Shimada Kitako B6 Series – 6 Spindle Automatic Lathes

High-Speed 6-Spindle Automatic CNC Lathes for Continuous Bar Production

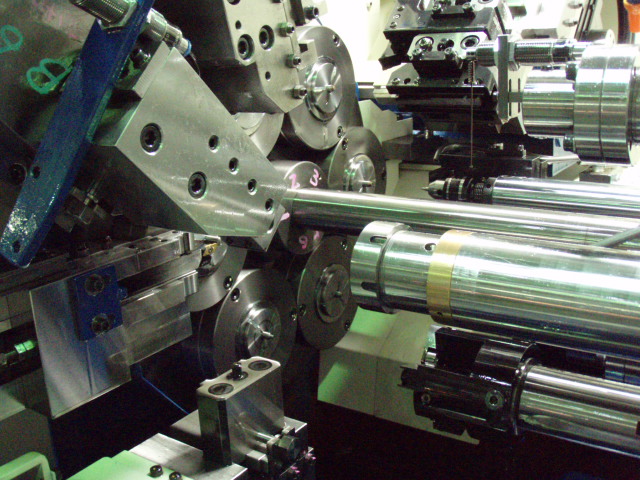

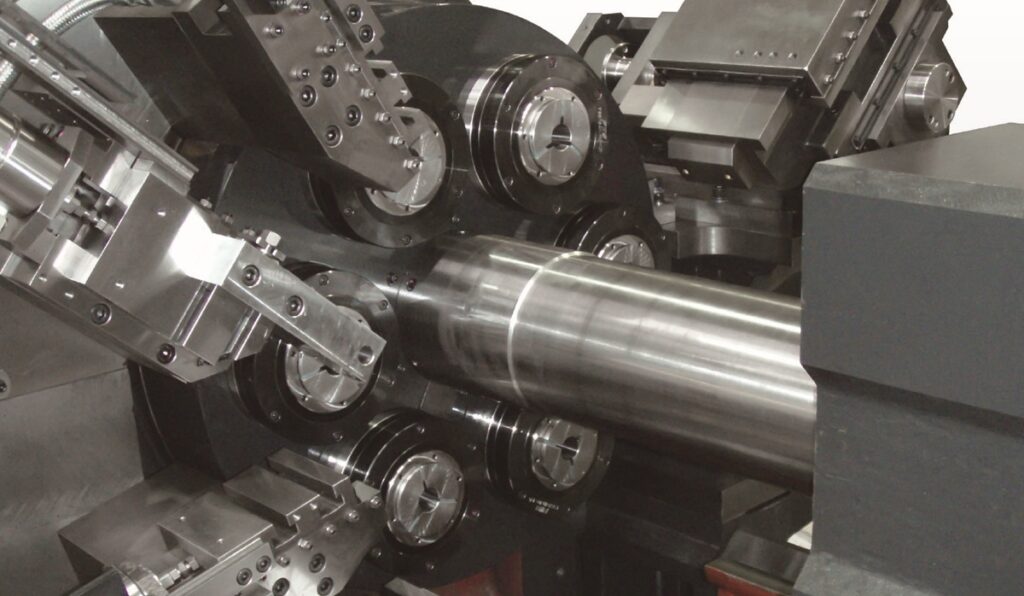

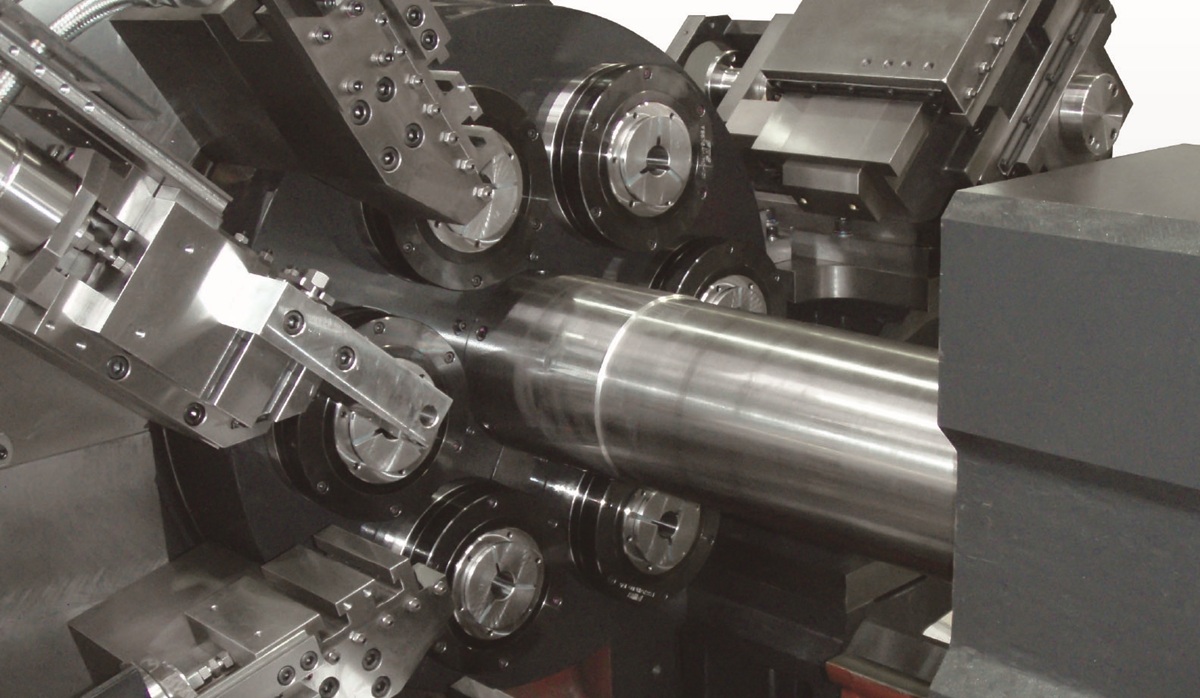

The Shimada Kitako B6 Series consists of four camless, 6-spindle horizontal automatic lathes designed for continuous, high-output bar work. Each spindle performs a different phase of the machining cycle, while the spindle carrier indexes 60° between operations — enabling fully synchronized, uninterrupted production with extremely low idle time. The combination of multi-spindle efficiency and CNC-controlled slides gives manufacturers both high-volume output and modern process flexibility.

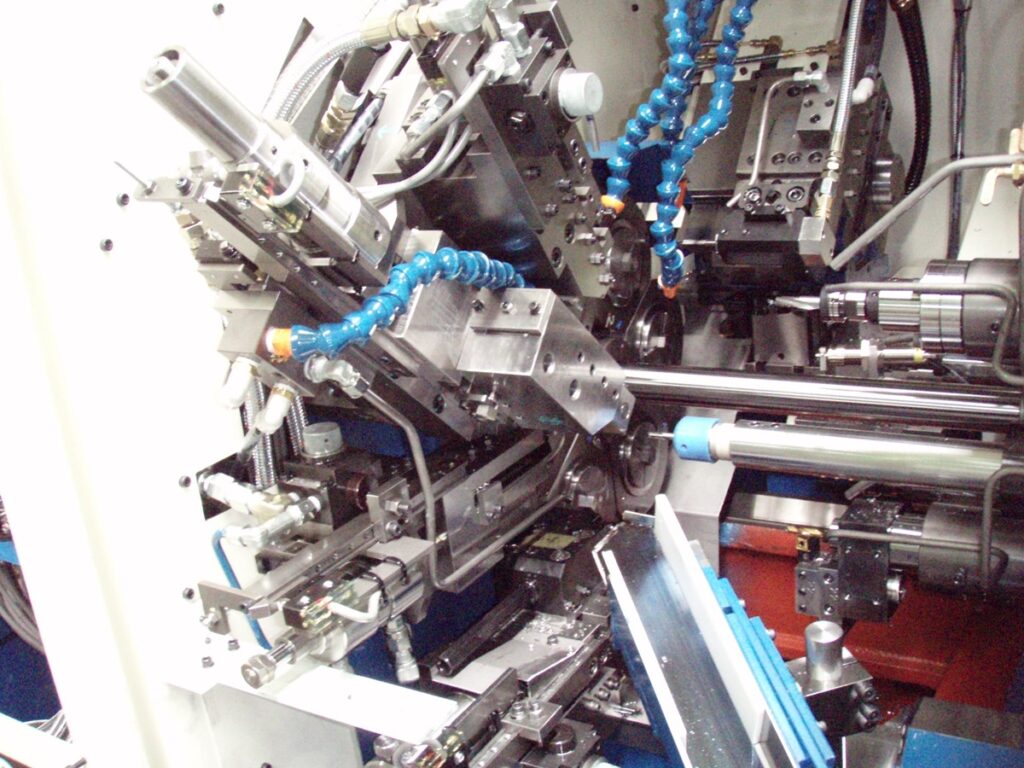

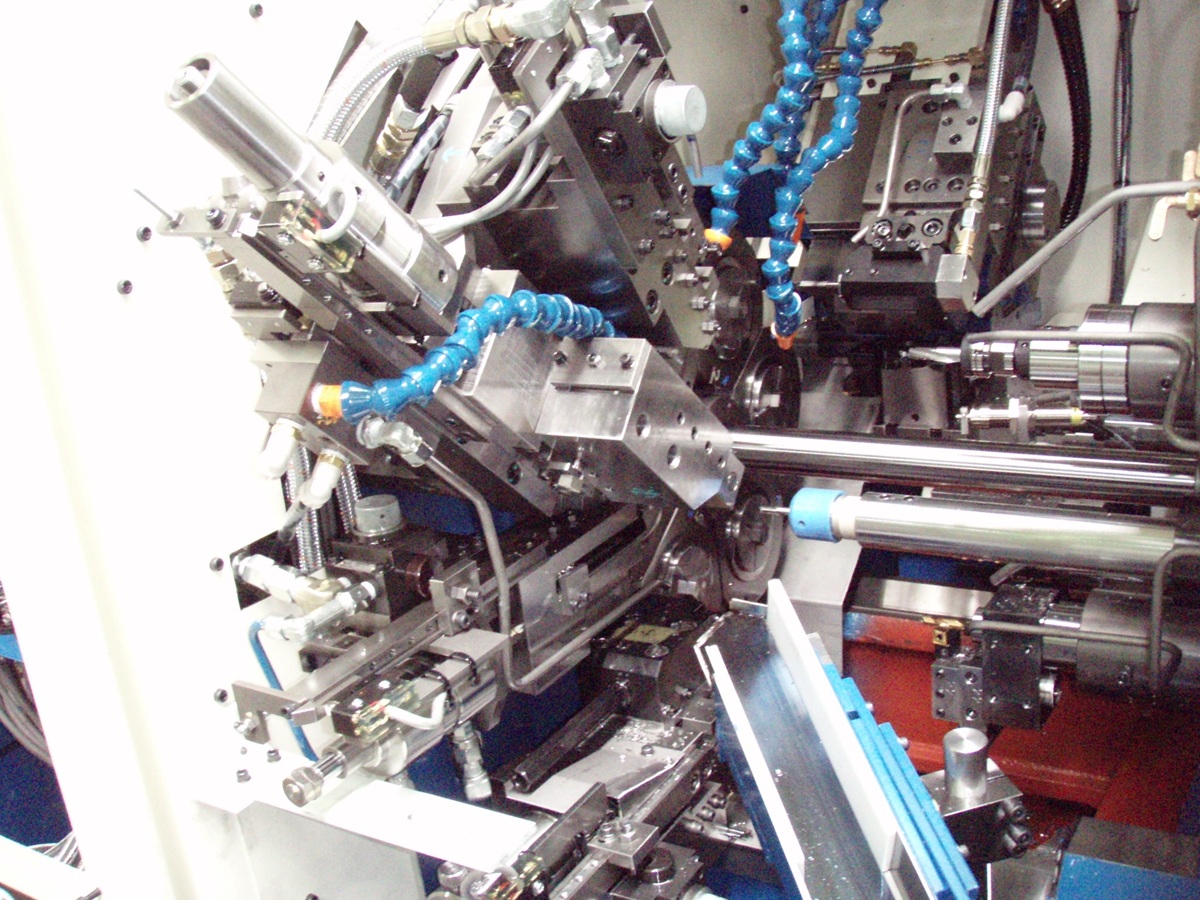

Each model supports up to three CNC 2-axis slides, providing synchronized 6-axis capability for contouring, drilling, grooving, and cutoff operations. The B6 Series merges the speed of traditional screw machines with the precision, programmability, and rapid setup advantages of CNC. Standard equipment includes an IEMCA or Pietro Cucchi compact automatic bar feeder, remnant ejection, and quick-change tooling, making the B6 platform suited for just-in-time manufacturing and lights-out automation.

Key Features

- 6-Spindle Horizontal Configuration

Each spindle completes a different phase of machining while the carrier indexes 60°. - Camless Hydraulic Drive (Optional NC Drive)

Provides smooth, stable motion with reduced mechanical complexity. - Up to Three CNC 2-Axis Slides

Allows synchronized 6-axis functionality for advanced cutting sequences. - Wide Bar Capacity Range

Models cover 4 mm to 32 mm diameters depending on application. - High-Speed Spindle Performance

3,000–4,000 rpm depending on model. - Standard Automatic Bar Feeder

Choice of IEMCA or Pietro Cucchi compact side-mounted feeder. - Remnant Ejection System

Enables continuous, unattended bar processing. - Quick-Change Tooling System

Minimizes downtime between part changeovers. - Uniform Machine Layout

All models share 9.84″ (250 mm) stroke and 4.72″ (120 mm) max feed length.

Available Models in the B6 Series

- B6-16 – Small-Diameter High-Speed Model

Designed for 4–16 mm bar stock, the B6-16 provides fast, precise multi-spindle turning ideal for miniature and small-diameter components. - B6-27 – Medium-Diameter Versatile Model

Built for 10–27 mm bar stock, the B6-27 offers a balanced blend of speed and rigidity for general industrial, hydraulic, and automotive parts. - B6-32 – Large-Diameter Heavy-Duty Model

Engineered for 14–32 mm bar stock, the B6-32 delivers stable high-volume machining for larger fittings, shafts, valves and industrial hardware.

The Shimada Kitako B6 Series delivers the unmatched throughput of a 6-spindle automatic with the flexibility and precision of CNC-controlled slides. Whether producing small medical components or larger industrial hardware, Absolute Machine Tools can help configure the ideal B6 model and automation package for your application.

Specifications

| Item / Model |

B6-164

Request a Quote |

B6-27

Request a Quote |

B6-32

Request a Quote |

|---|---|---|---|

|

No. of Spindles |

6 |

6 |

6 |

|

Bearing Diameter |

∅2.17″ (55 mm) |

2.76″ (70 mm) |

2.76″ (70 mm) |

|

Spindle RPM |

4000 RPM |

3000 RPM |

3000 RPM |

|

Max Bar Diameter |

∅0.157″ – 0.692″ (∅4 – 16 mm) |

∅0.393″ – 1.06″ (∅10 – 27 mm) |

∅0.551″ – 1.26″ (∅14 – 32 mm) |

|

Max Feed Length |

4.72″ (120 mm) |

4.72″ (120 mm) |

4.72″ (120 mm) |

|

Max Bar Length |

10.83′ (3.3M) (14.11′ or 4.3M opt.) |

10.83′ (3.3M) (14.11′ or 4.3M opt.) |

10.83′ (3.3M) (14.11′ or 4.3M opt.) |

|

Drive System |

Camless Hydraulic (NC Drive opt.) |

Camless Hydraulic (NC Drive opt.) |

Camless Hydraulic (NC Drive opt.) |

|

Tool Diameter |

∅2.17″ (55 mm) |

∅2.17″ (55 mm) |

∅2.17″ (55 mm) |

|

Stroke |

9.84″ (250 mm) |

9.84″ (250 mm) |

9.84″ (250 mm) |

|

Machine Weight w/2 NC Slides |

10,582 lbs. (4800 kg) |

11,464 lbs. (5200 kg) |

12,346 lbs. (5600 kg) |