Gun

Drilling

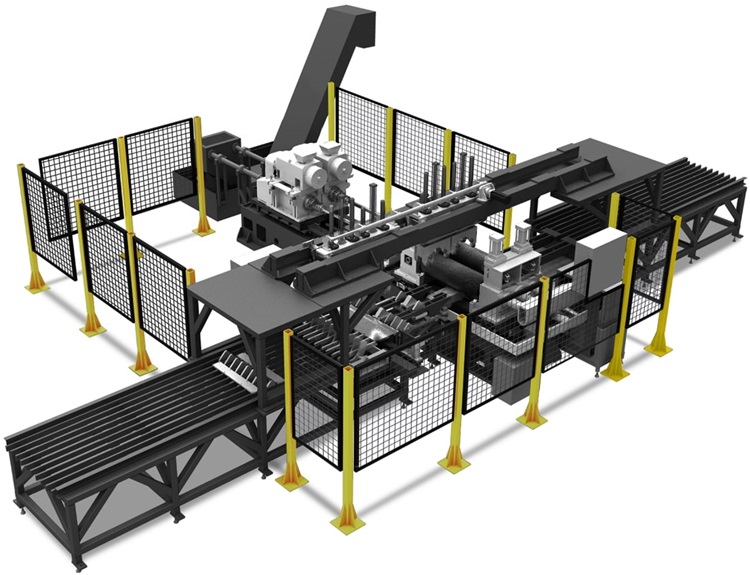

Precihole Gun Drilling Solutions

Gun drilling is a deep hole drilling process that implements a long, thin cutting tool to produce deep and straight holes with high depth-to-diameter ratios. This operation was initially developed for machining gun barrels, where both straightness and barrel durability were essential to properly functioning barrels and accuracy.

The gun drilling process is primarily used to drill deep holes beyond what is possible with conventional twist drilling machinery. The standard gun drill tool geometry has a single effective cutting edge. Unlike the twist drill, the gun drill cuts through the metal eccentrically, and, once inside the component, the tool self-pilots itself. The hole is further burnished due to the guide pads which finally results in a precise round hole with maintained straightness. The coolant enters the tool through the coolant through hole and the chips are gushed out through the V shaped profile on the gun drill. Gun drilling is effective from ф 1mm to ф 30mm, but if you wish to go higher BTA drilling becomes more effective than gun drilling.

Firearms are a common application for gun drilling; however, other common uses are moldmaking, diemaking, medical tooling, plastics/injection molds, combustion engine components, crankcases, cylinder heads, musical instruments, and more.

ABSOLUTE IS A PROUD SUPPORTING MEMBER OF THE NSSF