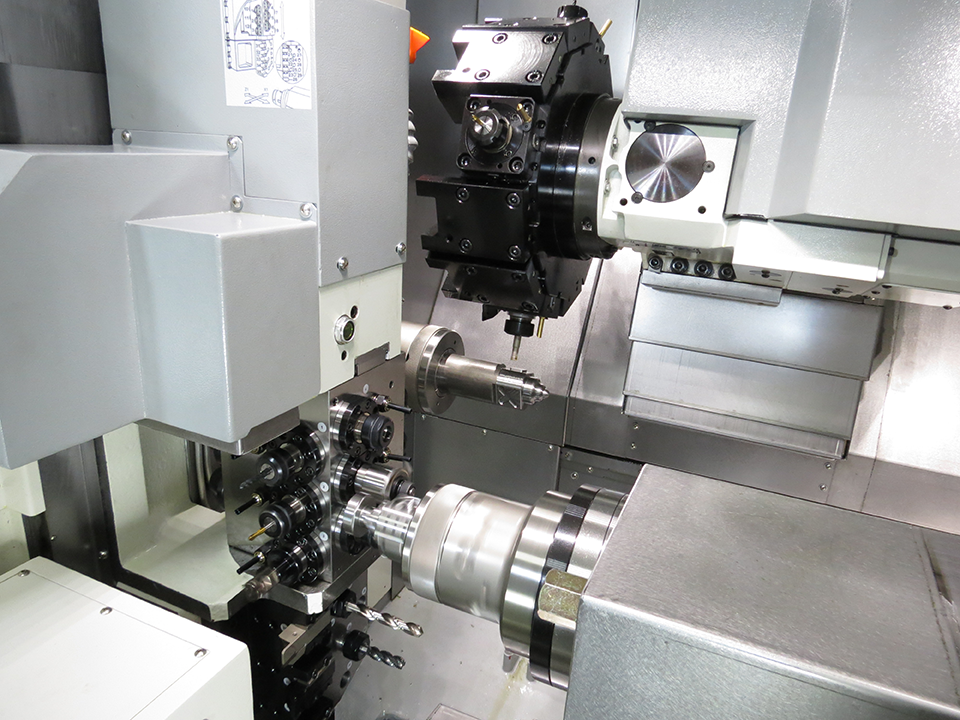

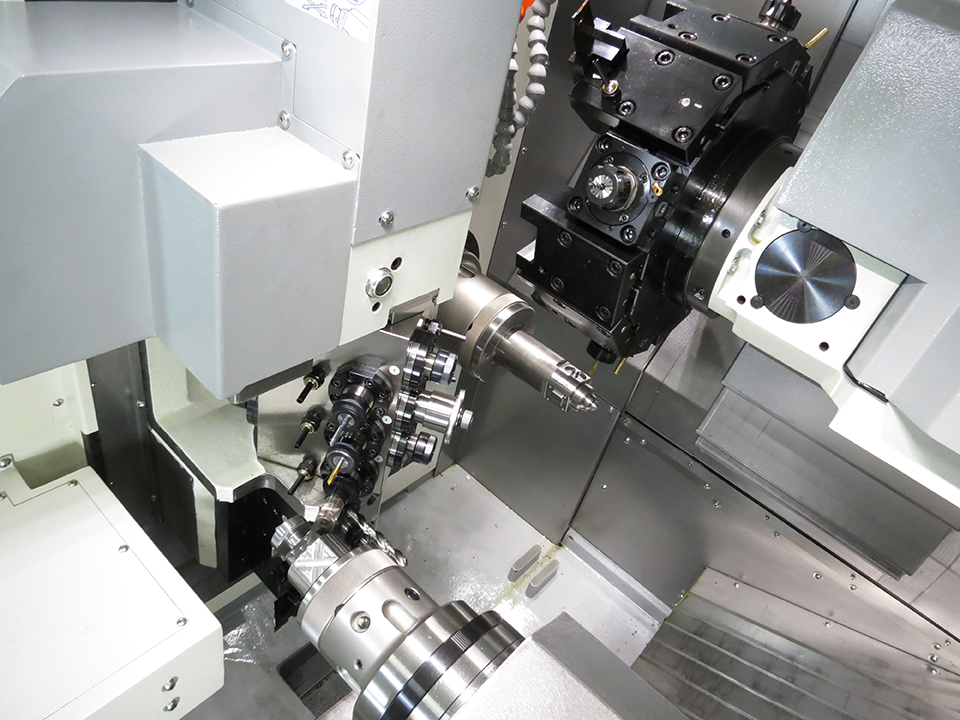

Quicktech T8 Series – T8 Compact (2-Axis), T8 Mill (3-Axis) & T8 Twin Y (6-Axis) Mill-Turn Centers with Turrets

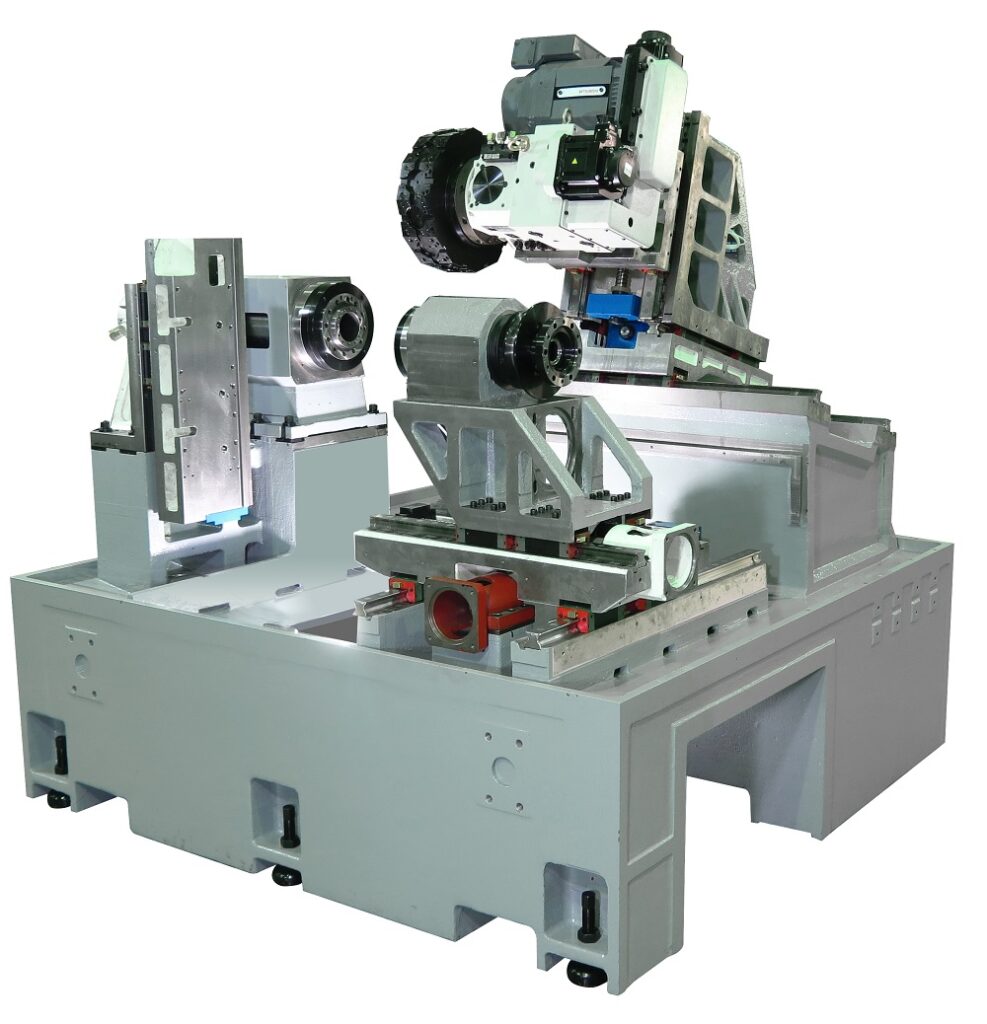

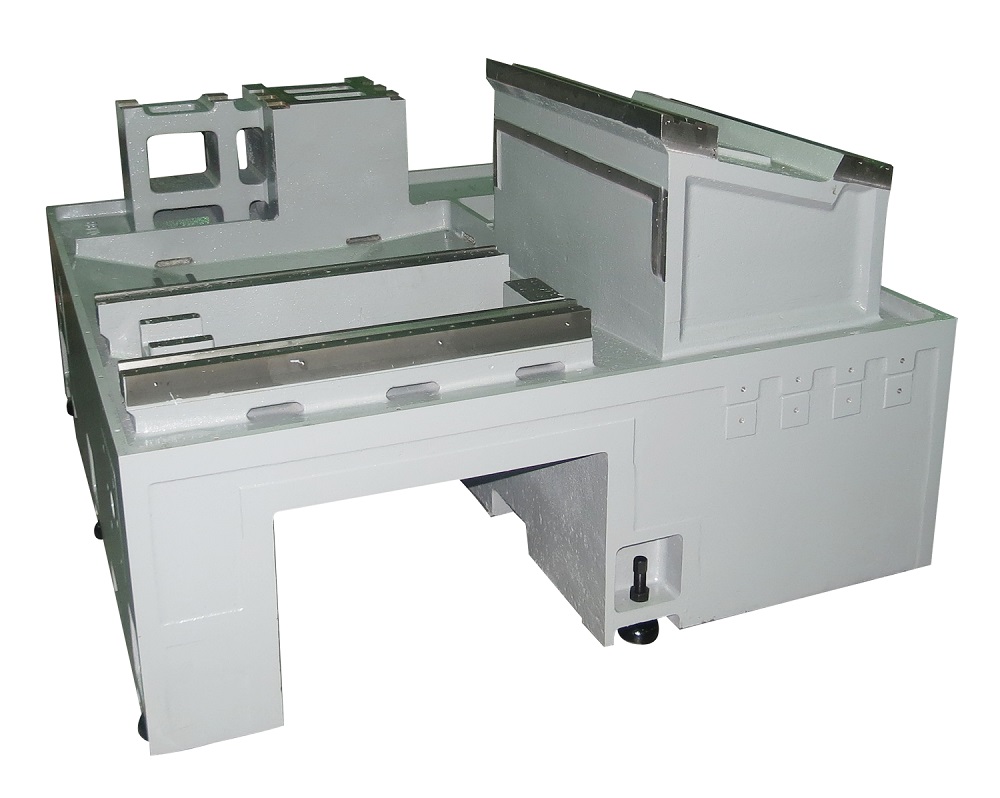

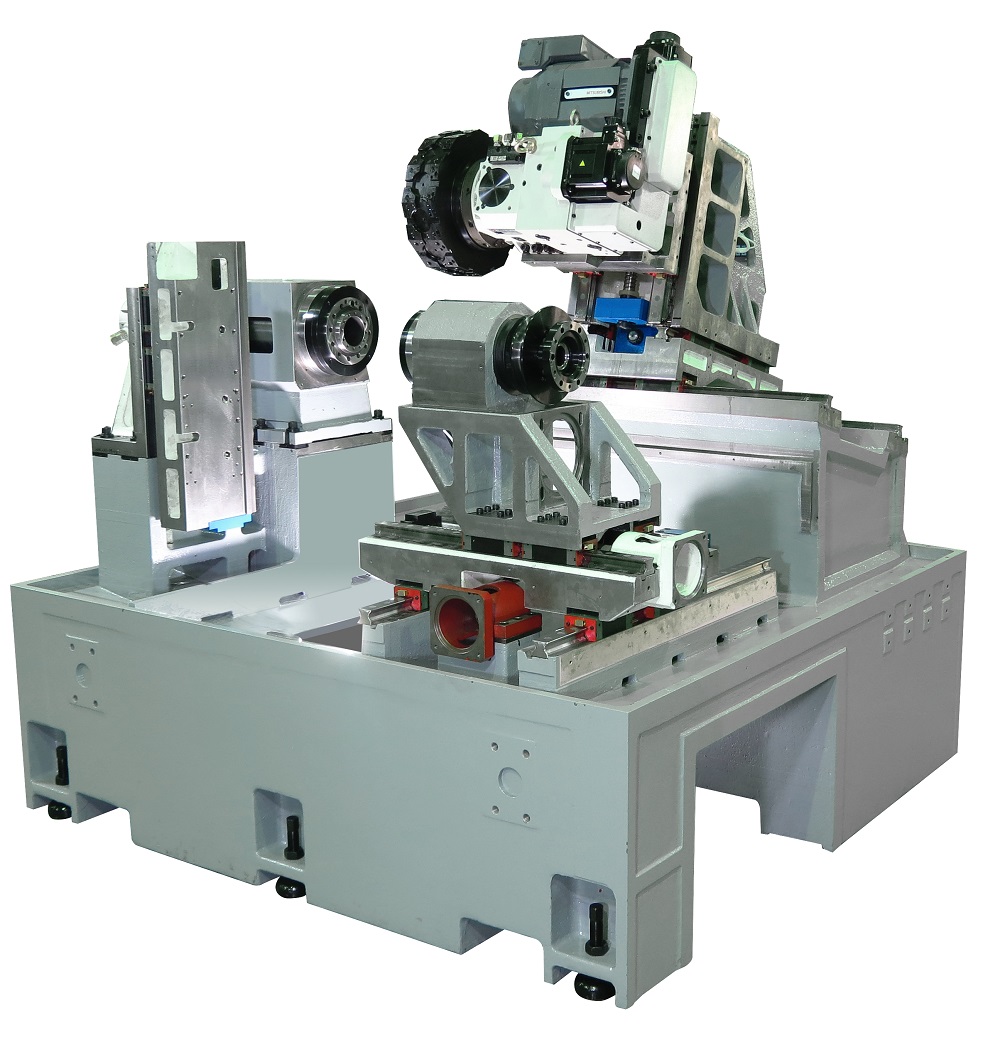

The QuickTECH T8 Series includes the T8 Compact (2-axis), T8 Mill (3-axis), and T8 Twin Y (6-axis) CNC mill-turn centers — engineered for manufacturers who demand flexibility, precision, and reliability in a compact footprint. Each model is cast from high-quality Meehanite iron for maximum rigidity and vibration damping, ensuring consistent cutting performance and extended tool life. With advanced Mitsubishi or Fanuc controls and a range of configurations, the T8 Series delivers outstanding value for industries such as automotive, medical, defense, and general machining, where consistent accuracy and efficient throughput are essential.

Comparable to Haas, Doosan, DMG Mori, and Mazak machines, the T8 Series provides exceptional precision, powerful spindle performance, and a lower overall cost of ownership.

Key Features

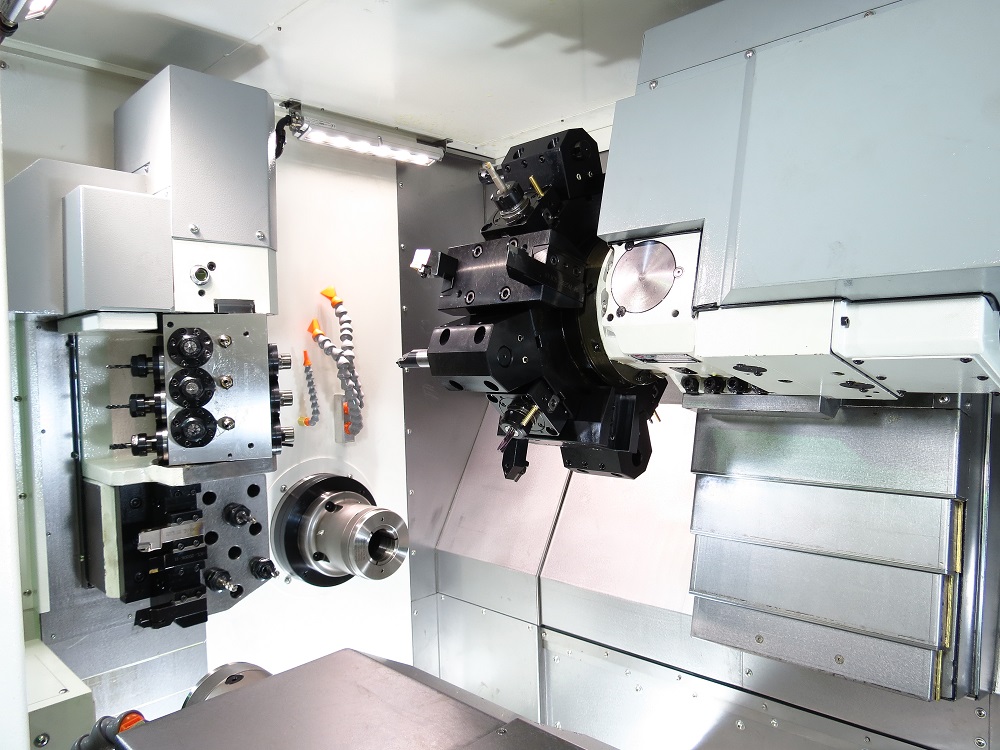

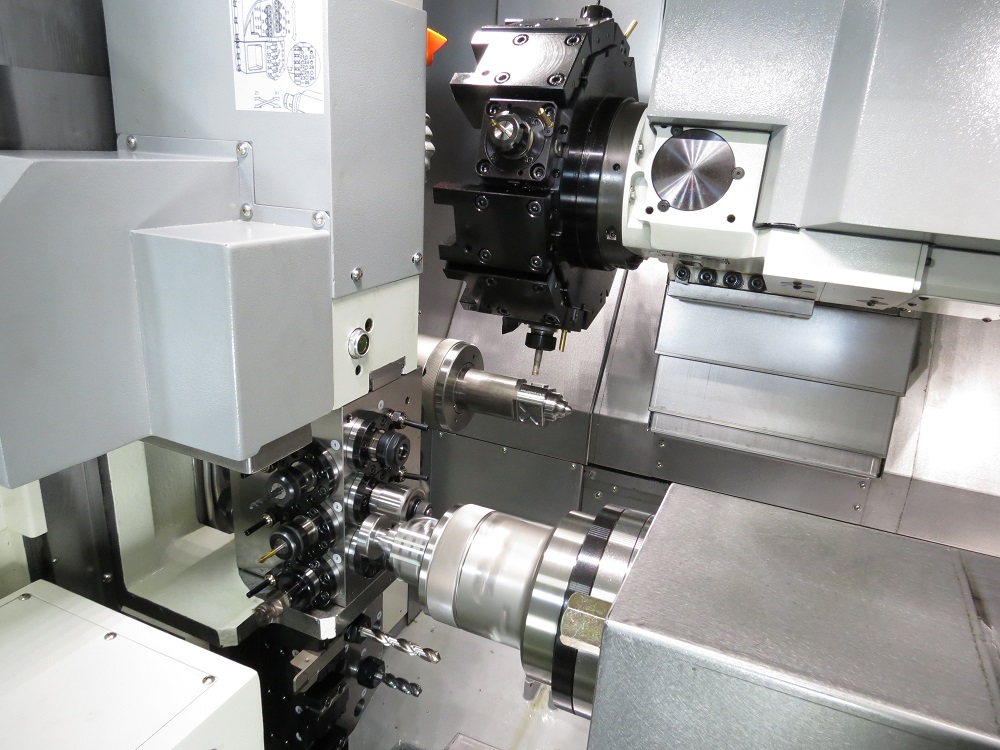

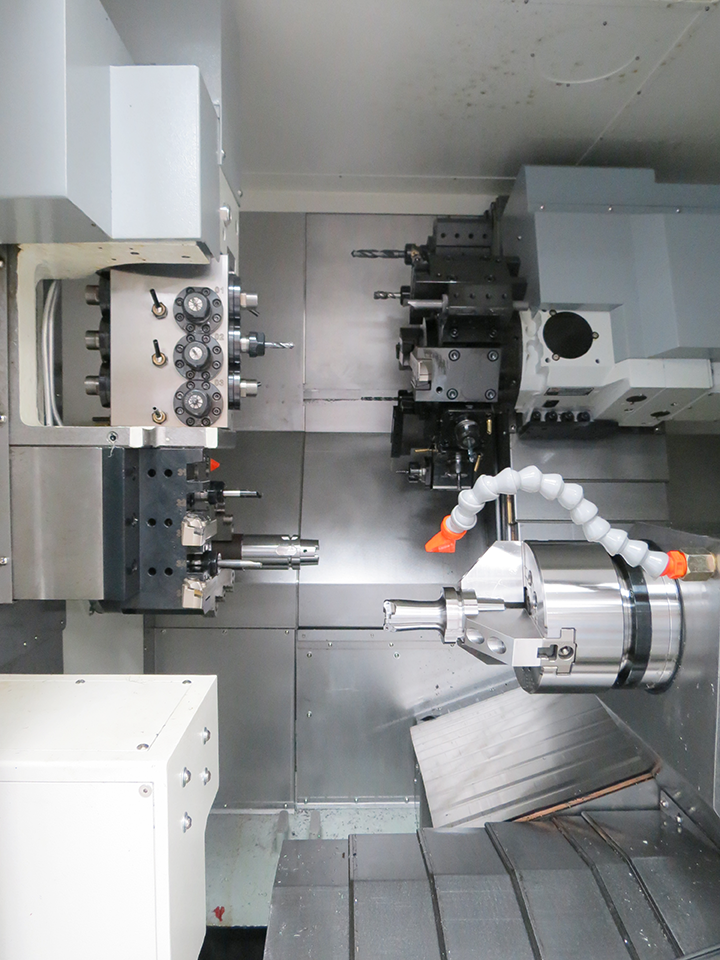

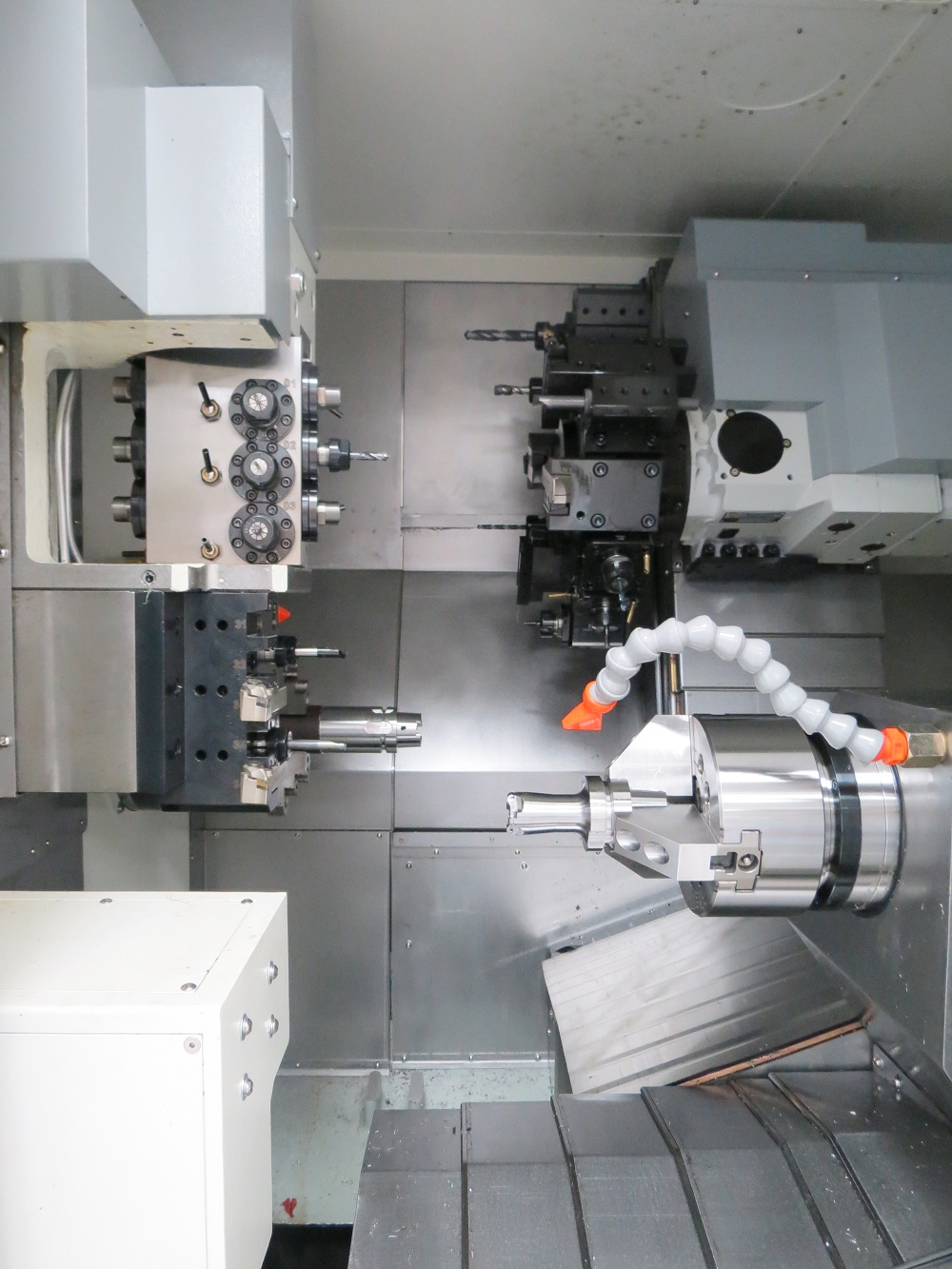

- Powerful Spindle System: 20HP main spindle with 2.5″ (65mm) bar capacity for smooth and accurate metal removal. The T8 Twin Y adds a synchronized sub-spindle (7.5HP) for simultaneous front- and back-working.

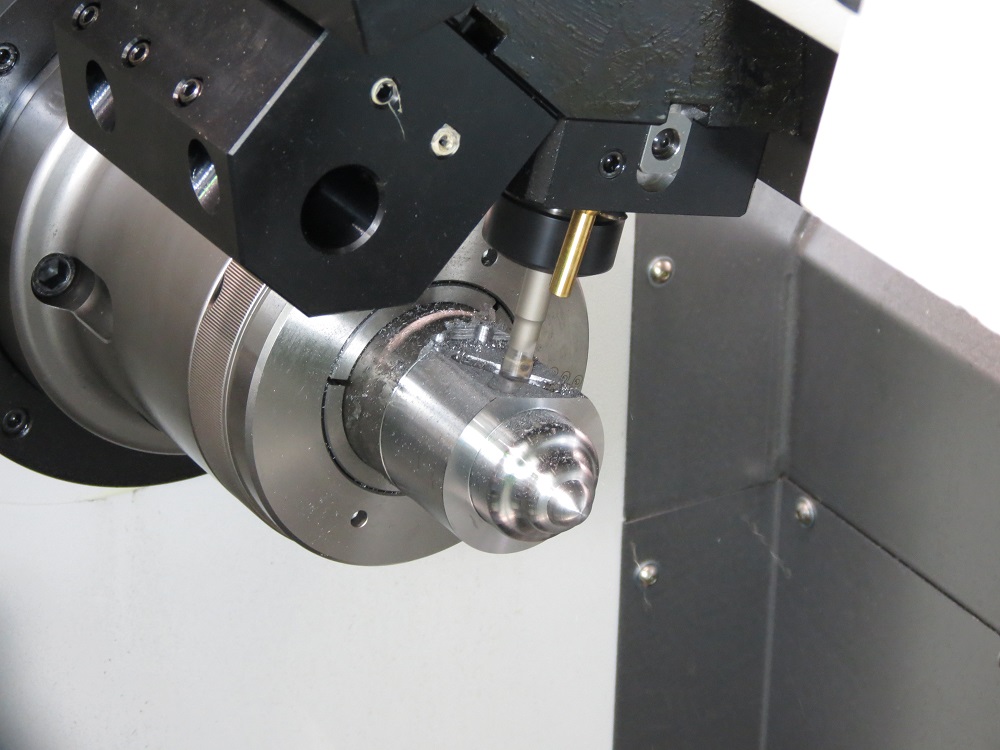

- Rigid Construction: One-piece 75° slant-bed Meehanite casting provides superior vibration control and cutting rigidity across all models.

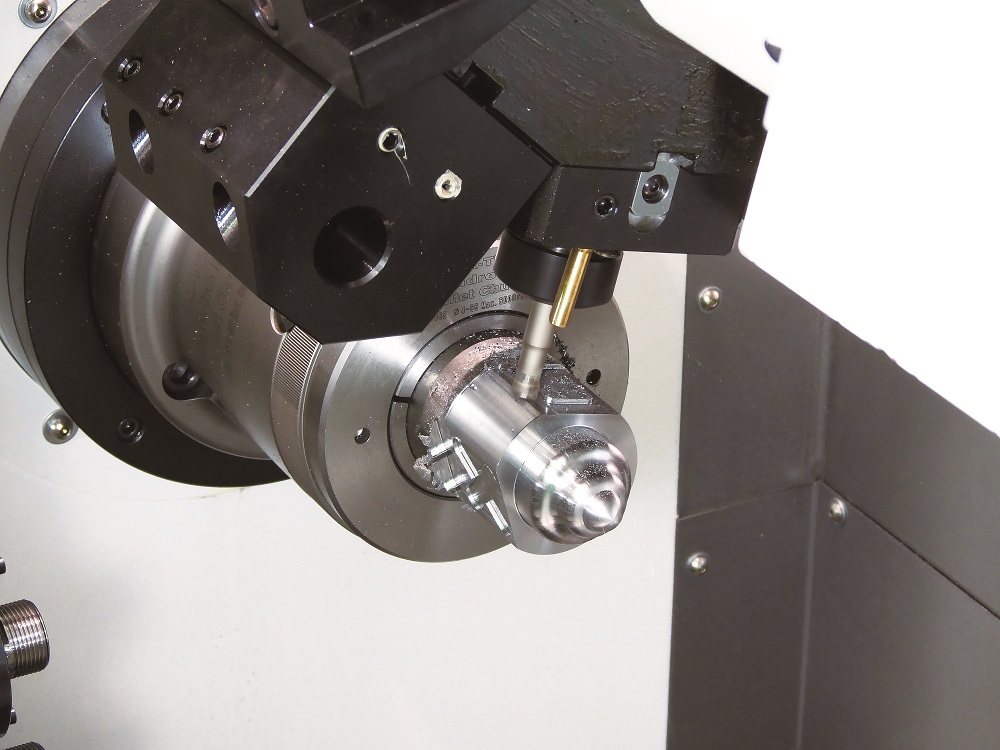

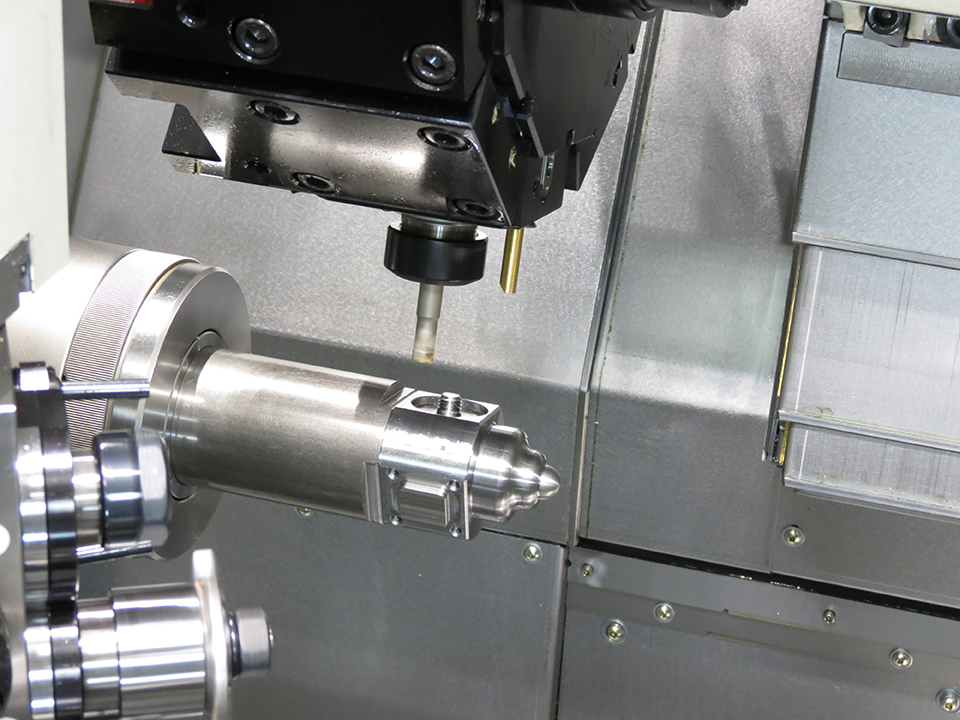

- Precision Motion System: 35mm Hiwin roller-type linear guideways and 32mm pre-tensioned double-anchored ballscrews ensure accuracy to ±0.0002″ and repeatability to ±0.00015″.

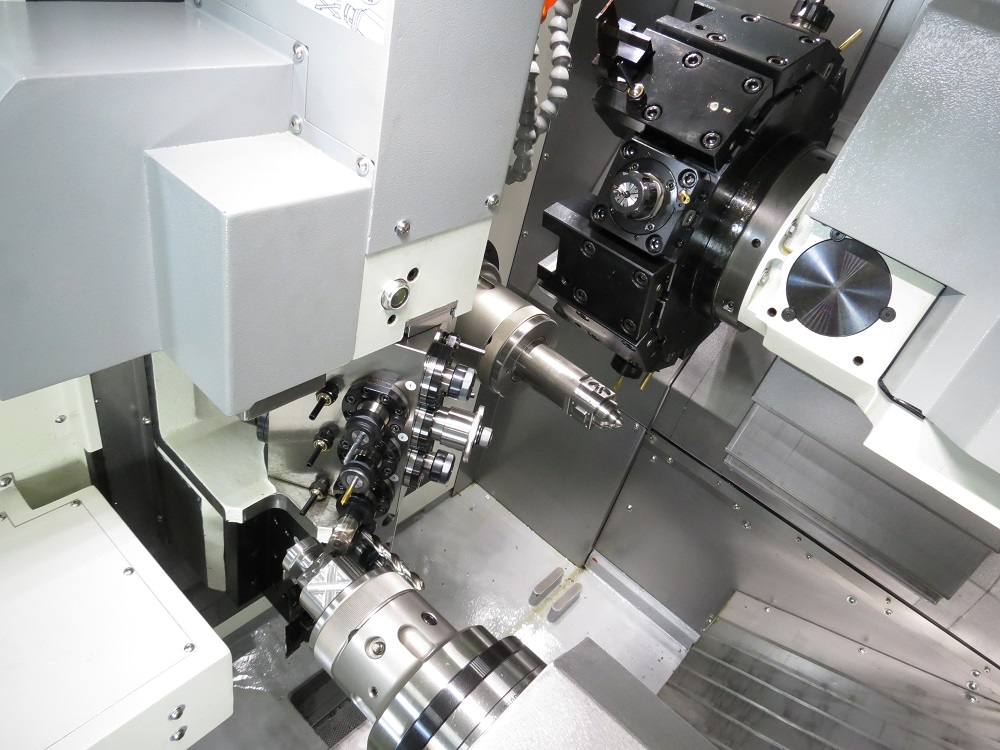

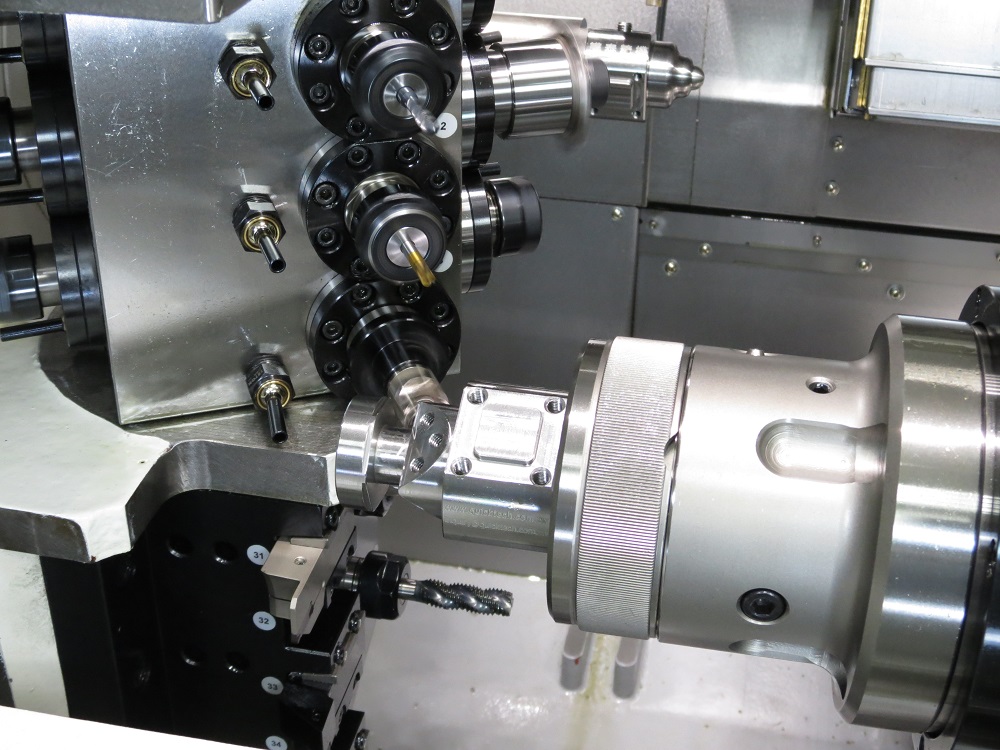

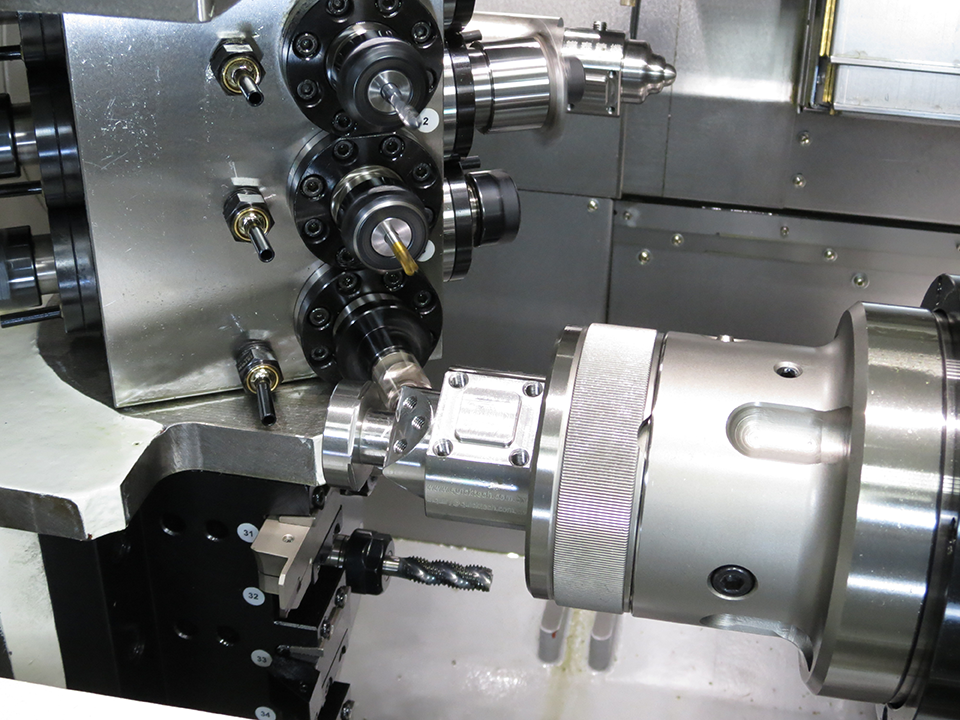

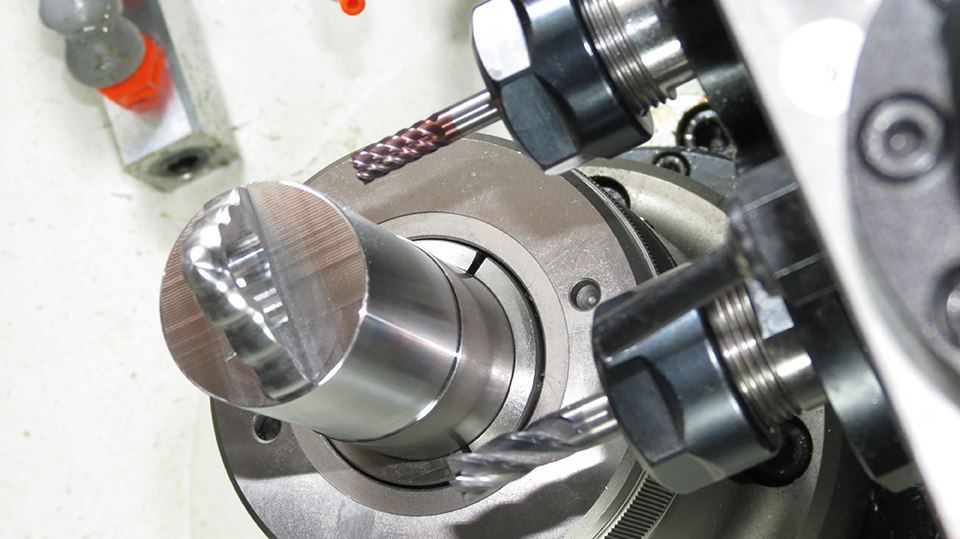

- Advanced Turret Tooling Systems:

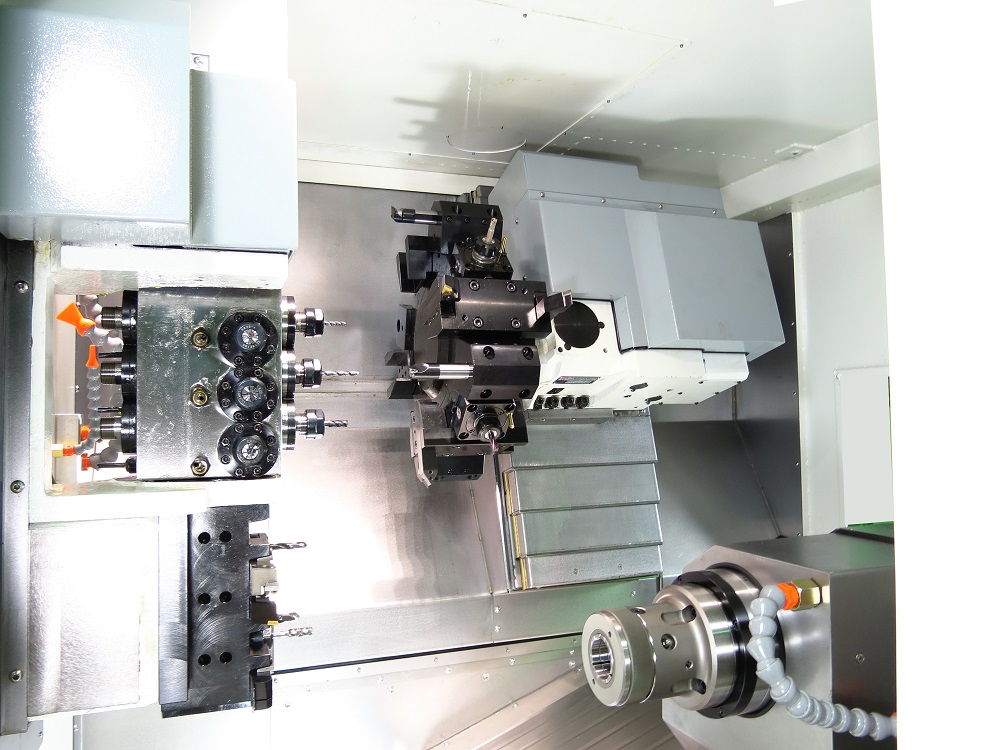

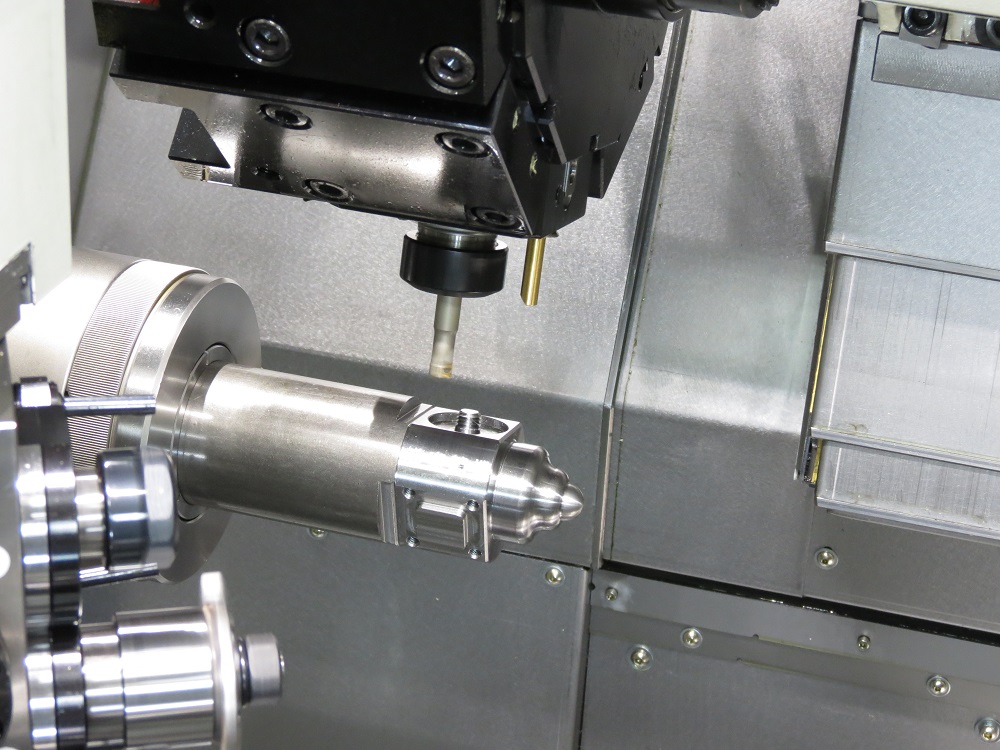

- T8 Compact: 12-station BMT-55 servo turret for efficient 2-axis turning and fast indexing.

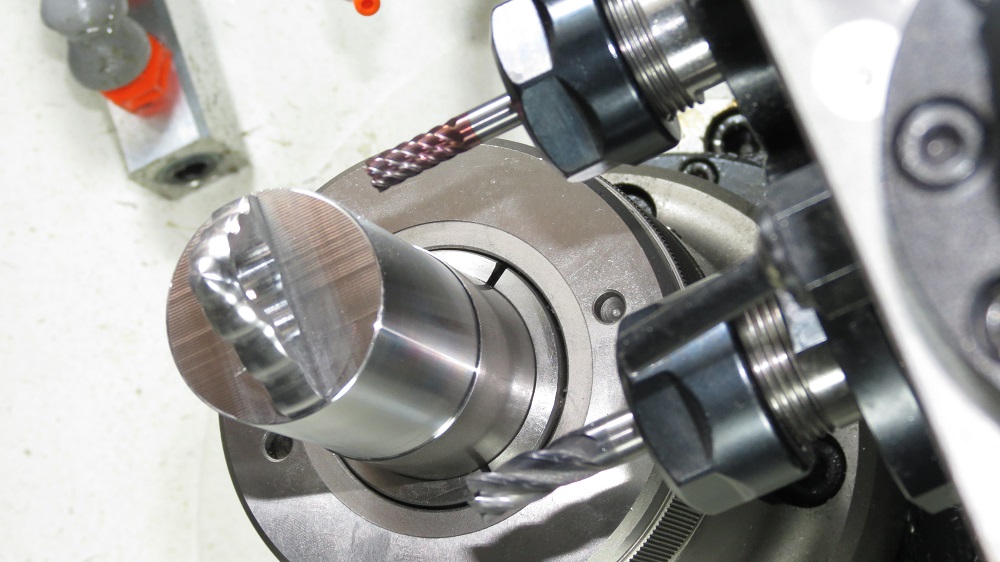

- T8 Mill: 12-station live BMT-55 turret with 5HP milling motor, 4000 RPM live tooling, and rigid tapping capability.

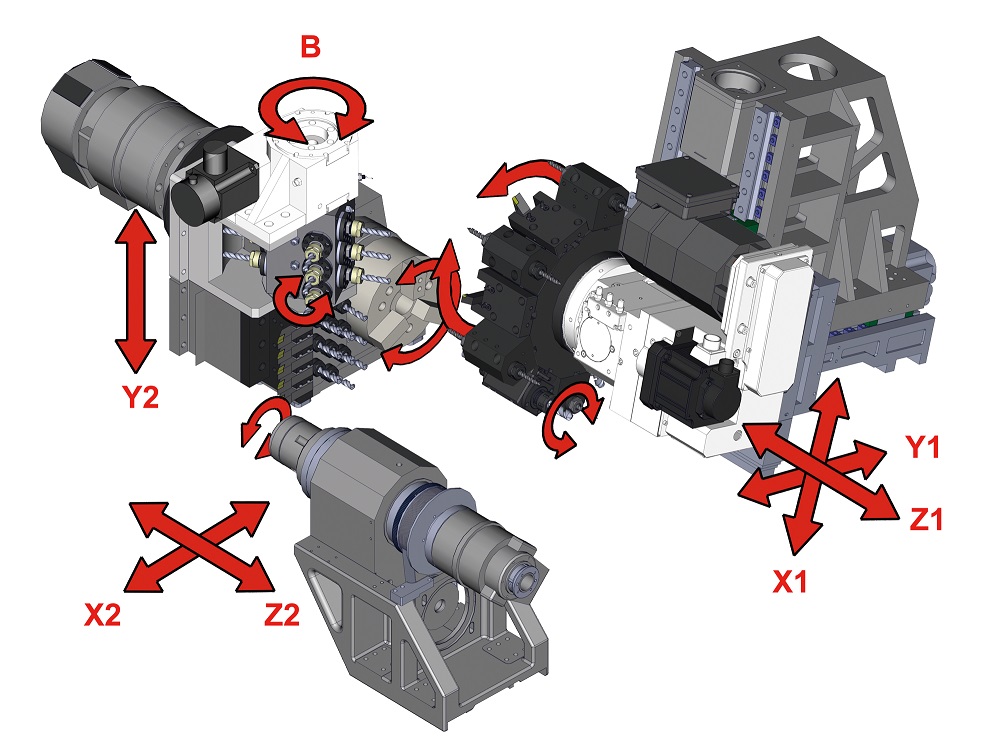

- T8 Twin Y: 12-station live BMT-55 turret with full linear Y-axis travel (+/-1.57″), allowing gang tooling up to 36 tools for complex milling and cross-drilling on both spindles.

- CNC Control Options: Mitsubishi M80A with 10.4″ color touchscreen, 3D solid graphics, and Navi-Lathe conversational programming (Fanuc OiT-F Plus optional).

- Integrated Automation Ready: Factory bar feeder interface and compatibility with A+ Automation robot tending packages or TRACER bar feeders for lights-out production.

- Standard Equipment: Hydraulic 3-jaw chuck, parts catcher, chip conveyor, 75 PSI coolant pump, and auto-lubrication system included for complete turnkey operation.

Specifications

| Item / Model |

T8 COMPACT

Request a Quote |

T8 MILL

Request a Quote |

T8 Twin Y

Request a Quote |

|---|---|---|---|

|

Main Spindle Capacity | |||

|

Swing over Bed |

19.7″ |

19.7″ | |

|

Swing over Cross Slide |

11.8″ |

11.8″ |

11.8″ |

|

Max Bar Working Capacity |

2.56″ (65mm) |

2.56″ (65mm) |

2.56″ (65mm) |

|

Max Turning Length |

13.8″ |

13.8″ |

13.8″ |

|

Spindle Speed Range |

4,000 RPM |

4,000 RPM |

4,000 RPM |

|

Spindle Motor |

20 HP Integral Motor |

20 HP Integral Motor |

20 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

.001° |

|

Sub-Spindle Capacity | |||

|

Max Bar Working Capacity |

1.65″ (42mm) | ||

|

Max Turning Length |

13.2″ | ||

|

Spindle Speed Range |

4,000 RPM | ||

|

Spindle Motor |

7.5 HP Integral Motor | ||

|

C-Axis Increment |

.001° | ||

|

Travel and Feed | |||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

1,181″/min. |

|

Tooling System (Main) | |||

|

Tooling Type |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

|

Number of Tools |

12 |

12 |

12 |

|

Number of Live Tool Stations |

12 |

12 | |

|

Square Shank Size |

1″ (25mm) |

1″ (25mm) |

1″ (25mm) |

|

Boring Bar Capacity |

1.25″ (25mm) |

1.25″ (25mm) |

1.25″ (25mm) |

|

Turret Index Time |

.3 Seconds / Station |

.3 Seconds / Station |

.3 Seconds / Station |

|

Live Tool Spindle Motor |

5 HP |

5 HP | |

|

Live Tool Spindle Speed |

4,000 RPM |

4,000 RPM | |

|

Tooling System (Sub) | |||

|

Tooling Type | |||

|

Number of Turning Tools | |||

|

Square Shank Size | |||

|

Boring Bar Capacity | |||

|

B-Axis | |||

|

B-Axis Index Time | |||

|

Number of Live Tools | |||

|

Live Tool Spindle Motor | |||

|

Live Tool Spindle Speed | |||

|

Live Tool Shank | |||

|

Tailstock | |||

|

Body Travel (manual) |

15.7″ |

15.7″ | |

|

Quill Travel (programmable hydraulic) |

3.15″ |

3.15″ | |

|

Quill Diameter |

2.95″ |

2.95″ | |

|

Quill Taper |

MT#4 |

MT#4 | |

|

General | |||

|

CNC Control |

Mitsubishi M80A |

Mitsubishi M80A |

Mitsubishi M80A |

|

Machine Dimensions with Chip Conveyor |

128″ x 65″ x 69″ |

128″ x 65″ x 69″ |

132″ x 65″ x 69″ |

|

Machine Weight |

12,040 lbs. |

12,500 lbs. |

12,540 lbs. |

Benefits for Metal Cutting Manufacturers

The QuickTECH T8 Series gives manufacturers a cost-effective solution for complete part machining in a single setup — reducing downtime, increasing productivity, and improving surface quality. Each model is designed to handle a wide variety of parts with superior rigidity, stability, and accuracy, making it ideal for production turning and light milling applications.

By eliminating secondary operations and reducing setups, the T8 Series improves part-to-part consistency, shortens cycle times, and provides the stability needed for ultra-fine surface finishes and tight-tolerance machining.