Medical

Industry

Medical Industry CNC Machine and Automation Solutions

In the realm of life-saving devices, surgical instruments, diagnostic systems, and orthopedic implants, the very foundation of success rests upon the machinery that manufactures them. There’s no room for compromise, as these elements must not only endure fatigue resistance but also embody impeccable biocompatibility. At Absolute Machine Tools, we recognize the critical role precision machining plays in shaping the future of medical innovation.

Expertise in CNC Machine and Automation Engineering for the Medical Industry

We are proud to bring our unparalleled CNC machine and automation engineering expertise to the forefront of the medical industry. With a proven track record of excellence, we have established ourselves as a reliable partner for medical device and implant manufacturers seeking innovative solutions and precise, high-quality machinery. Our commitment to delivering cutting-edge technology and unwavering support sets us apart as a trusted resource in the medical sector.

Our commitment to excellence drives us to engineer solutions that redefine the boundaries of precision and speed. In the realm of high-durability materials like cobalt-chrome alloy, nickel-titanium (nitinol), platinum, silver, and tungsten, we stand as vanguards of innovation. Our machines not only meet but exceed the demands of the medical sector, delivering unparalleled precision and faster cycle times.

Pioneering Precision for Complex Medical Geometries

Before the advent of advanced machining applications, the intricate geometries of human joints and implants posed an insurmountable challenge to manufacturing. Enter our team of dedicated engineers, whose expertise thrives at the intersection of innovation and practicality. Through meticulous design and development, we engineer custom machine tool integrations that harness the full potential of the latest machining technologies.

Premier CNC Machine OEMs Represented for Medical Applications

We proudly represent a curated selection of renowned CNC machine OEMs that specialize in applications relevant to the medical industry. Each of these manufacturers shares our commitment to precision and reliability. Our lineup includes:

Machines

Combination Moving Column & Table-type designs, 4 – 5-Axes, 400mm – 2500mm Capacities, and True Independent Twin Spindle models

6-10″+ Chucks with Sub-spindles, Multi-turret, Integrated Automation, Pallet-changers, Side-head machining, Y-Axes, and a variety of ATC model Lathes

Multi-Slide, Multi-Tasking, Multi-Axis Mill-Turn Centers for machining complex workpieces

7-11 Axes, B-Axis configurations, Opposing Gang Tooling Systems, and Exchangeable Guide Bushing Swiss Lathes

Vertical Machining Centers with Drill/Tap capabilities, 24K+ RPM spindles in Single & Twin, 3 – 5-Axes, Linear Ways, Box Ways, Geared Heads, C-Frame, Up to 6M travels all for Mold & Die Applications and Electrode manufacturing

Applications

At Absolute Machine Tools, we understand the critical role CNC machines play in the medical industry. Our dedication to providing top-tier machinery and unparalleled support makes us the ideal partner for medical equipment manufacturers seeking precision, reliability, and innovation. Complete the form below to contact us today to explore how our CNC solutions can elevate your medical manufacturing processes to new heights.

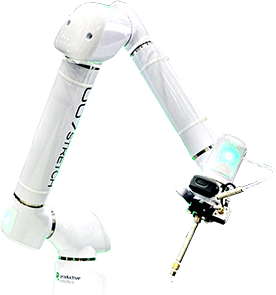

Embracing Automation

Our A+ Automation team offers simple and affordable solutions for CNC machine automation

The Absolute Advantage

- Unmatched Expertise: With years of experience in the automotive industry, we have in-depth knowledge of the challenges you face. Our team of experts is dedicated to understanding your specific needs and providing customized solutions that drive your success.

- Cutting-Edge Technology: We stay at the forefront of technological advancements in the automotive industry. By partnering with us, you gain access to the latest innovations that enhance your manufacturing capabilities and give you a competitive edge.

- Superior Quality & Reliability: At Absolute Machine Tools, quality is our top priority. We partner with renowned manufacturers known for their precision and reliability. Our machines undergo rigorous testing to ensure they meet the highest standards, guaranteeing exceptional performance and longevity.

- Comprehensive Support & Training: We don’t just provide machinery; we provide complete support and training to ensure your team is fully equipped to leverage our solutions effectively. Our experienced technicians are always available to provide assistance, training, and ongoing support, ensuring optimal performance and minimal downtime.

Partner with Absolute Machine Tools Today

When it comes to automotive manufacturing excellence, Absolute Machine Tools is the partner you can trust. We are committed to helping you achieve operational efficiency, maximize productivity, and stay ahead in the competitive automotive industry. Complete the contact form below to learn more about our cutting-edge machinery and customized solutions tailored to your unique needs. Together, let’s drive success in the automotive manufacturing landscape.

OEMS

AccuteX EDM Machines

AccuteX Wire EDM CNC machines enable manufacturers to create intricate medical components with unmatched accuracy. From complex surgical instruments to critical implant components, these machines empower you to shape the future of medical technology.

AccuteX machines merge advanced technology with decades of expertise, creating a harmony that caters to the intricate needs of the medical sector. This experience and expertise streamlines your production processes, accelerates innovation, and takes your medical manufacturing to new heights.

LICO Multi-Slide CNC Screw Machines

From micro-components to complex screws, LICO machines empower you to craft vital components with meticulous accuracy.

The hallmark of LICO lies in its commitment to innovation. These cutting-edge machines blend advanced technology with decades of craftsmanship, resulting in a harmonious synergy that caters to the diverse requirements of the medical industry. This synergy transforms your production processes, optimizes efficiency, and paves the way for groundbreaking innovation.

Quicktech Multi-Axis Multi-Spindle Mill-Turn Centers

QuickTECH mill-turn centers redefine the medical manufacturing landscape, enabling manufacturers to craft intricate medical components with extraordinary accuracy. From surgical instruments to complex implants, these machines empower you to meet the exacting standards of the medical field.

QuickTECH machines seamlessly combine milling and turning capabilities, offering a comprehensive solution for the multifaceted demands of medical manufacturing. This integration streamlines your processes, enhances efficiency, and opens new avenues for innovation.

Nexturn Swiss Lathes

Designed to meet the intricate demands of medical component manufacturing, Nexturn’s cutting-edge machines epitomize precision, efficiency, and innovation.

In the realm of medical device production, precision and reliability are non-negotiable. Nexturn Swiss lathes stand as a cornerstone in this pursuit, delivering unmatched accuracy in crafting complex medical components. From intricate implants to surgical instruments, Nexturn Swiss-style lathes empower manufacturers to achieve the highest standards of excellence.

What sets Nexturn apart is its commitment to versatility. These lathes are engineered to work seamlessly with a diverse range of materials, including surgical-grade metals, polymers, and ceramics. This adaptability ensures that medical manufacturers can create components that meet the stringent requirements of the industry.

Ocean Technologies Precision Small Hole Drilling EDM Machines

Ocean Technologies’ small hole drilling machines excel in creating small, high-precision holes in materials like surgical-grade metals and alloys, ceramics, and polymers.

The medical industry demands components that adhere to the highest standards of quality and precision. Ocean Technologies’ EDM machines are tailored to meet these demands, enabling the production of implants, surgical instruments, and other critical medical components with unparalleled accuracy.

What sets these machines apart is their ability to work with diverse materials, intricate geometries, and challenging depths. Ocean Technologies’ hole drilling machines are poised to elevate your capabilities, enabling you to shape the future of healthcare technology.

Learn More About Ocean Technologies

Precihole Advancing Medical Implants with Precision Deep Hole Drilling Machines

In the realm of medical implants, precision deep hole drilling takes center stage. Surgical-grade titanium and steel materials define these critical components, boasting a high strength-to-weight ratio and corrosion resistance. Deep hole gun drilling carves holes as small as 1.5mm in diameter into slender titanium workpieces.

These holes can stretch to remarkable length-to-diameter ratios of up to 350 – 400, introducing the challenge of drilling into the notoriously tough but biocompatible material—titanium. Precihole’s machine design innovations enable precise, long hole drilling with impressive parameters.

In the medical industry, Precihole machines find their purpose in crafting bone screws, femoral nails, tibial nails, and other surgical instruments.