Accutex DS-2H CNC Die Sinker Series

Twin-Head and Single-Head Large-Frame CNC Die Sinkers for High-Throughput Cavity Machining

The Accutex DS-2H Series consists of large-frame CNC die sinking EDM machines available in both twin-head (2H) and single-head (SM) configurations. These machines are engineered for mold makers, aerospace tool builders, and industrial manufacturers who require high-accuracy cavity machining on large workpieces, long travel requirements, and the option to dramatically reduce cycle time using dual-ram EDM processing.

Twin-head models feature two independently controlled rams operating inside the same dielectric tank, enabling parallel machining of two cavities, synchronized burning on the same mold, or rough/finish operations performed simultaneously. Single-head SM versions use the same machine platform but provide double the X-axis travel of their twin-head counterparts, giving shops greater flexibility when machining oversized mold bases, long electrodes, or wide-format tooling.

Travel ranges span from 430mm to 1275mm per ram (860mm to 2550mm on SM single-head models), all with 1000mm Y-axis and 600mm Z-axis travel. With table load capacities from 11,000–19,000 kg, the DS-2H Series supports large molds, multi-cavity tools, aerospace dies, and deep 3D cavity structures where rigidity and accuracy are essential.

Key Features

- Twin-head 2H configuration with two fully independent rams, ballscrews, and servo control channels.

- Single-head SM configuration with double X-axis travel, ideal for long or wide-format workpieces.

- Moving-column architecture increases rigidity and stability during heavy or long-duration burning cycles.

- X-axis travel ranges:

- Twin-head 2H: 430mm, 775mm, 1075mm, 1275mm

- Single-head SM: 860mm, 1550mm, 2150mm, 2550mm

- Y-axis travel: 1000mm

- Z-axis travel: 600mm

- Large table sizes up to 3100 × 1100 mm for multi-cavity and large-format tooling.

- Exceptional load capacity from 11,000–19,000 kg to support oversized molds and aerospace dies.

- High dielectric tank capacities (3410L to 5910L) stabilize long dual-ram operations.

- 500 kg electrode weight capacity per ram for large graphite and copper electrodes.

- Advanced dual-channel CNC control supports independent ram programming, coordinated motion, orbiting, and multi-step burn routines.

Specifications

| Item / Model |

DS-1510X-2H DS-1510X Request a Quote |

DS-2210X-2H DS-2210X Request a Quote |

DS-2610X-2H DS-2610X Request a Quote |

DS-3010X-2H DS-3010X Request a Quote |

|---|---|---|---|---|

|

X Axis Travel (Twin / Single) |

17″ / 34″ |

31″ / 61″ |

42″ / 85″ |

50″ / 100″ |

|

Y Axis Travel |

39″ |

39″ |

39″ |

39″ |

|

Z Axis Travel |

24″ |

24″ |

24″ |

24″ |

|

Max Workpiece Dimension (W x D) |

81″ x 61″ |

113″ x 62″ |

129″ x 66″ |

150″ x 62″ |

|

Max Tank Filling Height |

23″ |

23″ |

23″ |

23″ |

|

Distance Between Chuck & Table |

22″ – 45″ |

22″ – 46″ |

22″ – 45″ |

22″ – 45″ |

|

Max Workpiece Weight |

24,251 lbs. |

22,046 lbs. |

22,046 lbs. |

41,888 lbs. |

|

Max Electrode Weight |

1,102 lbs. |

1,102 lbs. |

1,102 lbs. |

1,102 lbs. |

|

Table Size (WxD) |

62″ x 43″ |

89″ x 43″ |

106″ x 43″ |

122″ x 43″ |

|

Machine Weight (kg) |

35,715 lbs. |

33,070 lbs. |

39,683 lbs. |

46,297 lbs. |

|

Tank Capacity (L) |

901 Gallons |

1,230 Gallons |

1,427 Gallons |

1,561 Gallons |

|

Filter Density (µ) |

20µ |

20µ |

20µ |

20µ |

|

Filter Elements (pcs) |

12 Pieces |

12 Pieces |

12 Pieces |

12 Pieces |

|

Max Working Current (A) |

120 Amps |

120 Amps |

120 Amps |

120 Amps |

|

Overall Power Consumption (KVA) |

12 KVA |

12 KVA |

12 KVA |

12 KVA |

|

Weight (kg) |

838 lbs. |

838 lbs. |

838 lbs. |

838 lbs. |

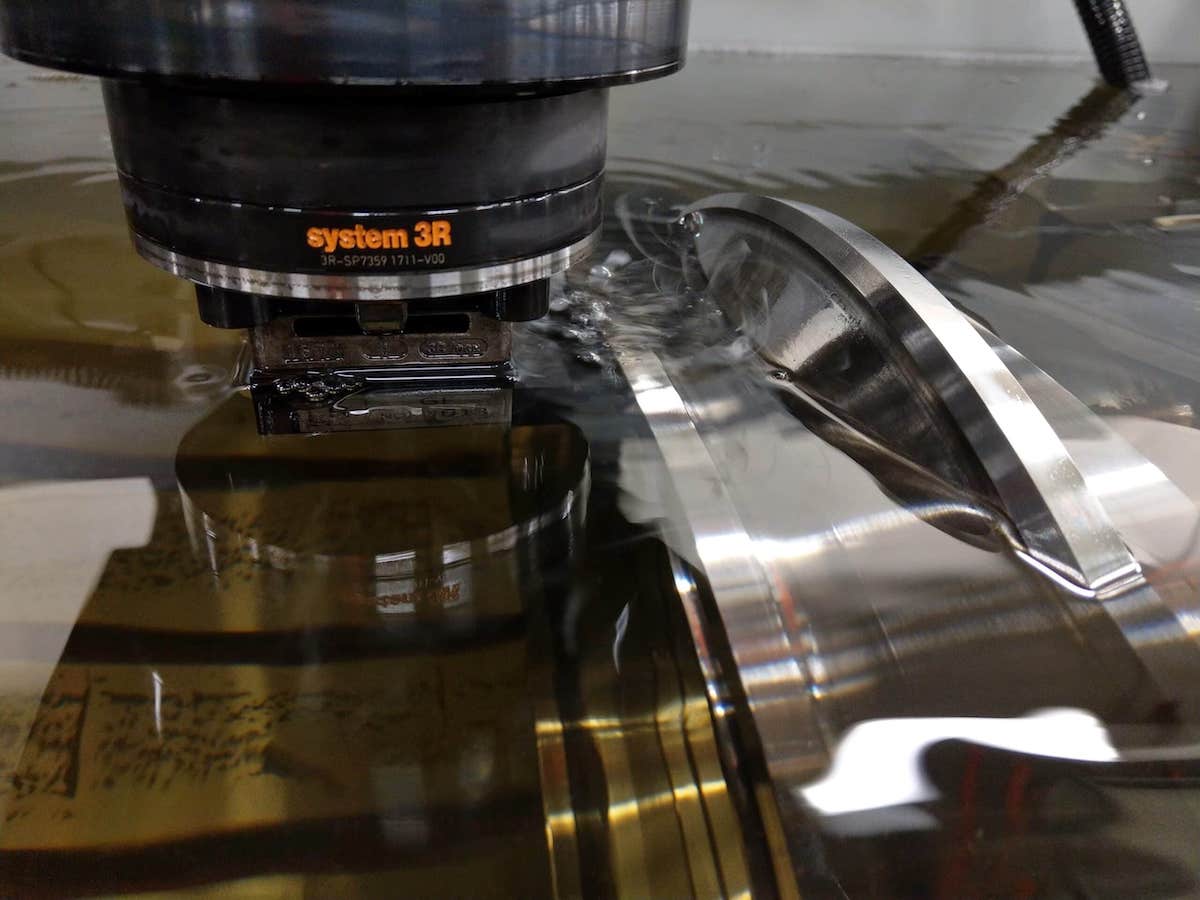

Benefits for Metal Cutting Manufacturers

Ideal Cutting Applications

Production Line Automation & Integration using Accutex’s Manufacturing Execution System (MES)

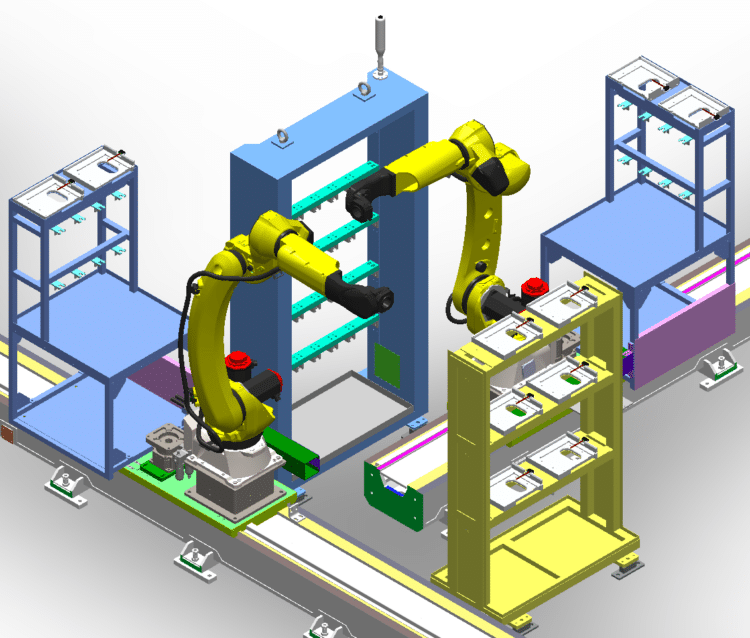

Accutex’s Manufacturing Execution System, or MES is the latest in advanced smart technology and AI. MES not only monitors every aspect of the production process including recording and displaying real-time data on just about any electronics you can think of, but can also manage things such as multi electrodes, workpieces and machines. Data produced during machine monitoring includes utilization rates, status, and machining processes including milling. MES can also manage customized tools and design projects, measurements and counts necessary in mass-production processes and warehouse management.

MES incorporates Radio Frequency Identification (RFID) technology to record and track real-time data for managing tools and program details. For instance, tools tagged with RFID can be inserted in random positions. Using a robot, RFID tags can be scanned and sorted according to scheduled operations and priorities within the program increasing efficiencies and removing potential errors.

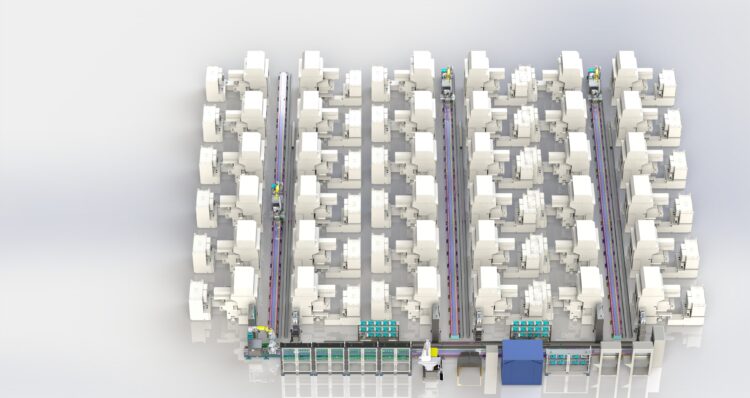

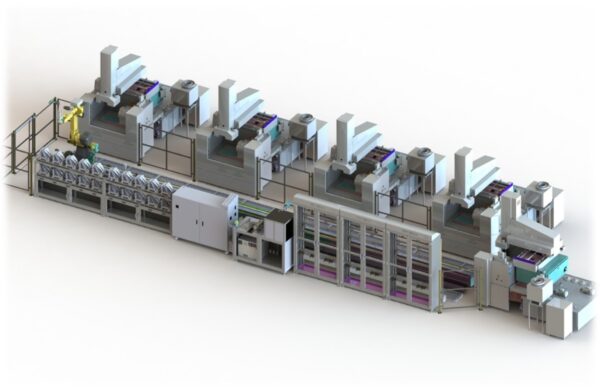

Below are simulations pictures of a recently installed production lines using Accutex die sinkers and MES: