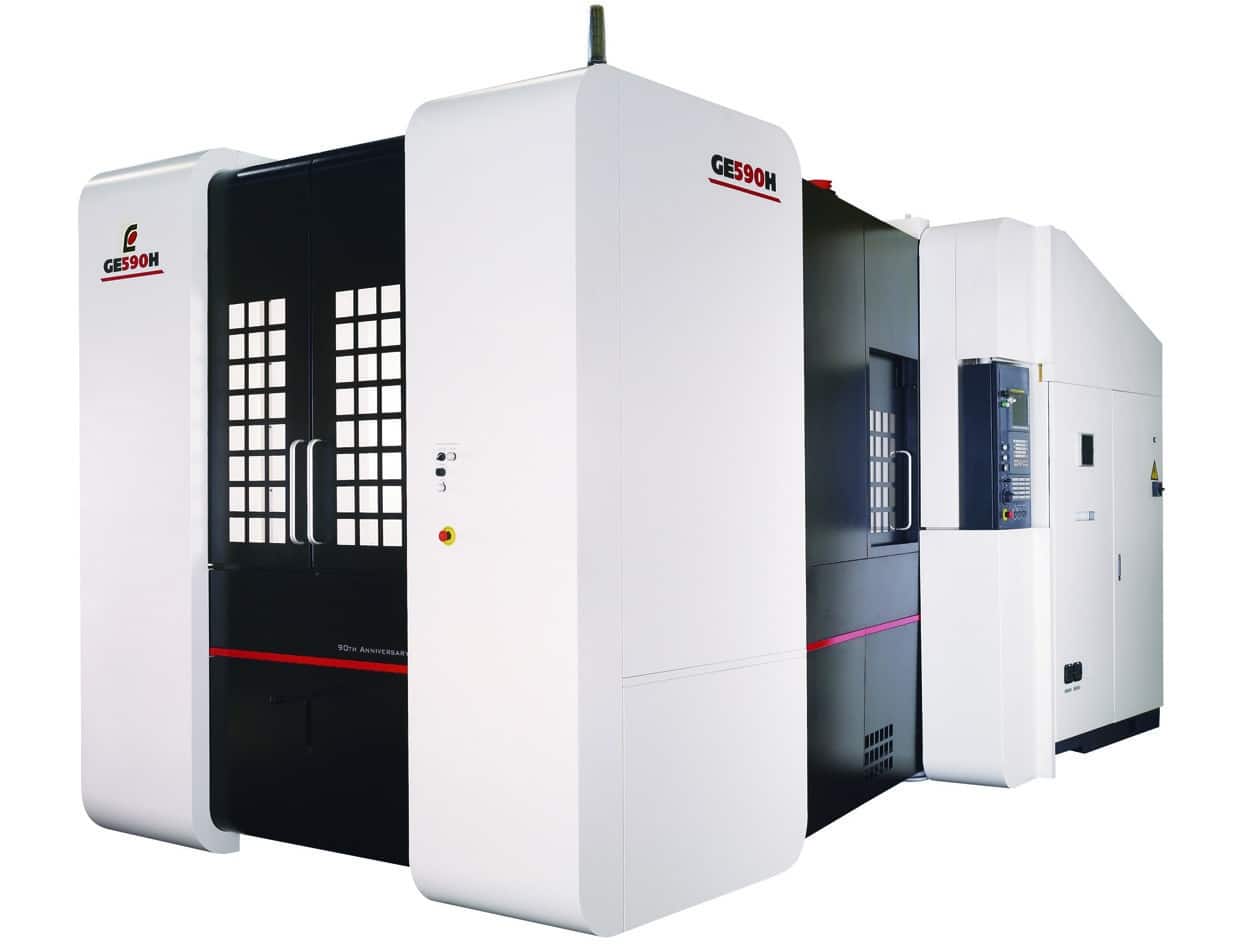

Enshu GE Series – Horizontal Machining Centers

Blazing Speed of 3,543 IPM Rapids on All 3 Axes

High-speed, high-precision CNC horizontals built for production efficiency and accuracy.

The Enshu GE Series is engineered to support metal cutting manufacturers that demand repeatability, speed, and uptime. These high-performance horizontal machining centers feature traveling column designs, rotary automatic pallet changers, and a range of spindle options suited for both light-duty aluminum and heavy-duty steel or alloy applications. With pallet sizes ranging from 400mm to 630mm and a choice of CAT-40 or CAT-50 taper spindles, the GE Series offers exceptional flexibility for a wide variety of production environments.

Designed for aggressive metal removal, fast tool changes, and continuous operation, the GE Series is ideal for manufacturers in aerospace, automotive, and general machining industries who want a horizontal platform that improves throughput while maintaining consistent precision across every shift.

Key Features

- Rapid Axis Motion

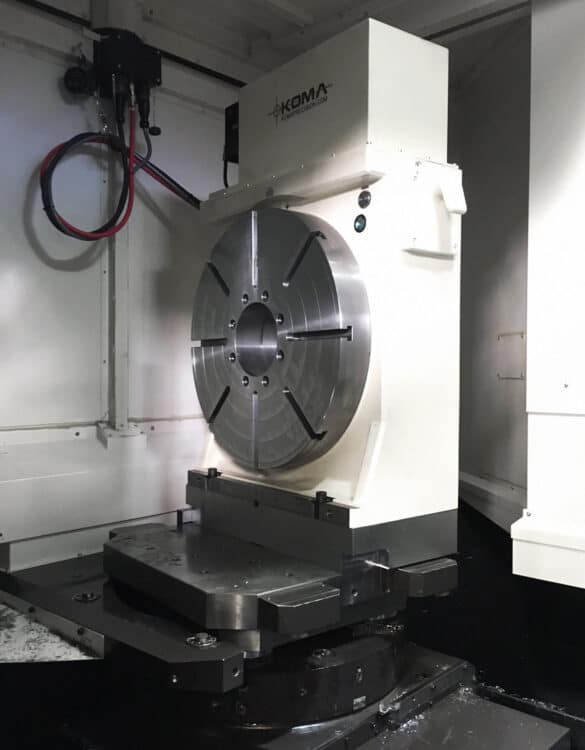

Up to 3,543 IPM (90 m/min) on the X, Y, and Z axes for GE460H and GE480H models, reducing non-cut time and maximizing throughput. - Rotary Automatic Pallet Changer (APC)

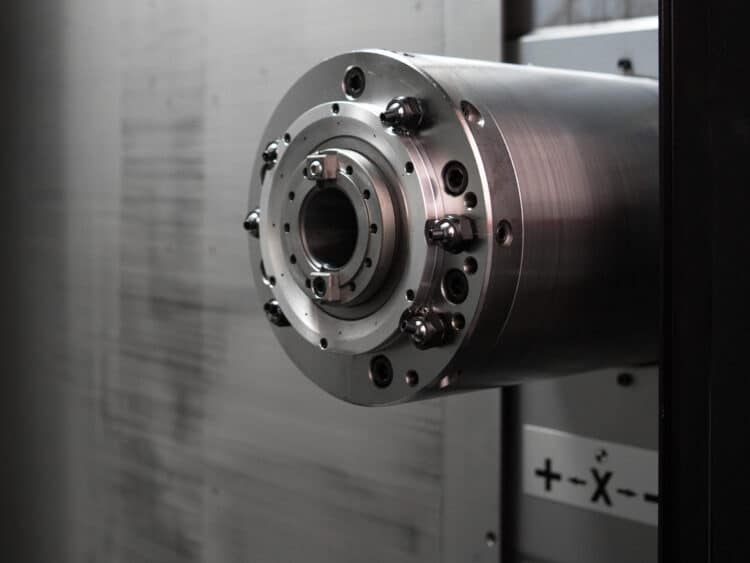

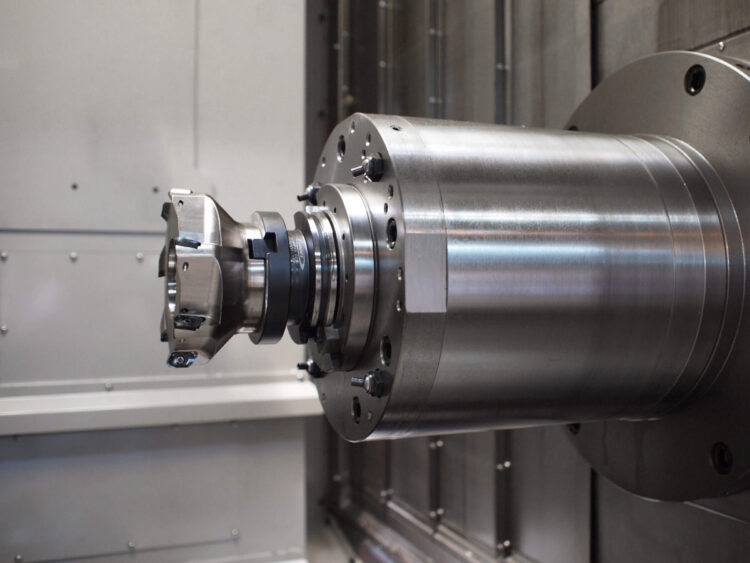

Standard on all GE Series machines: 7 seconds for 400mm models, 10 seconds for 500mm, and 15 seconds for 630mm. Smooth and reliable operation ensures continuous production with minimal manual handling. - High-Power Spindles

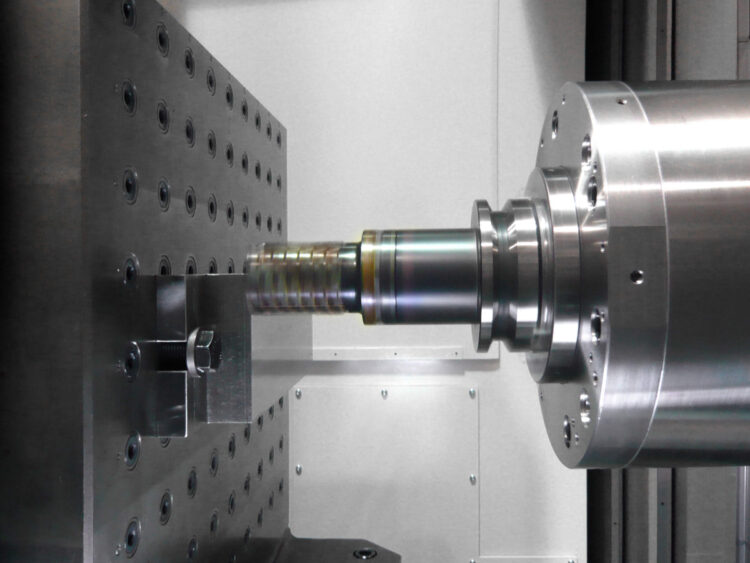

CAT-40 Big Plus (50 HP / 15,000 RPM) or CAT-50 Big Plus (60 HP / 10,000 RPM) options allow you to tailor cutting power and torque to your application. Integral motors with thermal control deliver consistent performance under load. - Thermal Stability and Accuracy

Refrigerated ballscrews, temperature-controlled spindles, and motor mounts maintain dimensional accuracy across long production runs and fluctuating ambient temperatures. - Full B-Axis Indexing

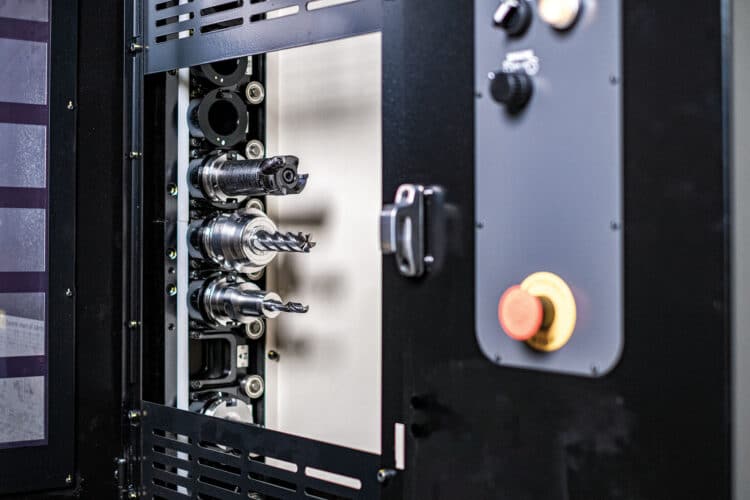

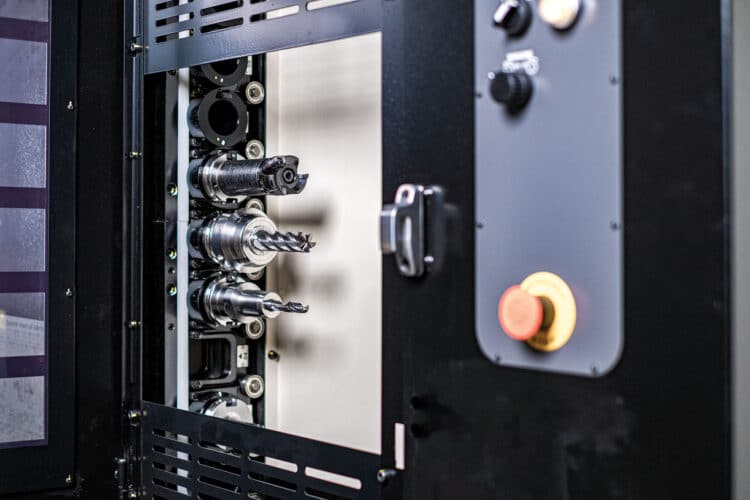

Precision indexing to 0.001° provides multi-face machining capability, eliminating secondary setups and improving overall part accuracy. - Flexible Tooling Options

Tool magazines from 60 tools standard up to 396-tool matrix options are available, with tool-to-tool change times as low as 1.2 seconds depending on configuration. - Automation Integration Ready

The GE Series is built to scale — from standalone setups to multi-pallet systems, robot loading, or full flexible manufacturing cells.

With robust cast-iron construction, ultra-fast pallet exchange, and versatile spindle choices, the Enshu GE Series empowers manufacturers to run longer, cut faster, and maintain tighter tolerances without compromise. Backed by Absolute Machine Tools’ engineering support, service team, and automation specialists, the GE Series is a productivity-driven investment for shops that demand reliable output shift after shift.

Specifications

| Item / Model |

GE460H

Request a Quote |

GE480H

Request a Quote |

GE580H

Request a Quote |

GE590H

Request a Quote |

|---|---|---|---|---|

|

X Axis Travel |

23.6″ |

31.5″ |

31.5″ |

39.3″ |

|

Y Axis Travel |

23.6″ |

31.5″ |

31.5″ |

35.4″ |

|

Z Axis ravel |

23.6″ |

31.5″ |

32.7″ |

41.3″ |

|

Rapid Traverse (XYZ) |

3,543 IPM |

3,543IPM |

2,362 IPM |

1,968 IPM |

|

Spindle Taper |

CAT-40 Big Plus |

CAT-40 Big Plus |

CAT-50 Big Plus |

CAT-50 Big Plus |

|

Spindle Power |

50 HP |

50 HP |

60 HP |

60 HP |

|

Spindle Speed |

15,000 RPM |

15,000 RPM |

10,000 RPM |

10,000 RPM |

|

Spindle Drive |

Integral |

Integral |

Integral |

Integral |

|

Guideways |

Linear |

Linear |

Linear |

Linear |

|

Pallet Size |

15.7″ x 15.7″ (400mm) |

19.7″ x 19.7″ (500mm) |

19.7″ x 19.7″ (500mm) |

24.8″ x 24.8″ (630mm) |

|

Pallet Load per Pallet |

1,100 lbs. |

1,100 lbs. |

1,763 lbs. |

2,650 lbs. |

|

Pallet Changer |

Rotary |

Rotary |

Rotary |

Rotary |

|

ATC Capacity (Arm-Type) |

60 (118, 180, 252, 396 Opt.) |

60 (118, 180, 252, 396 Opt.) |

78 (130, 182 Opt.) |

78 (130 Opt.) |

|

ATC Time |

1.2 sec. |

1.2 |

2.1 |

2 |

|

Weight |

25,200 lbs. |

27,000 lbs. |

31,900 lbs. |

51,700 lbs. |

Options for GE460H / GE480H:

Options for GE580H:

Options for GE590H:

Options may change and special requests may be made for customizations.