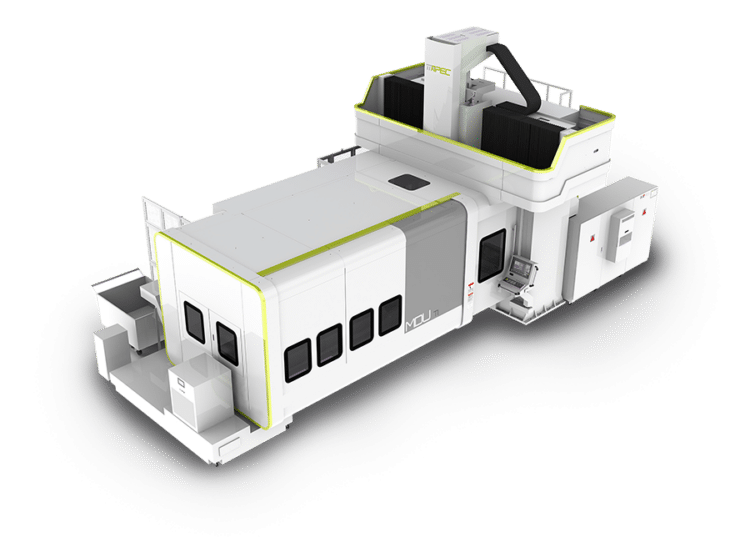

APEC MDU-Titan – 5-Axis Gantry Machining Center for CFRP & Other High Temperature Superalloys

The APEC MDU-Titan Series is a 5-axis high-torque gantry machining center equipped with an HSK-100A spindle delivering up to 6,000 rpm, purpose-built for carbon fiber-reinforced plastic (CFRP), superalloys, and high-temperature alloys. Its one-piece U-shaped casting with force-flow structural design maximizes rigidity and stability, ensuring precision under the heaviest cutting forces. Engineered for aerospace and automotive manufacturers, the MDU-Titan enables efficient machining of critical composite and alloy components where lightweight strength, performance, and accuracy are non-negotiable. Competing bridge mills such as Johnford are similar but cannot match the MDU-Titan’s balance of torque, rigidity, and CFRP-focused machining performance.

Benefits for Metal Cutting Manufacturers

The MDU-Titan delivers measurable value for manufacturers producing CFRP and alloy components. Aerospace and automotive primes, along with their tier suppliers, benefit from cycle time reduction, high accuracy, ultra-fine surface finishes, and reliable long-term stability. Customers in turn gain lighter, stronger, and safer end-products — from fuel-efficient aircraft to next-generation EVs.

Key Features

Ideal Cutting Applications

Aerospace

Automotive

These applications leverage CFRP’s high strength, stiffness, and lightweight properties, resulting in improved performance, fuel efficiency, and safety across both aerospace and automotive industries.

Specifications

| Item / Model |

MDU-Titan

Request a Quote |

|---|---|

|

X-Axis |

165.35″ |

|

Y-Axis |

110.24″ |

|

Z-Axis |

39.37″ |

|

Distance from Spindle End to Table |

13.78-53.15″(Vertical) |

|

Table Size (LxW) |

157.48 × 81.10:17, 637.5 lbs. |

|

Rapid Traverse |

X/Y=65.62′, W= 39.37’/min |

|

Spindle Taper |

HSK-100A |

|

Spindle Power |

(S1/S6) 49.57 HP |

|

Spindle Torque (S1/S6) |

737.56 ft. lbs. |

|

Tool Shank |

32T pieces |

|

Max Tool Length |

13.78″ |

|

Max Tool Diameter with Adjacent Tool |

Ø4.92″ |

|

Max. Tool Diameter without Adjacent Tool |

Ø9.84″ |

|

Weight |

44093 lbs. |