AccuteX DS-X Series – CNC EDM Die Sinkers

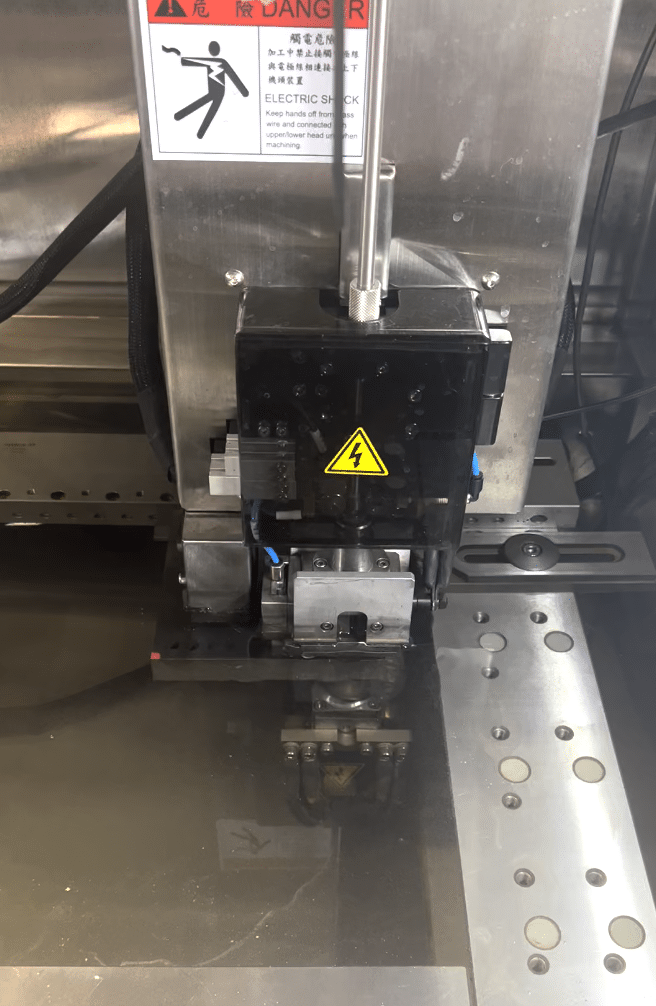

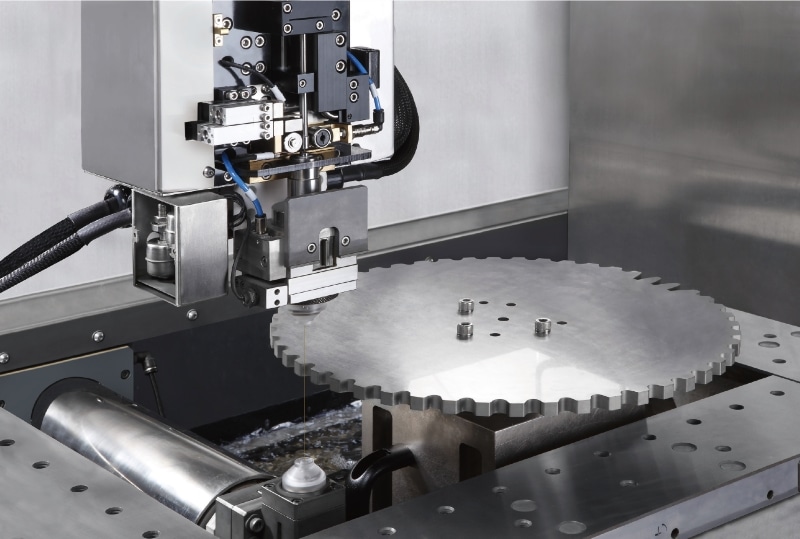

AccuteX DS-X Series are RAM type CNC EDM machines offering a full range of sizes and capabilities built with rigid heavy-duty Meehanite casting designed using Finite Element Analysis (FEA) to ensure rigidity and precision accuracy.

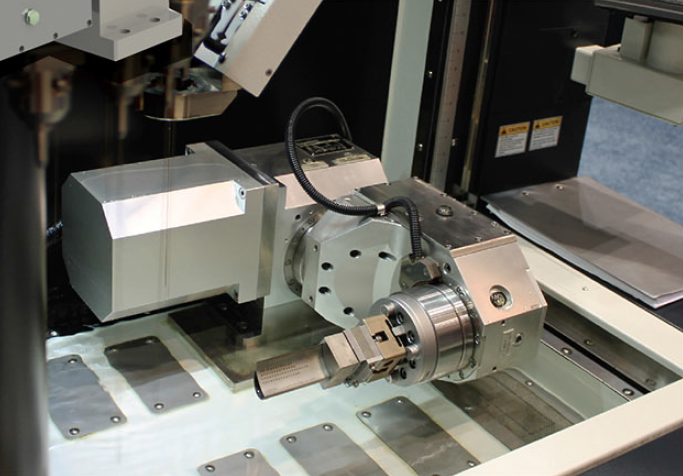

The series begins with the DS-430X moving table-type CNC die sinker machine followed by moving column type models ranging in size from DS-500X up to DS-3010X. Travels range from 400mm (16″) – 3000mm (118″) in X, 300mm (12″) – 1000mm (39″) in Y, and finally 300mm (12″) – 600mm (24″) in Z. For larger heavier workpieces, or to burn two large workpieces simultaneously, the AccuteX DS-2H twin head design is also available. The DS-X twin head (twin ram) series includes models ranging from DS-1510X-2H up to DS-3010X-2H and can be built in a twin head (2H) or single head design, allowing for maximum production and versatility on the big jobs.

AccuteX EDM also offers the DS-ZNC series of manual die sinkers. All ZNC model die sinking EDM machines offer an NC-controlled X, Y axis option that allows for a wide range of operations only available on full 3D machines. Multiple cavity positioning, X or Y axis side machining, auto centering, fuzzy auto set parameter setting and X,Y axis orbiting using the COC-280 integrated orbit head make the AccuteX DS-NC series boost cost effectiveness and productivity.

Specifications

| Item / Model |

DS-430X (Moving-Table)

Request a Quote |

DS-500X (Moving-Column)

Request a Quote |

DS-750X

Request a Quote |

DS-1060X

Request a Quote |

DS-1270X

Request a Quote |

DS-1510X

Request a Quote |

DS-1880X

Request a Quote |

DS-2210X

Request a Quote |

DS-2610X

Request a Quote |

DS-3010X

Request a Quote |

|---|---|---|---|---|---|---|---|---|---|---|

|

X-Axis (mm) |

400 |

500 |

700 |

1000 |

1200 |

1500 |

1800 |

2200 |

2600 |

3000 |

|

Y-Axis (mm) |

300 |

400 |

500 |

600 |

700 |

1000 |

800 |

1000 |

1000 |

1000 |

|

Z-Axis (mm) |

300 |

450 |

500 |

500 |

500 |

600 |

600 |

600 |

600 |

600 |

|

Max Workpiece Dimension (WxD mm) |

920 x 505 |

1020 x 710 |

1370 x 850 |

1670 x 990 |

1860 x 1120 |

2070 x 1570 |

2420 x 1220 |

2710 x 1580 |

3290 x 1690 |

3915 x 1580 |

|

Max Tank Filling Height (mm) |

215 |

355 |

355 |

460 |

460 |

585 |

505 |

605 |

585 |

605 |

|

Distance between Chuck & Table (mm) |

150 – 450 |

130 – 480 |

80 – 580 |

260 – 760 |

395 – 895 |

580 – 1180 |

305 – 905 |

575 – 1175 |

560 – 1160 |

560 – 1160 |

|

Max Workpiece Weight (kg) |

550 |

2300 |

3000 |

4500 |

5000 |

11000 |

7000 |

9500 |

10000 |

16000 |

|

Max Electrode Weight (kg) |

120 |

200 |

250 |

350 |

400 |

500 |

500 |

500 |

500 |

500 |

|

Table Size (WxD mm) |

650 x 350 |

850 x 450 |

1000 x 600 |

1250 x 750 |

1350 x 820 |

1580 x 1100 |

1850 x 1000 |

2250 x 1100 |

2700 x 1100 |

3100 x 1100 |

|

Machine Weight (kg) |

1200 |

3000 |

4500 |

5500 |

6500 |

14700 |

9000 |

13500 |

16500 |

19500 |

|

Tank Capacity (L) |

380 |

850 |

1090 |

1610 |

1875 |

3410 |

2715 |

4035 |

5400 |

5580 |

|

Filter Density (µ) |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

Filter Elements (pcs) |

3 |

6 |

6 |

6 |

6 |

6 |

8 |

8 |

8 |

8 |

|

Max Working Current (A) |

60 |

60 |

60 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

|

Overall Power Consumption (KVA) |

6 |

10 |

10 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

|

Generator Weight (kg) |

320 |

350 |

350 |

380 |

380 |

380 |

380 |

380 |

380 |

380 |

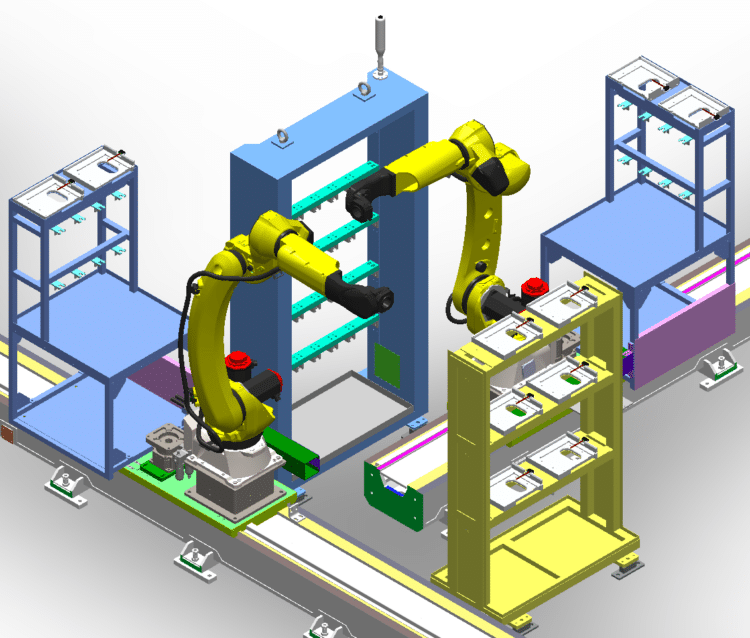

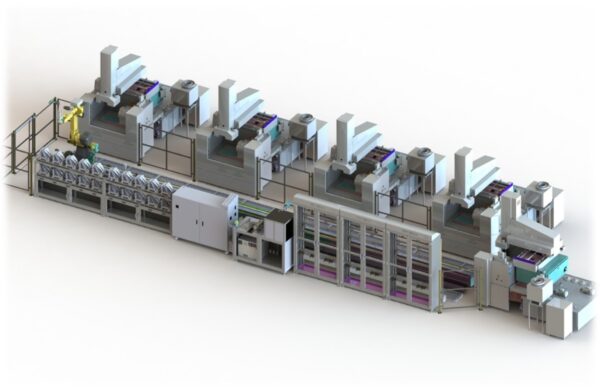

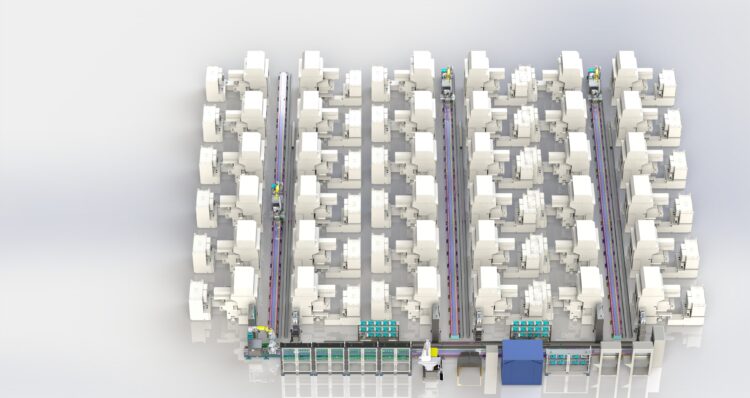

Production Line Automation & Integration using Accutex’s Manufacturing Execution System (MES)

Accutex’s Manufacturing Execution System, or MES is the latest in advanced smart technology and AI. MES not only monitors every aspect of the production process including recording and displaying real-time data on just about anything you can think of, but can also manage things such as multi electrodes, workpieces and machines. Data produced during machine monitoring includes utilization rates, status, and machining processes including milling. MES can also manage customized tools and design projects, measurements and counts necessary in mass-production processes and warehouse management.

MES incorporates Radio Frequency Identification (RFID) technology to record and track real-time data for managing tools and program details. For instance, tools tagged with RFID can be inserted in random positions. Using a robot, RFID tags can be scanned and sorted according to scheduled operations and priorities within the program increasing efficiencies and removing potential errors.

Below are simulation pictures of recently installed production lines using Accutex die sinkers and MES:

AccuteX DS-X Die Sinker Series System Features: