AccuteX DS-X Series – CNC EDM Die Sinkers

AccuteX DS-X EDM Die Sinkers are a RAM type CNC EDM machine offering a full range of sizes and capabilities built with rigid heavy-duty Meehanite casting designed using Finite Element Analysis (FEA) to ensure rigidity and precision accuracy.

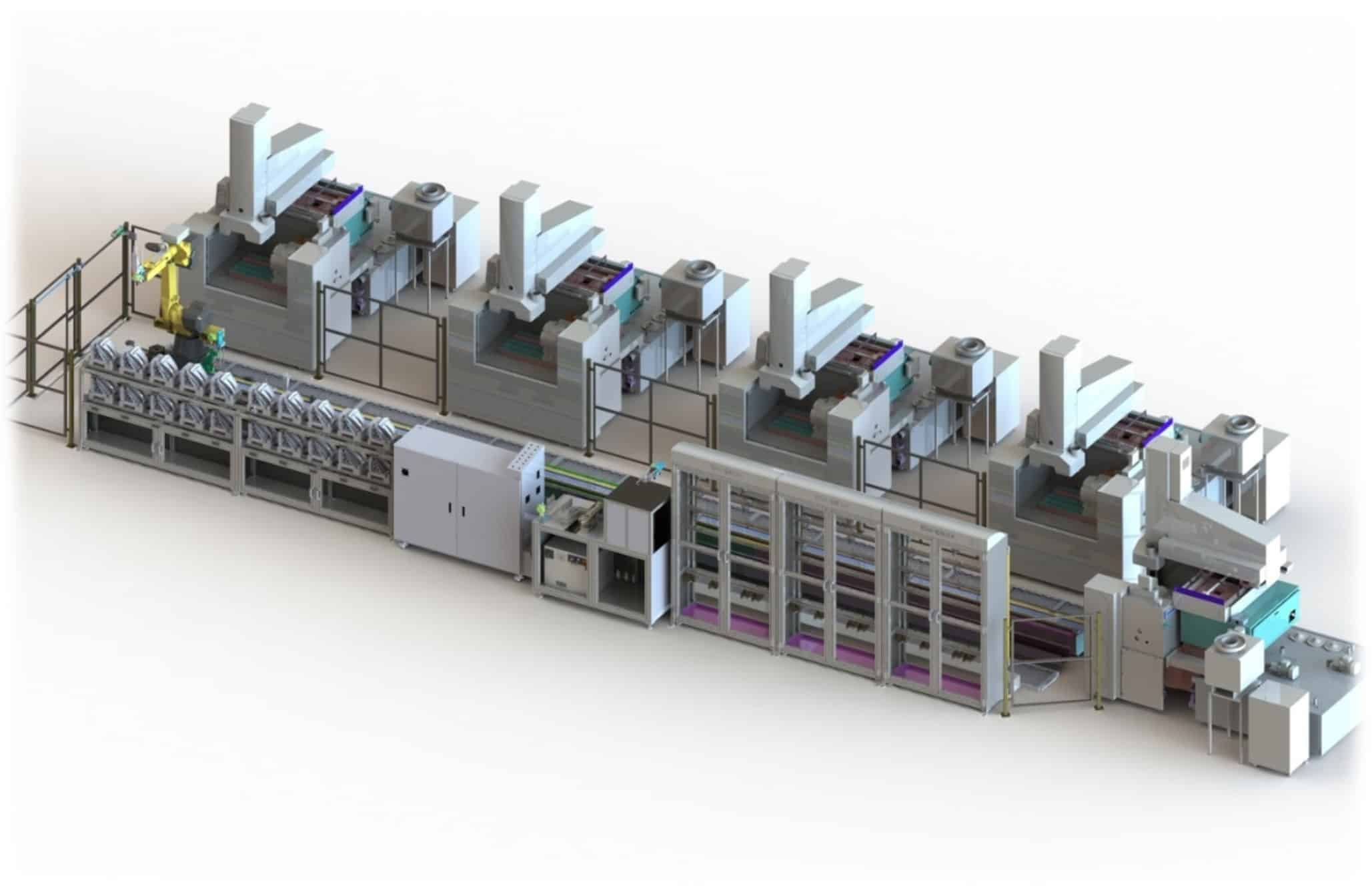

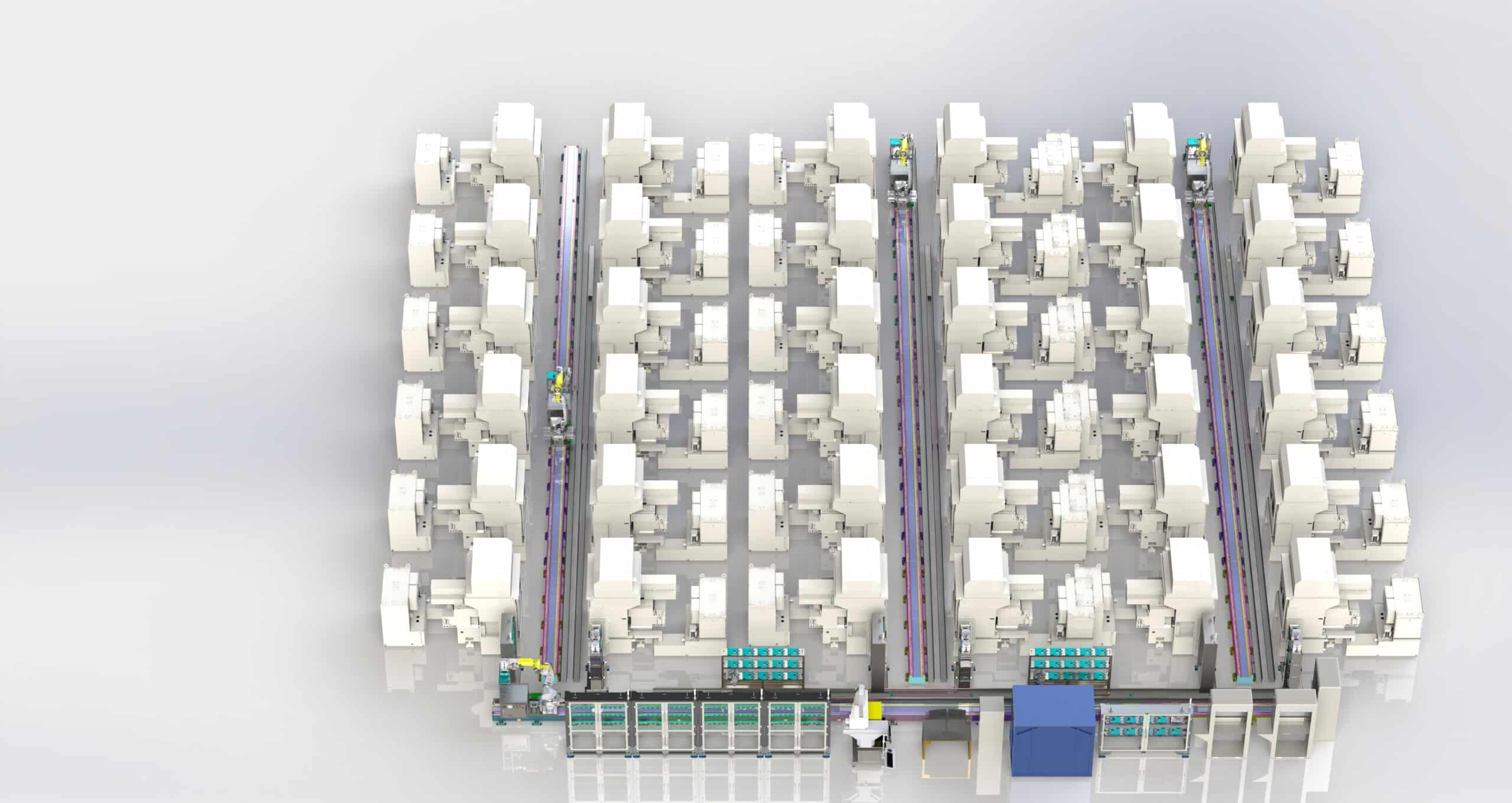

The series begins with the DS-430X moving table-type CNC die sinker machine followed by moving column type models ranging in size from DS-500X up to DS-3010X. Travels range from 400mm (16″) – 3000mm (118″) in X, 300mm (12″) – 1000mm (39″) in Y, and finally 300mm (12″) – 600mm (24″) in Z. For larger heavier workpieces, or to burn two large workpieces simultaneously, the AccuteX DS-2H twin head design is also available. The DS-X twin head (twin ram) series includes models ranging from DS-1510X-2H up to DS-3010X-2H and can be built in a twin head (2H) or single head design, allowing for maximum production and versatility on the big jobs.

AccuteX EDM also offers the DS-ZNC series of manual die sinkers. All ZNC model die sinking EDM machines offer an NC-controlled X, Y axis option that allows for a wide range of operations only available on full 3D machines. Multiple cavity positioning, X or Y axis side machining, auto centering, fuzzy auto set parameter setting and X,Y axis orbiting using the COC-280 integrated orbit head make the AccuteX DS-NC series boost cost effectiveness and productivity.