Picking the Proper End-effector is an Important Additional Cost to Consider When Purchasing a Cobot

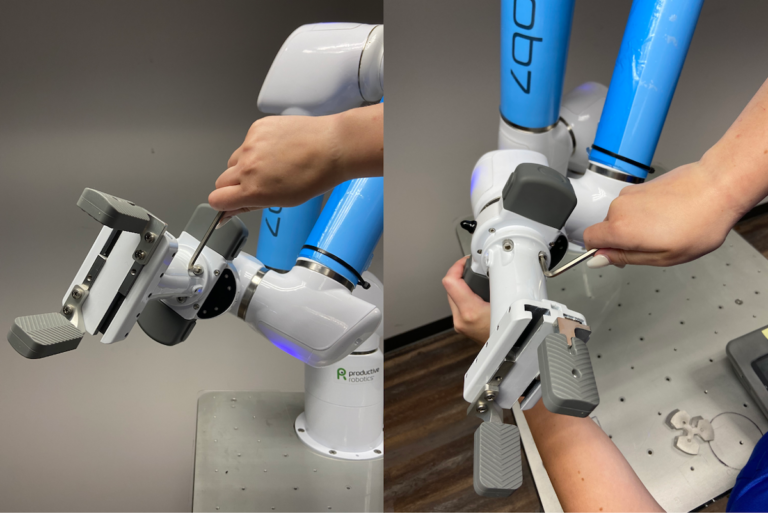

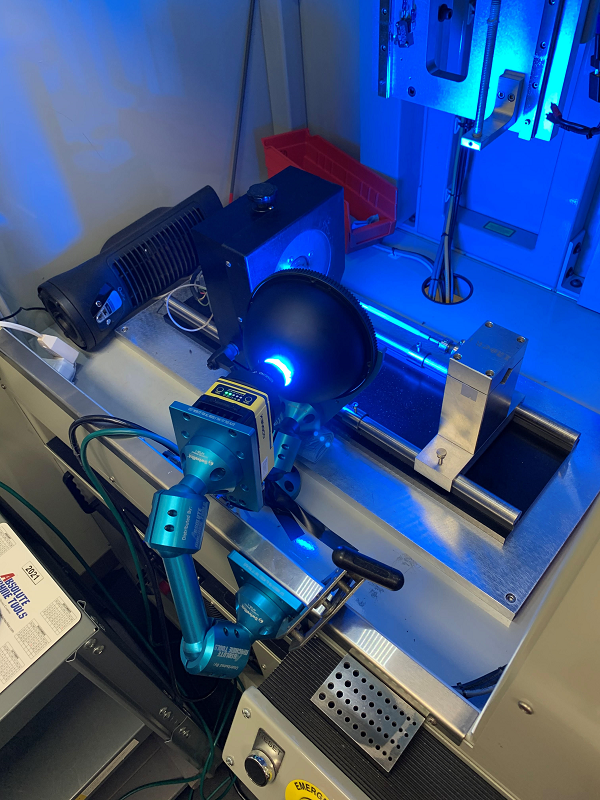

End-effectors — EAOT — grippers — whatever you want to call them are fundamental to an application’s success. End-effectors are considered the business end of every cobot, and there are hundreds of different types in the marketplace today. What you use will depend entirely on the parts the cobot is handling. If the cobot is painting, polishing, sanding, or deburring, that will require different types of end-effectors or EAOT.

How Does Your End-Effector Work?

End-effectors can be driven or powered electronically, hydraulically, mechanically and pneumatically (air). Those controlled electronically are the most flexible. Vacuum is also a very popular end-effector that uses suction cups or other vacuum surfaces for picking up oddly shaped objects.

Sometimes, for specialized functions, very complex devices must be custom-designed and manufactured, and those with an in-house 3-D printer can have the most flexibility because they can design and print their own.

End-Effector Payload Capacity

Then, there needs to be consideration for the science behind the maximum payload the cobot is rated for. This is called “inertia.”

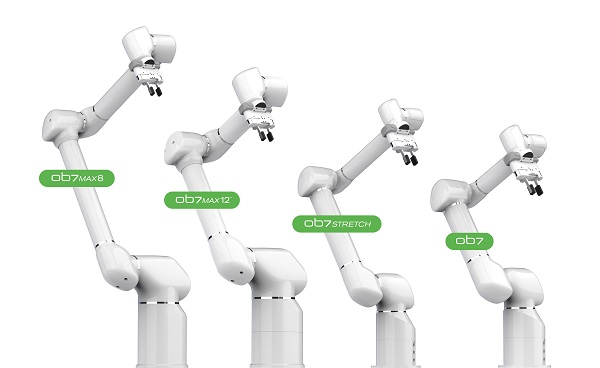

Inertia can greatly affect the performance of the cobot. Inertia must be considered when choosing a cobot and end-effector. If the part is going to be held close to the end-effector, and the end-effector is close to the cobot’s face plate (at the end of the arm), then typically you can go by the payload rating of the cobot (taking into consideration the weight of the EAOT).

However, if the part is held in distance from the end-effector, and the end-effector is not close to the cobot’s face plate, then the center of gravity is off balance and inertia is certainly going to effect the cobot’s payload rating, which will ultimately inhibit its performance. That’s when you have to go back to the drawing board and decide if there’s a better way.

Most Common Types of End-Effectors

There are many different types of end-effectors, but the following 3 are the most common:

How to Pick the Right Cobot End-effector

After you and your automation provider have thoroughly reviewed the part that you need the cobot for and determined the way it will be handled, you’ll need to determine the best end-effector. The following are tips that can help you determine the right one:

- Determine the action or movement the cobot is going to perform.

- Research the different types of end-effectors that can deliver the most efficient action or movement required.

- Consider the cost, complexity, and availability of the end-effector(s) you are considering.

- Determine the type you will need to purchase, i.e., pneumatic, electronic, mechanical, etc.

- Consider the payload of the end-effector + part weight + inertia.

- Pick the end-effector that best fits this job and not the one you feel is universal to all current or future projects.

Did we just say don’t consider the future? Yes, we did. Typically, a cobot is used for a particular job, hence the end-effector should be picked the same way. If you try and pick one that can be used in many different ways, it may not be the most efficient for the task at hand. Remember, the end-effector acts like your hand, and if that doesn’t work properly, well then your end-effector won’t either. There are a multitude of end-effectors and most are reasonably priced, so get the one that will work best for this process.

Consider Communications Between End-Effector and Cobot

Another thing to consider with end-effectors — communications between it and the cobot. Because there are a multitude of different end-effectors, there are also a multitude of different communication protocols and interfaces that are used. We suggest talking with your cobot provider as to which one will work the best with the cobot they’re proposing, and the skill level needed by the operator to get the end-effector and cobot to communicate. You may need the help of the cobot provider to train the operator on the first use.

Get Help Choosing the Right End-Effector for Your Needs

Finally, ask your cobot provider for guidance when choosing an end-effector. Oftentimes they have already had a lot of experience with a variety of products. Check to make sure that your cobot provider can supply the end-effector with the cobot as a package.

Remember, these are critical and costly decisions, and that is where an automation integrator such as Absolute Machine Tools can help. Our A+ Automation Team works closely with its customers and OEMs to ensure the customer is getting the best products that meet their needs. End-effectors, or EAOT, should be determined before the cobot shows up on your floor. A good automation integrator should always study the part(s) and make recommendations. If they recommend a particular end-effector, or EAOT, without the benefit of studying your parts, find someone else.

Contact the A+ Automation Team at Absolute Machine Tools today at info@absolutemachine.com to get help implementing a cobot in your operations!