Industry-Leading Automotive Machinery and Solutions

At Absolute Machine Tools, we understand the dynamic and demanding nature of the automotive industry. As a leading provider of cutting-edge machinery and solutions, we are dedicated to empowering automotive manufacturers with the tools they need to stay ahead in this competitive market. With our state-of-the-art equipment and unwavering commitment to quality, precision, and efficiency, we are your trusted partner for all your automotive manufacturing needs.

Your Partner in Automotive Manufacturing Excellence

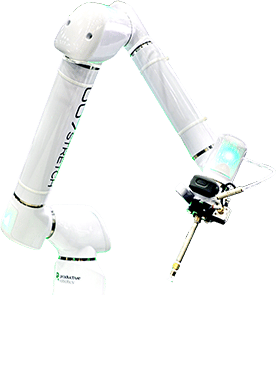

Our comprehensive range of automotive machinery is designed to optimize your production processes and enhance your manufacturing capabilities. Whether you’re involved in engine component manufacturing, precision machining, or automotive part production, we have the perfect solution for you. No matter what your application or machining requirement, you’re sure to find exactly what you’re looking for at Absolute. Ranging from bridge mills to drill and tap centers, flat bed and slant bed lathes to Swiss lathes and screw machines, and large industrial robots to collaborative robots, we have it all.

Machines

Oems

AccuteX wire EDM machines are cruicial in the automotive industry for mold and die making, tool and die maintenance, gear manufacturing, fuel injection components, and the production of turbines and engine components. These machines enable precise machining of intricate shapes and details required for critical automotive parts, ensuring optimal performance, reliability, and safety of vehicles. With high accuracy and tight tolerances, AccuteX EDM technology excels in producing complex gear profiles, restoring tooling elements, manufacturing fuel injection components, and shaping engine parts. When it comes to automotive manufacturing, AccuteX EDM machines play a vital role in delivering high-quality, precise components for optimal performance and safety.

Johnford CNC machines are essential equipment used in the automotive manufacturing industry. These machines are specifically designed to handle large-scale components and perform precision machining operations required in automotive production. Bridge mills are utilized for milling, drilling, and contouring tasks on large automotive parts, such as engine blocks and chassis components. Boring mills are employed to create precise bores and holes in engine cylinders, transmission cases, and other critical components. Large lathes are used for turning operations, shaping cylindrical parts like shafts and axles with high accuracy. The use of Johnford machines ensures the production of quality automotive components that meet stringent industry standards for performance and reliability.

LICO CNC screw machines are specifically designed to efficiently produce high-precision automotive components. These machines excel in tasks such as turning, threading, and complex machining operations required for the production of various automotive parts like engine valves, pistons, connectors, and fittings. With their capability to handle a wide range of materials and intricate designs, LICO CNC screw machines ensure excellent accuracy, tight tolerances, and rapid production. By leveraging LICO CNC screw machines, automotive manufacturers can achieve enhanced productivity, superior quality, and cost-efficiency in the production of critical components for vehicles, contributing to the overall success and competitiveness of the automotive industry.

Nexturn Swiss lathes are essential tools in the automotive manufacturing industry, offering exceptional precision and versatility. These advanced machines are specifically designed to handle the complex machining requirements of automotive components. Nexturn Swiss lathes excel in tasks such as turning, milling, drilling, and thread cutting, allowing for the production of high-quality parts like engine shafts, connectors, and precision screws. With their ability to handle various materials and intricate designs, Nexturn Swiss lathes ensure tight tolerances, superior surface finishes, and efficient production. By leveraging Nexturn Swiss lathes, automotive manufacturers can achieve enhanced productivity, accelerated turnaround times, and superior quality in the manufacturing of critical components.

Ocean Technologies’ advanced machines are specifically designed to create small, high-precision holes in automotive components. Ocean Technologies small hole drilling EDM machines are widely used in the production of fuel injection nozzles, injector parts, and other critical engine components that require tight tolerances and exceptional accuracy. With their capability to handle a wide range of materials and complex geometries, these machines ensure optimal performance, reliability, and fuel efficiency. By utilizing Ocean Technologies small hole drilling EDM machines, automotive manufacturers can achieve superior quality, cost-effectiveness, and faster production times, allowing them to strengthen their position in the competitive market.

In the automotive industry, precision and uninterrupted production are paramount. Precihole offers state-of-the-art gun drilling and BTA deep hole drilling machines specifically designed to meet these requirements. Precihole machines are renowned for their reliability and precision, making them an ideal choice for high-volume automotive production. With options for multi-spindle and multi-way operations, these machines machines significantly enhance productivity. Additionally, the incorporation of various automation levels reduces cycle time, while quick change setup ensures seamless and user-friendly changeovers. Precihole has a proven track record of providing deep hole drilling solutions for a wide range of automotive components, including rackbars, pinion shafts, cylinder heads, engine blocks, and more.

QuickTECH machines are specifically designed to handle the demanding requirements of automotive component production, delivering precision and versatility for complex machining operations. QuickTECH mill/turn centers excel in tasks such as milling, turning, drilling, and tapping, allowing for the efficient production of automotive parts with exceptional accuracy. With their multi-spindle and multi-axis capabilities, these machines boost productivity and reduce cycle times, making them ideal for high-volume production. QuickTECH machines are widely utilized in the production of engine components, transmission parts, chassis components, and other critical automotive parts.

You Ji advanced vertical turning centers are specifically designed to handle the demands of automotive component production. You Ji machines are ideal for machining engine blocks, crankshafts, transmission components, and other critical automotive parts. With their robust construction and high rigidity, You Ji VTLs deliver superior stability and accuracy, ensuring the production of high-quality components. These machines offer flexibility in tooling options and can handle both small and large workpieces. By utilizing You Ji vertical turning centers, automotive manufacturers can achieve enhanced productivity, reduced cycle times, and superior machining precision, contributing to the overall success and competitiveness of the automotive industry.

AccuteX wire EDM machines are cruicial in the automotive industry for mold and die making, tool and die maintenance, gear manufacturing, fuel injection components, and the production of turbines and engine components. These machines enable precise machining of intricate shapes and details required for critical automotive parts, ensuring optimal performance, reliability, and safety of vehicles. With high accuracy and tight tolerances, AccuteX EDM technology excels in producing complex gear profiles, restoring tooling elements, manufacturing fuel injection components, and shaping engine parts. When it comes to automotive manufacturing, AccuteX EDM machines play a vital role in delivering high-quality, precise components for optimal performance and safety.

Johnford CNC machines are essential equipment used in the automotive manufacturing industry. These machines are specifically designed to handle large-scale components and perform precision machining operations required in automotive production. Bridge mills are utilized for milling, drilling, and contouring tasks on large automotive parts, such as engine blocks and chassis components. Boring mills are employed to create precise bores and holes in engine cylinders, transmission cases, and other critical components. Large lathes are used for turning operations, shaping cylindrical parts like shafts and axles with high accuracy. The use of Johnford machines ensures the production of quality automotive components that meet stringent industry standards for performance and reliability.

LICO CNC screw machines are specifically designed to efficiently produce high-precision automotive components. These machines excel in tasks such as turning, threading, and complex machining operations required for the production of various automotive parts like engine valves, pistons, connectors, and fittings. With their capability to handle a wide range of materials and intricate designs, LICO CNC screw machines ensure excellent accuracy, tight tolerances, and rapid production. By leveraging LICO CNC screw machines, automotive manufacturers can achieve enhanced productivity, superior quality, and cost-efficiency in the production of critical components for vehicles, contributing to the overall success and competitiveness of the automotive industry.

Nexturn Swiss lathes are essential tools in the automotive manufacturing industry, offering exceptional precision and versatility. These advanced machines are specifically designed to handle the complex machining requirements of automotive components. Nexturn Swiss lathes excel in tasks such as turning, milling, drilling, and thread cutting, allowing for the production of high-quality parts like engine shafts, connectors, and precision screws. With their ability to handle various materials and intricate designs, Nexturn Swiss lathes ensure tight tolerances, superior surface finishes, and efficient production. By leveraging Nexturn Swiss lathes, automotive manufacturers can achieve enhanced productivity, accelerated turnaround times, and superior quality in the manufacturing of critical components.

Ocean Technologies’ advanced machines are specifically designed to create small, high-precision holes in automotive components. Ocean Technologies small hole drilling EDM machines are widely used in the production of fuel injection nozzles, injector parts, and other critical engine components that require tight tolerances and exceptional accuracy. With their capability to handle a wide range of materials and complex geometries, these machines ensure optimal performance, reliability, and fuel efficiency. By utilizing Ocean Technologies small hole drilling EDM machines, automotive manufacturers can achieve superior quality, cost-effectiveness, and faster production times, allowing them to strengthen their position in the competitive market.

In the automotive industry, precision and uninterrupted production are paramount. Precihole offers state-of-the-art gun drilling and BTA deep hole drilling machines specifically designed to meet these requirements. Precihole machines are renowned for their reliability and precision, making them an ideal choice for high-volume automotive production. With options for multi-spindle and multi-way operations, these machines machines significantly enhance productivity. Additionally, the incorporation of various automation levels reduces cycle time, while quick change setup ensures seamless and user-friendly changeovers. Precihole has a proven track record of providing deep hole drilling solutions for a wide range of automotive components, including rackbars, pinion shafts, cylinder heads, engine blocks, and more.

QuickTECH machines are specifically designed to handle the demanding requirements of automotive component production, delivering precision and versatility for complex machining operations. QuickTECH mill/turn centers excel in tasks such as milling, turning, drilling, and tapping, allowing for the efficient production of automotive parts with exceptional accuracy. With their multi-spindle and multi-axis capabilities, these machines boost productivity and reduce cycle times, making them ideal for high-volume production. QuickTECH machines are widely utilized in the production of engine components, transmission parts, chassis components, and other critical automotive parts.

You Ji advanced vertical turning centers are specifically designed to handle the demands of automotive component production. You Ji machines are ideal for machining engine blocks, crankshafts, transmission components, and other critical automotive parts. With their robust construction and high rigidity, You Ji VTLs deliver superior stability and accuracy, ensuring the production of high-quality components. These machines offer flexibility in tooling options and can handle both small and large workpieces. By utilizing You Ji vertical turning centers, automotive manufacturers can achieve enhanced productivity, reduced cycle times, and superior machining precision, contributing to the overall success and competitiveness of the automotive industry.

Applications

Engines & Engine Components

- Engine blocks

- Cylinder heads

- Pistons

- Connecting rods

- Crankshafts

- Camshafts

- Valves

- Timing gears & chains

Transmissions & Drivetrain Components

- Transmission housings

- Gears

- Shafts

- Clutches

- Differential assemblies

- Axles

- CV joints

Chassis & Suspension Components

- Frame rails

- Crossmembers

- Control arms

- Steering knuckles

- Ball joints

- Sway bars

- Leaf springs

- Coil springs

- Shock absorbers

Other Components

- Suspension components

- Chassis frames

- Wheels

- Bearings & bushings

- Hinges, clamps, & brackets

- More

Exhaust systems

- Exhaust manifolds

- Exhaust pipes

- Catalytic converters

- Mufflers

- Tailpipes

Fuel system components

- Fuel tanks

- Fuel pumps

- Fuel injectors

Brake System Components

- Brake calipers

- Brake rotors

- Brake drums

- Brake pads

The Absolute Advantage:

- Unmatched Expertise: With years of experience in the automotive industry, we have in-depth knowledge of the challenges you face. Our team of experts is dedicated to understanding your specific needs and providing customized solutions that drive your success.

- Cutting-Edge Technology: We stay at the forefront of technological advancements in the automotive industry. By partnering with us, you gain access to the latest innovations that enhance your manufacturing capabilities and give you a competitive edge.

- Superior Quality & Reliability: At Absolute Machine Tools, quality is our top priority. We partner with renowned manufacturers known for their precision and reliability. Our machines undergo rigorous testing to ensure they meet the highest standards, guaranteeing exceptional performance and longevity.

- Comprehensive Support & Training: We don’t just provide machinery; we provide complete support and training to ensure your team is fully equipped to leverage our solutions effectively. Our experienced technicians are always available to provide assistance, training, and ongoing support, ensuring optimal performance and minimal downtime.

Partner with Absolute Machine Tools Today

When it comes to automotive manufacturing excellence, Absolute Machine Tools is the partner you can trust. We are committed to helping you achieve operational efficiency, maximize productivity, and stay ahead in the competitive automotive industry. Complete the form below to contact us today to learn more about our cutting-edge machinery and customized solutions tailored to your unique needs. Together, let’s drive success in the automotive manufacturing landscape.