APEC SK Series – 5-Axis High Speed Gantry Machining Centers

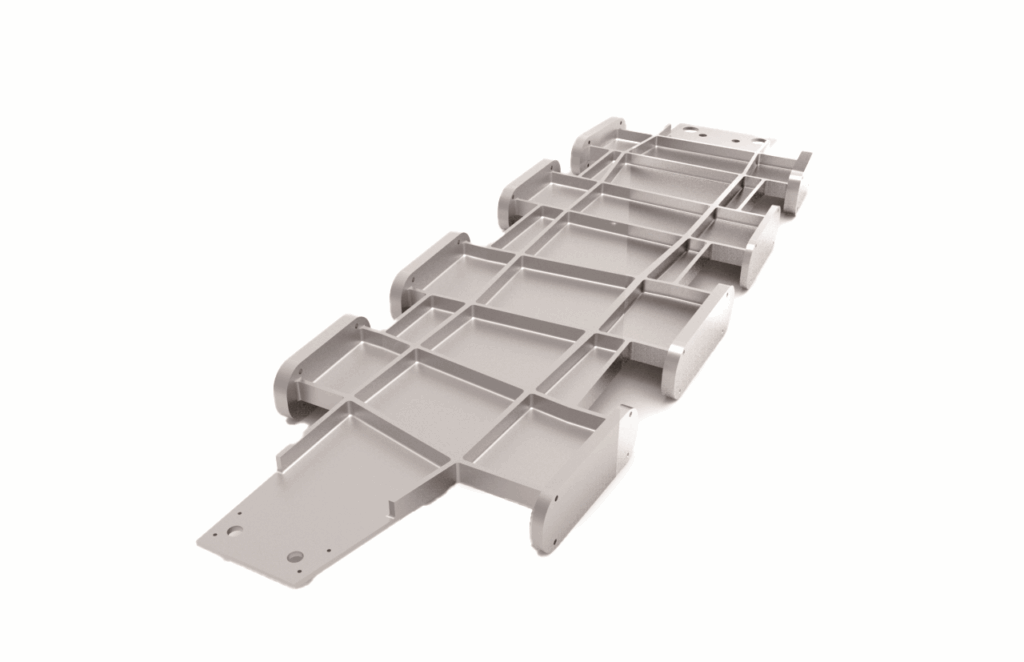

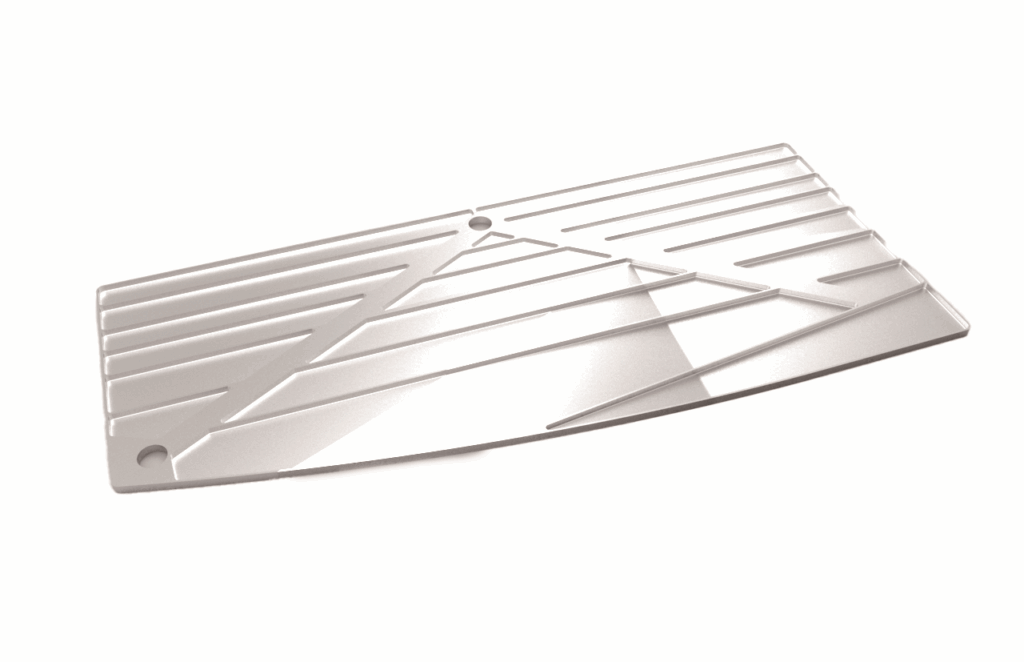

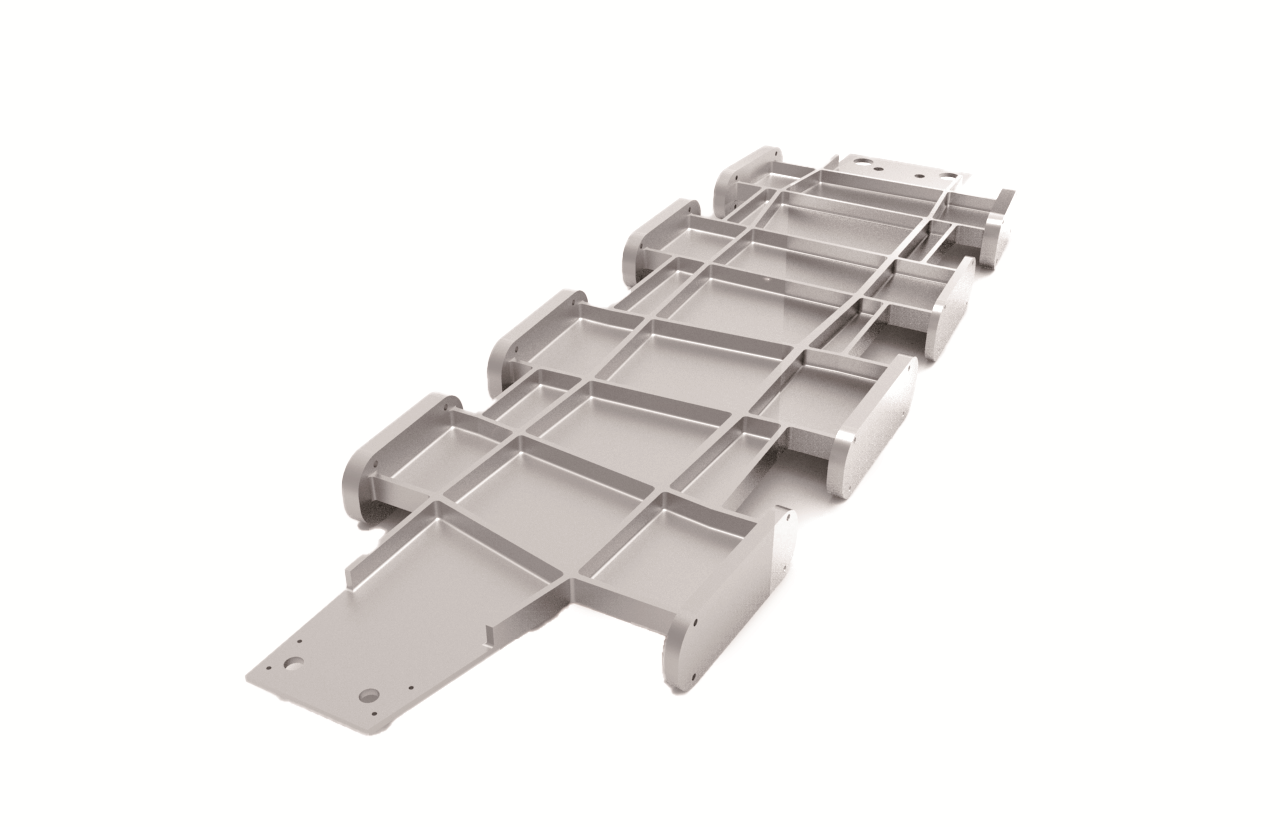

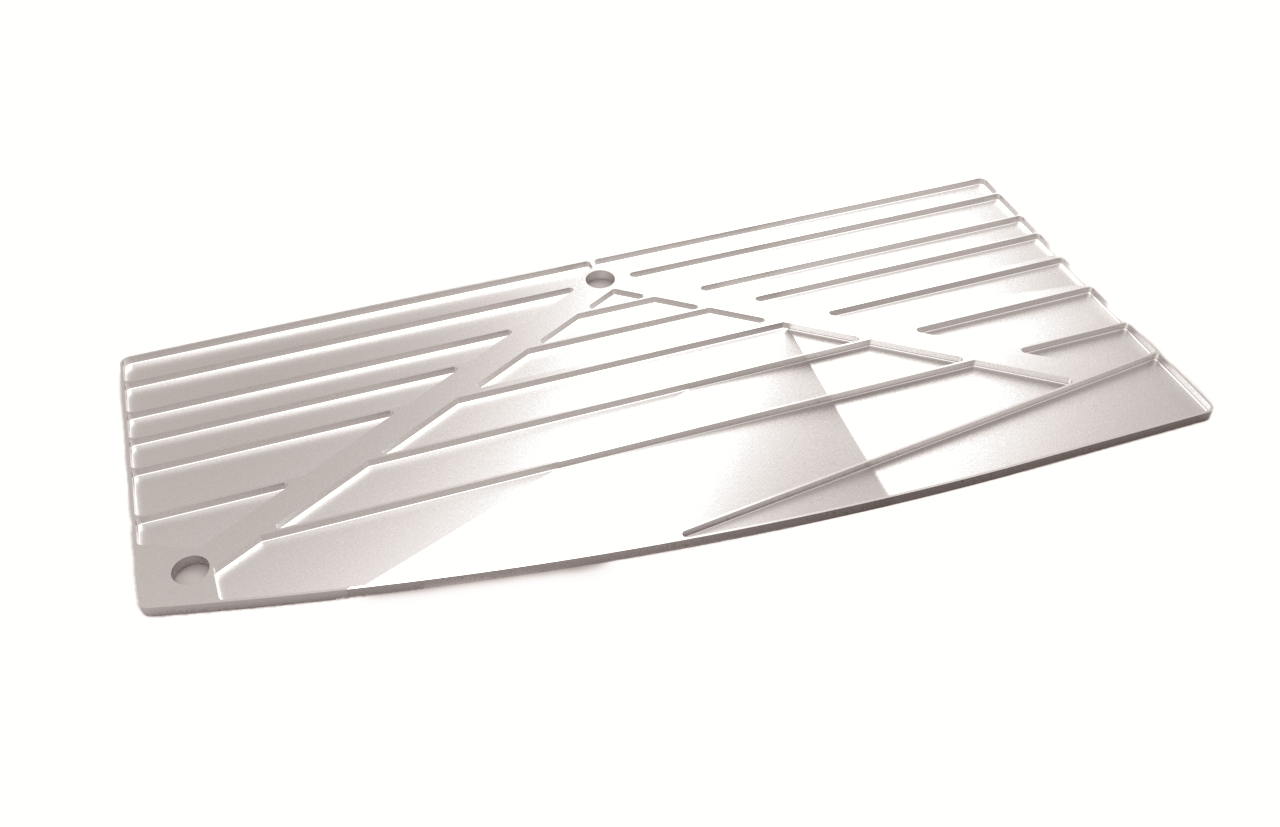

The APEC SK Series 5-Axis High Speed Gantry Machining Centers are engineered for high-speed, high-precision machining of aerospace aluminum alloy structures. Featuring APEC’s U-shape gantry structure, linear motor drives, and the industry’s lowest gravity center, the SK Series provides outstanding rigidity, vibration control, and stability in a compact, space-saving footprint. With its ability to achieve ultra-fine surface finishes on thin-walled parts, the SK Series is built to meet the accuracy and speed demands of today’s aerospace manufacturers.

Benefits for Aerospace Aluminum Machining

The SK Series helps Tier 1–3 aerospace suppliers produce complex aluminum components with superior accuracy, surface quality, and throughput. Its rigid U-shape gantry ensures stability during aggressive material removal, while linear motor drives deliver rapid positioning and smooth dynamics. Combined with advanced chip evacuation, the SK Series is designed for continuous high-volume aerospace production with minimal downtime.

Key Features

Ideal Cutting Applications

Specifications

| Item / Model |

SK2530/40/50/60/80

Request a Quote

|

SK3020/40/50/60/80

Request a Quote

|

|---|---|---|

|

X-Axis |

118.11″/157.48″/196.85″/236.22″ |

78.74″/157.48″/196.85″/236.22″ |

|

Y-Axis |

98.43″ |

118.11″ |

|

Z-Axis |

39.37″ |

39.37″ |

|

Table Length |

118.11″/157.48″/196.85″/236.22″/314.96″ |

78.74″/157.48″/196.85″/236.22″ |

|

Table Width |

787.4″ |

118.11″/98.43″/98.43″/98.43″/98.43″ |

|

Max Table Load |

17.64 lbs./ft² |

17.64 lbs./ft² |

|

Rapid Traverse |

XY=196.85 ft/min |

XY=196.85 ft/min |

|

X/Y/Z Axis Acceleration |

16.4 ft/sec² |

16.4 ft/sec² |

|

Spindle Taper |

HSK-63A |

HSK-63A |

|

Spindle Speed |

24,000 RPM |

24,000 RPM |

|

Spindle Power (S1/S6) |

80.52/100.65 HP |

80.52/100.65 HP |

|

Spindle Torque (S1/S6) |

35.39/44.25 ft. lbs. |

35.39/44.25 ft. lbs. |

|

Recommended 2-Axis Head |

Fork Type Milling Head |

Fork Type Milling Head |

|

Swivel/Rotation Torque |

B=879.77/1,456.16 ft. lbs. C=774.08/1,272.36 ft. lbs. |

B=879.77/1,456.16 ft. lbs. C=774.08/1,272.36 ft. lbs. |

|

Swivel/Rotation Speed |

B=C=30(cont)/60(max) RPM |

B=C=30(cont)/60(max) RPM |

|

Swivel/Rotation Angle |

B=±120° C=±360° |

B=±120° C=±360° |

|

Clamping Torque |

B=4,000 ft. lbs. C=4,000 ft. lbs. |

B=4,000 ft. lbs. C=4,000 ft. lbs. |

|

Tool Shank |

30T pieces |

30T pieces |

|

Max Tool Length |

11.81″ |

11.81″ |

|

Max Tool Diameter with Adjacent Tool |

Ø3.94″ |

Ø3.94″ |

|

Max Tool Diameter without Adjacent Tool |

Ø5.12″ |

Ø5.12″ |

|

Weight |

154,320 -286,600 lbs. |

154,320 -286,600 lbs. |

|

Category |

APEC SK Series |

APEC SKM Series |

|---|---|---|

|

Core Function |

High-speed 5-axis gantry machining center optimized for aerospace aluminum structural parts |

Multi-purpose 5-axis gantry machining center designed for mold & die machining with secondary aerospace capability |

|

Structural Design |

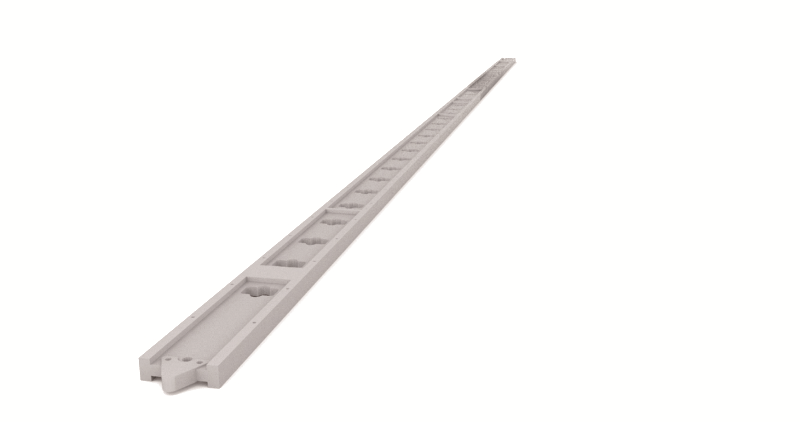

U-shape gantry structure with world’s lowest gravity center for maximum stability |

Box-in-box symmetrical design with honeycomb ram for extreme rigidity, vibration damping, and thermal stability |

|

Best For |

Aerospace aluminum alloys, thin-wall structures, high-speed contouring |

Mold & die machining (steel, graphite, precision dies) plus aerospace aluminum alloy components |

|

Spindle |

High-speed spindle (optimized for aluminum cutting, up to 24,000 rpm) |

High-speed spindle options with enhanced rigidity and stability for long-cycle mold cutting |

|

Table Design |

Large-format table with dual-drive support for long aerospace components |

Same concept, engineered to handle both aerospace parts and heavy mold bases |

|

Automation |

Compatible with pallet changers, probing, and adaptive control for aerospace work |

Same automation options, but optimized for extended mold machining cycles |

|

Highlight Advantage |

Accuracy at speed — aerospace machining with ultra-fine finishes and stability |

Versatility — equally capable in mold & die and aerospace aluminum machining |