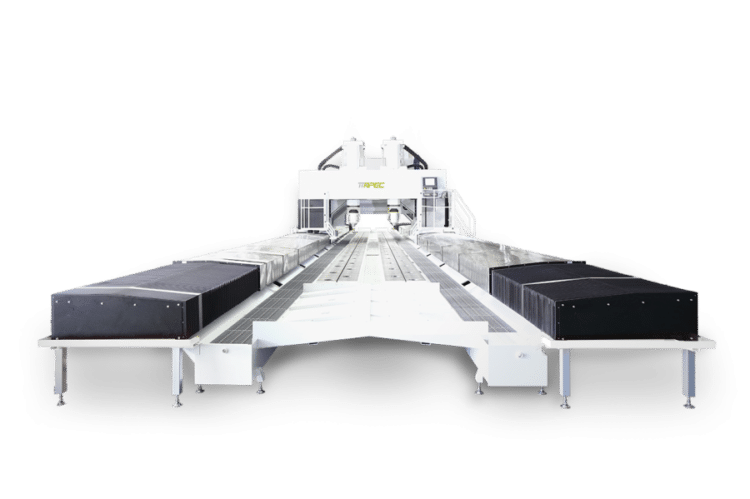

APEC MC30200-DUAL – 5-Axis Large Scale Ultra-Long Travel High Speed Bridge Mill

The APEC MC30200-DUAL is a dual-head, 5-axis ultra-long travel bridge mill designed specifically for the aerospace industry’s largest structural components. Featuring a 20,000 mm X-axis travel, dual 2-axis milling heads, dual high-power spindles, and dual tool magazines, this machine delivers productivity gains up to 200% higher than conventional single-spindle gantry mills. With Siemens Sinumerik ONE CNC control, Heidenhain optical scales, and a rigid gantry structure supported by rack-and-pinion drives, the MC30200 ensures precision machining across oversized aerospace workpieces such as wing spars, fuselage panels, ribs, and bulkheads. Competitors like Parpas, Fidia, Zimmerman, and Fooke offer large gantry mills, but none match the dual-head innovation and proven Tier 1 adoption of the MC30200.

Benefits for Metal Cutting Manufacturers

The MC30200-DUAL provides metal cutting manufacturers with unmatched stability, rigidity, and accuracy for large-format aerospace production. Its twin-spindle configuration allows both independent and synchronized machining, reducing cycle times and doubling throughput. The high-torque spindles (60/75 kW, 24,000 RPM) excel in high material removal rate (HMRR) machining of aluminum alloys and aerospace composites. By integrating a robust counterbalance system, advanced cooling, and Heidenhain scales, the MC30200 ensures thermal stability and repeatability even during long, high-speed operations. For buyers, this series provides a turnkey solution that not only meets but exceeds aerospace Tier 1 standards, with proven installations in wing spar production lines.

Key Features

Ideal Cutting Applications

Specifications

| Item / Model |

MC30200-Dual

Request a Quote

|

|---|---|

|

X-Axis |

787.4″ |

|

Y-Axis |

47.24″ + 47.24″ |

|

Z-Axis |

27.56″ |

|

Table Size (LxW) |

787.40″ x 23.62″ |

|

Rapid Traverse |

XYZ=131.23’/min |

|

Spindle Taper |

HSK-63A |

|

Spindle Speed |

24,000 RPM |

|

Spindle Power(S1/S6) |

80.48 / 100.56 HP |

|

Spindle Torque (S1/S6) |

35.59 / 44.62 ft. lbs. |

|

Recommended 2-Axis Head |

Fork Type Milling Head |

|

Swivel/Rotation Speed |

B=C=30(cont)/60(max) RPM |

|

Swivel/Rotation Torque |

B=879.73 ft. lbs./ 1,461.00 C=737.56 ft. lbs./ 1,183.30 ft. lbs. |

|

Swivel/Rotation Angle |

B=±120° C=±360° |

|

Clamping Torque |

B=8,850 ft. lbs. C=8,850 ft. lbs. |

|

Tool Shank |

20T+20T pieces |

|

Max Tool Length |

13.78″ |

|

Max Tool Diameter with Adjacent Tool |

Ø100″ |

|

Max. Tool Diameter without Adjacent Tool |

Ø150″ |