AccuteX GA Series – Moving Table Submerged-Type Small Footprint Wire EDM + NEW ueX10 CNC Control featuring an improved “User’s Experience”

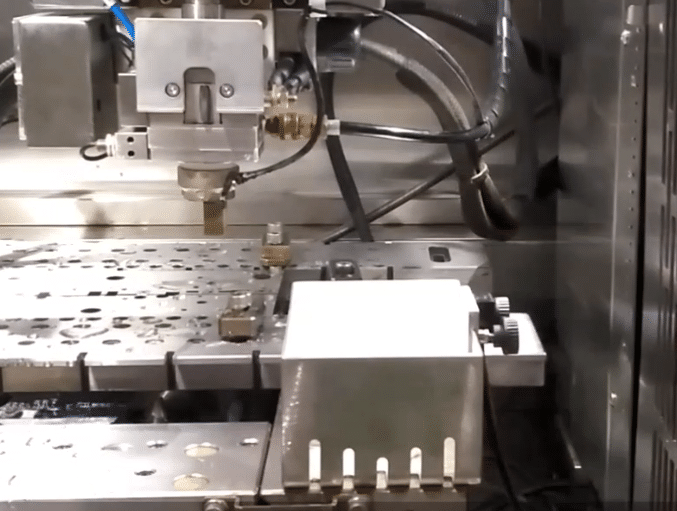

The Accutex GA Series moving table submerged-type CNC Wire EDM machines are designed with a small footprint for manufacturing plant space efficiency. This series is built with cutting edge linear motor shaft drive technology. Like its predecessor, the GE Series, the GA series boasts its ergonomic space saving design, drop door, 3-sided table (back rail optional), patented fully annealing automatic wire threader and submerged machining capabilities of up to 8″ or 195mm.

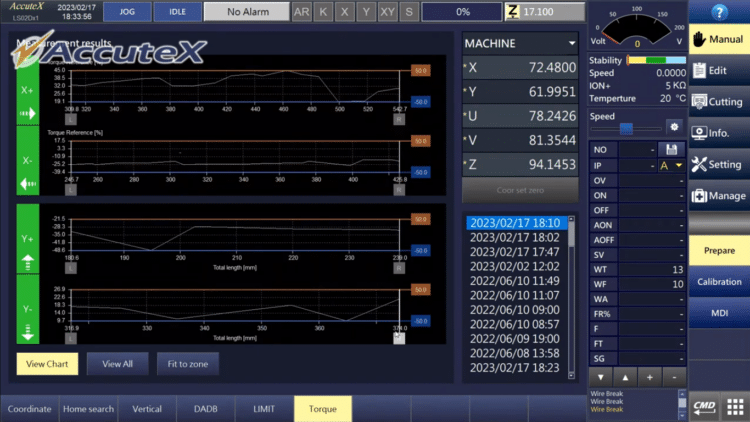

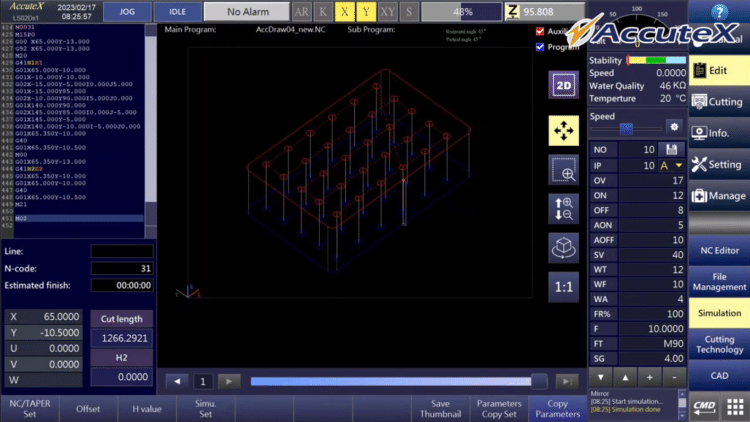

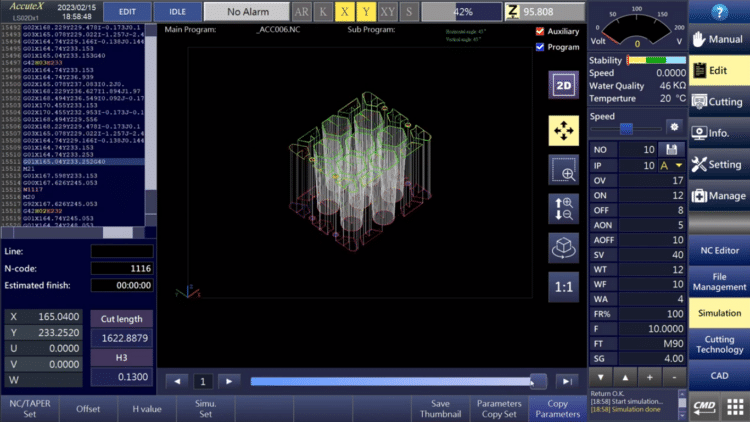

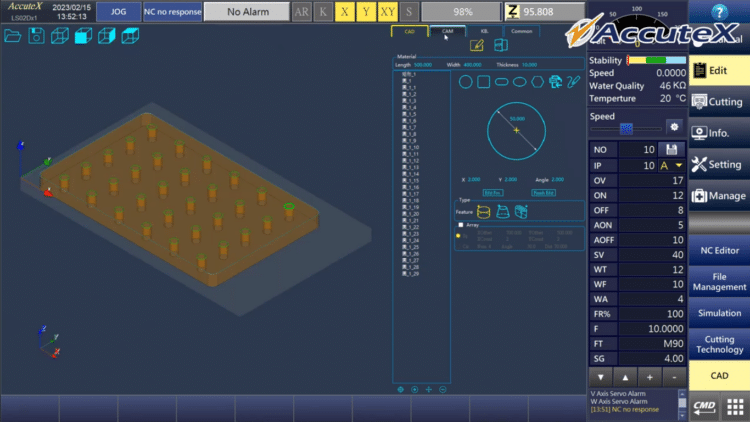

However, this new series is equipped with the latest and most advanced high-tech EDM CNC control in the market today. Introducing the NEW ueX10 CNC control from Accutex EDM! The ueX10 CNC control is the result of a five-year development project between Accutex EDM in Taiwan, and Absolute Machine Tools. It is designed with a “USER EXPERIENCE” focus for enhancing capability and productivity, and easily integrates with new options/features and continued technological advancements. With a 21.5″ touch screen and Windows 10 operating system, the ueX10 is fully supported and will be easily updated with future Windows Operating Systems. The ueX10 EDM CNC control features cloud-based applications, automation, and network monitoring.

Key Benefits:

Linear Motor Drive System:

The GA Series uses a direct-drive linear motor system that eliminates backlash and ensures smooth, friction-free motion. Because of the linear shaft motor design, the GA series can provide 10% faster servo response time than flat-type linear motors with no thermal distortion or friction. The linear shaft motor, HIWIN linear guideways, 0.000008” Fagor glass scales and 64 bit processing are joined together on the massive casting putting the GA Series in a class of its own. The U and V axis mechanism is still designed with rigid 20mm C1 Class ballscrews to maximize cutting pressures for high-speed cutting.

NEW uex10 CNC Control:

The NEW ueX10 Wire EDM CNC control was designed with improvements such as:

Automatic Wire Threading (AWT):

The AccuteX AWT System offers fast and reliable wire threading, even in submerged operations. This reduces downtime and enhances productivity by enabling unattended machining, perfect for lights-out manufacturing.

Cost-Effective Wire Consumption:

The GA Series is designed to minimize wire consumption, lowering operational costs while maintaining precision and cutting efficiency.

Thermal Stability and Durability:

The machine’s thermally stabilized design reduces the effects of temperature fluctuations, ensuring consistent accuracy during long production runs. The robust construction also enhances overall machine longevity.

Performance Advantages:

Specifications

| Item / Model |

GA-43AL

Request a Quote |

|---|---|

|

X Axis Travel |

15.75″ |

|

Y Axis Travel |

11.81″ |

|

Z Axis Travel |

8.66″ |

|

U Axis Travel |

2.36″ |

|

V Axis Travel |

2.36″ |

|

Table Feed Rates |

40.0 IPM |

|

Max. Taper Angle |

±45° |

|

Max. Workpiece (XYZ) |

29.52″ x 24.80″ x 8.46″ |

|

Max. Workpiece Weight |

1,067 lbs. |

|

Wire Diameter |

0.006″ – 0.013″ |

|

Wire Spool Feed Rate |

60 – 787 IPM |

|

Wire Tension |

300 – 2,200 grams |

|

Start Hole Diameter |

0.020″ ∅ |

|

Max. Wire Spool Weight |

22 lbs. |

|

Positioning Accuracy |

0.00012″ |

|

Repeatability (XY) |

0.00008″ |

|

Total Power Required |

15 KVA |

|

Deionized Resin Tank |

935 0.4 cu/ft Fiberglass Bottle |

|

Tank Capacity |

220 Gallons |

|

Floor Space |

94″ x 108″ x 78″ |

|

CNC Control Screen |

21″ Color Monitor |

|

CNC Control Device |

ueX10 Windows 10 PC |

|

Weight |

5,830 lbs. |