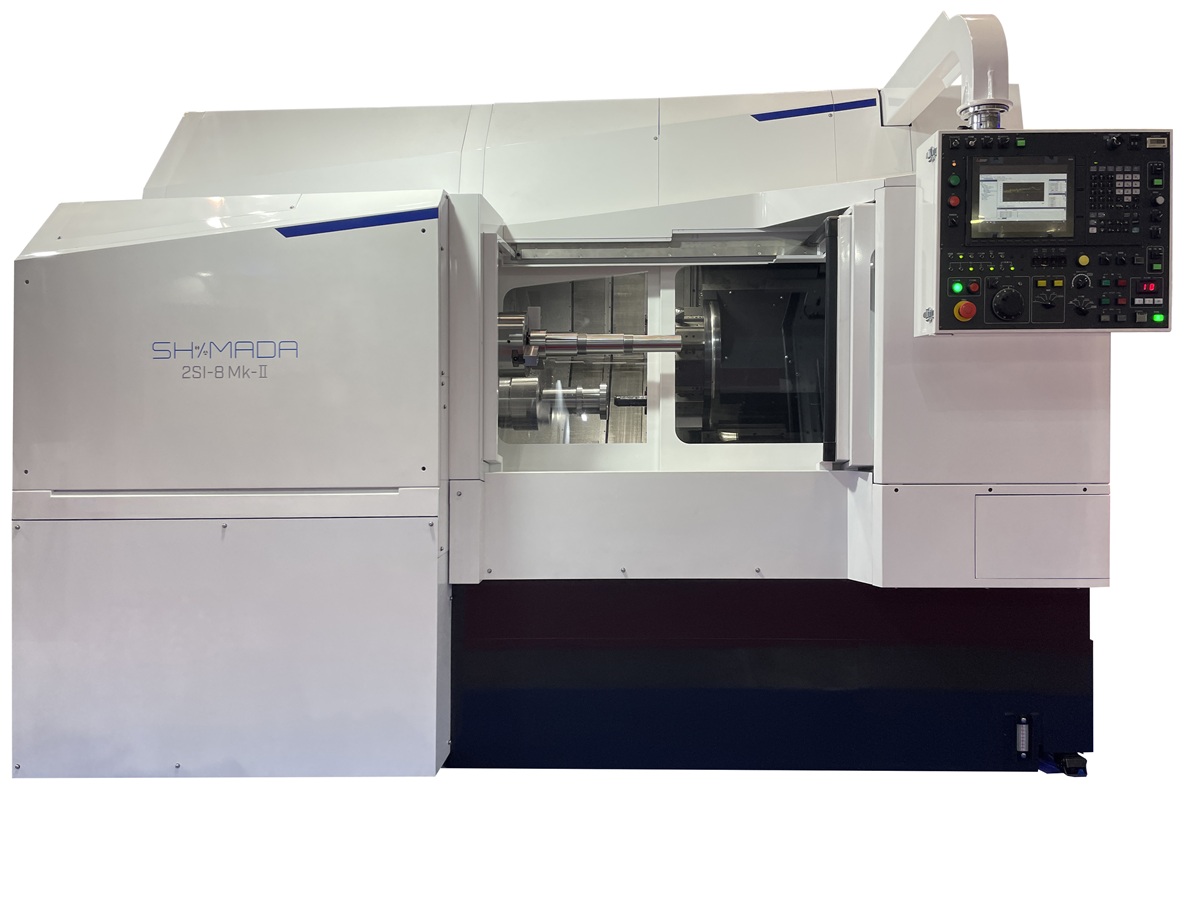

Shimada Kitako 2SI MKII Series – Twin Spindle Single Turret Lathes

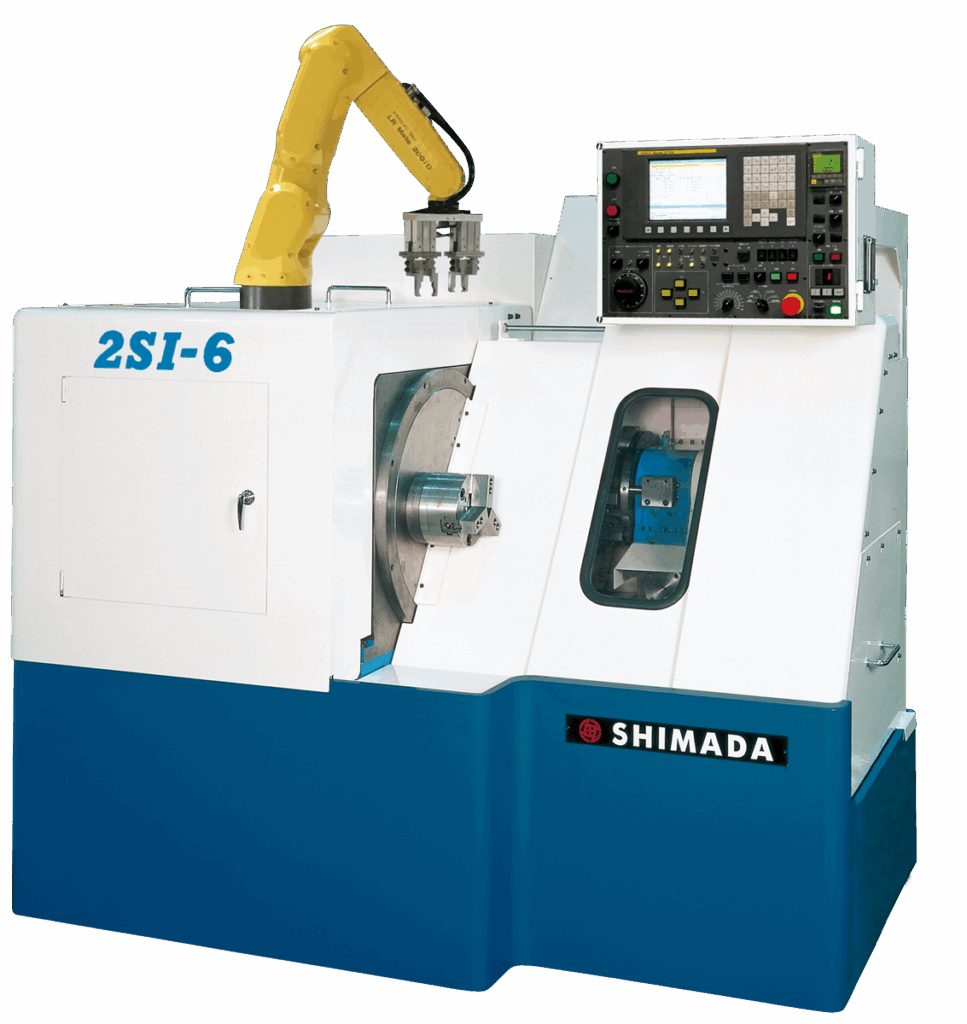

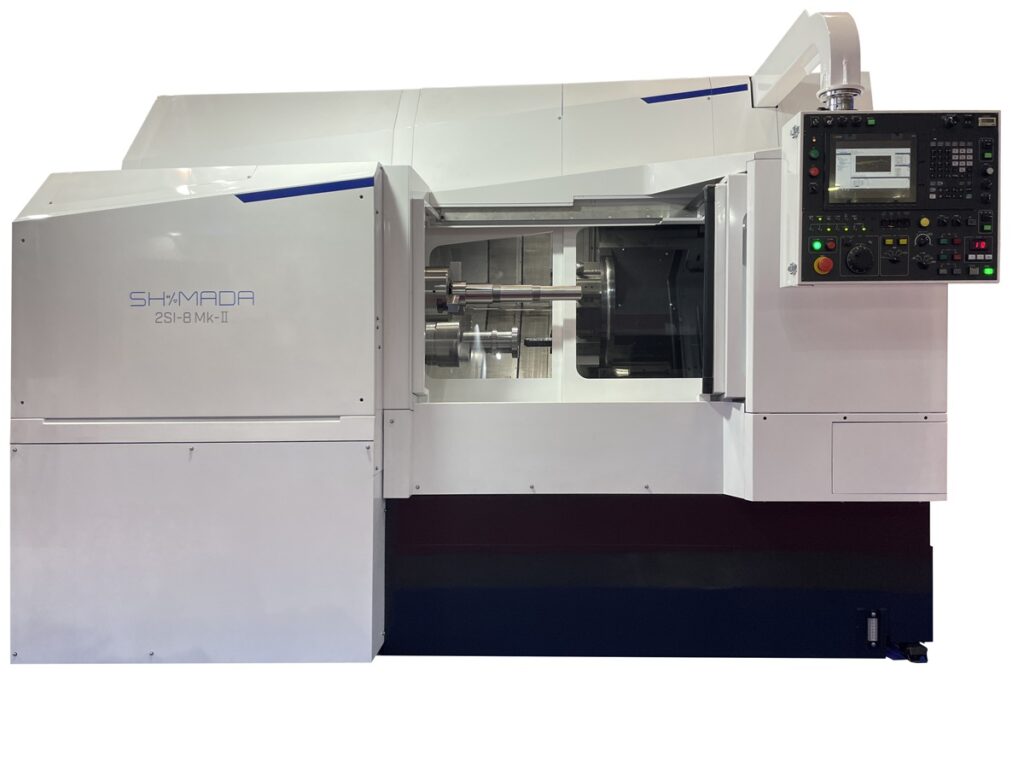

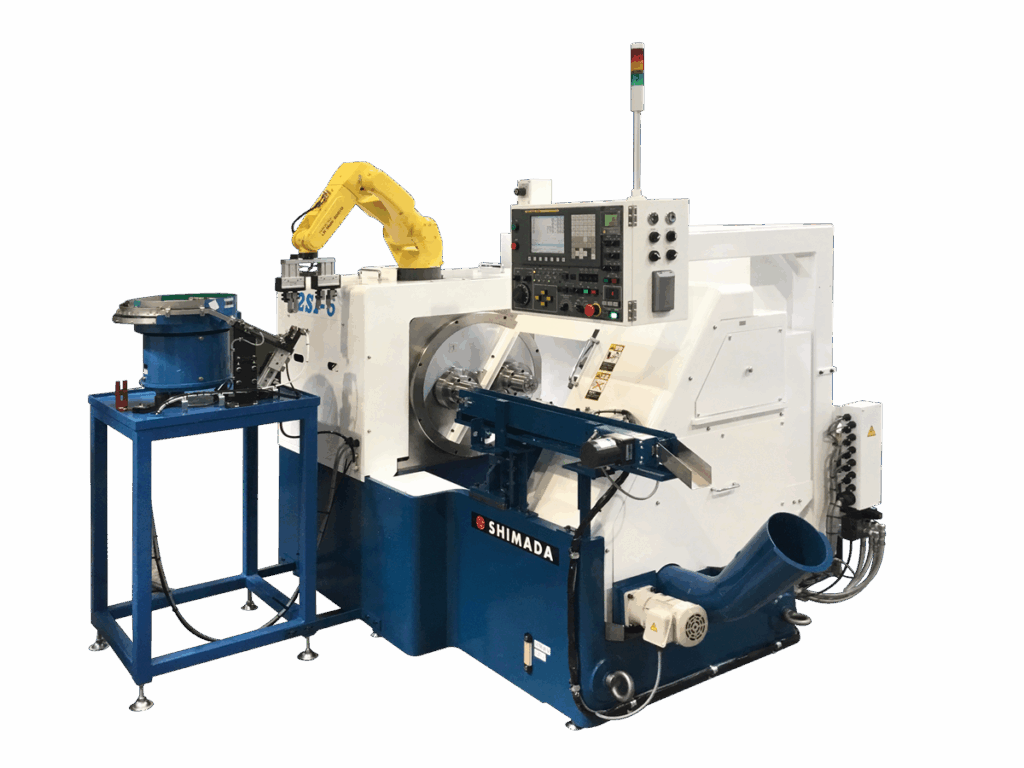

The Shimada–Kitako 2SI MK-II Series consists of twin-spindle, single-turret CNC lathes that allow concurrent machining on both ends of a workpiece. This configuration virtually eliminates spindle idle time by enabling front-side (OP10) and back-side (OP20) operations to run simultaneously. Loading time is reduced to zero, as one spindle performs machining while the other handles loading/unloading—significantly boosting overall productivity and efficiency. Once both operations are complete, the turret drum indexes 180°, and the previously idle spindle begins machining.

The 2SI Series can be configured with 6″, 8″, or 10″ chucks on both spindles. Uniquely, the 2SI-8 MK-II machine is designed with an 8″ chuck but can be adapted to handle a 10″ chuck if the application justifies and clearance and space is evaluated. This flexibility also allows for an asymmetric setup—featuring an 8″ chuck on one spindle and a 10″ chuck on the other—offering added flexibility for different part sizes. Complex, multi-axis, and multi-tasking operations are made possible with the integration of a Y-axis, tailstock, and driven tools (live tooling), effectively transforming the lathe into a compact mill-turn center.

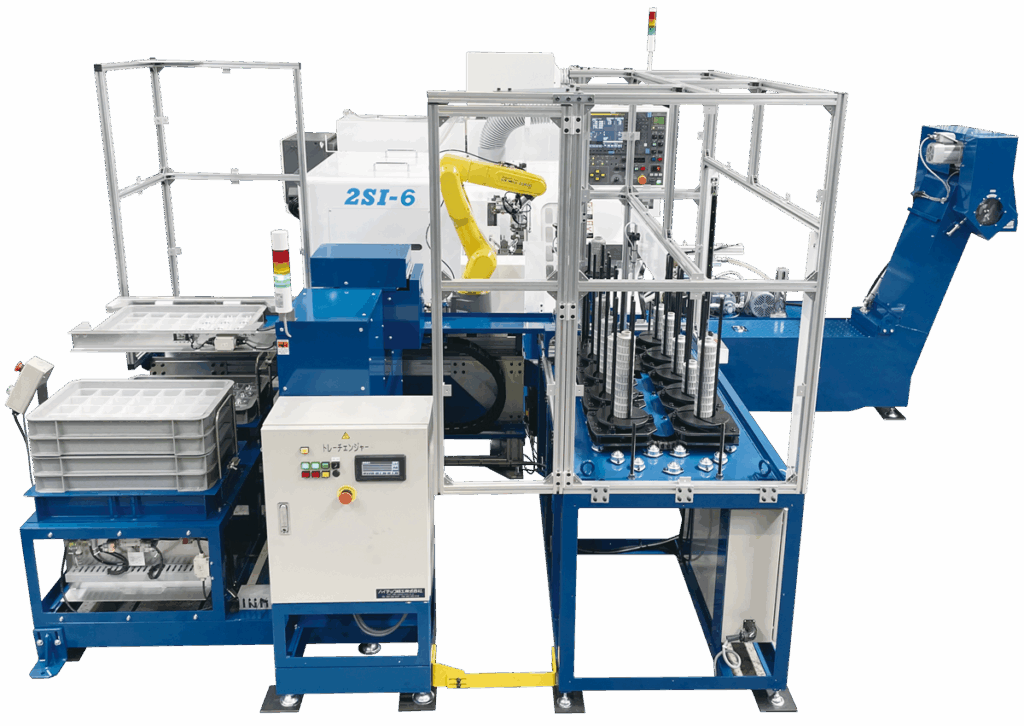

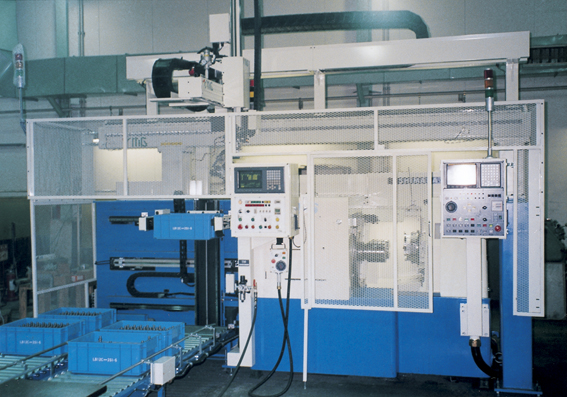

To support affordability and ease of use, the 2SI Series is designed with externally mounted chucks, located outside the machine’s partition door. This design allows for quick manual setups and also facilitates automation. The machine footprint accommodates direct integration of robotic arms without requiring additional floor space. The 2SI Series can also be equipped with a wide range of automation options, including: pusher devices, part length detectors, feeders, chip conveyors, rotary tables, stockers, hopper/lifters, pallet changers, external measurement systems, part reversers, vision inspection, and coolant/air blow-off kits.

Specifications

| Item / Model |

2SI-6

Request a Quote |

2SI-8

Request a Quote |

2SI-8 MK-II

Request a Quote |

2SI-8 MK-II MY

Request a Quote |

|---|---|---|---|---|

|

Swing Over Bed |

∅10.55″ (268 mm) |

∅10.55″ (268 mm) | ||

|

Max Machining Diameter |

∅7.09″ (180 mm) |

∅8.27″ (210 mm) |

∅9.65″ (245 mm) (10.55″ (268 mm) Conditionally) |

∅9.65″ (245 mm) (10.55″ (268 mm) Conditionally) |

|

Max Machining Length |

4.72″ (120 mm) |

4.72″ (120 mm) |

∅9.84″ (250 mm) |

∅9.84″ (250 mm) |

|

No. of Spindles |

2 |

2 |

2 |

2 |

|

Chuck Capacity |

6″ (152.4 mm) |

8″ (203.2 mm) |

8″ (203 mm) (10″ (254 mm) Conditionally) |

8″ (203 mm) (10″ (254 mm) Conditionally) |

|

Spindle RPM |

5,000 RPM |

3,500 RPM |

60 – 6,000 RPM |

60 – 6,000 RPM |

|

Motor |

(2) 5.5 / 7.5 kw |

(2) 5.5 / 7.5 kw |

(2) 15/18 kw Output |

4.0 kw Output 50.0 N • m Torque Rotary Tool Spindle Motor |

|

No of Tools / Turret Type |

8 Station (12 opt.) Gang Tool or Turret |

8 Station (12 opt.) Gang Tool or Turret |

10 Station Turret (12 opt.) |

10 Station Turret for Rotary Tools (12 opt.) |

|

O.D. Bite Shank Size |

∅0.984″ (25 mm) |

∅0.984″ (25 mm) | ||

|

I.D. Bite Shank Size |

∅1.57″ (40 mm) |

∅1.57″ (40 mm) | ||

|

Rotary Tool Spindle Speed |

6,000 RPM max. | |||

|

X-Axis Travel |

4.72″ (120 mm) |

4.72″ (120 mm) |

7.28″ (185 mm) |

7.28″ (185 mm) |

|

Z-Axis Travel |

6.69″ (170 mm) |

6.69″ (170 mm) |

9.84″ (250 mm) |

9.84″ (250 mm) |

|

Y-Axis Travel |

+/- 25 mm | |||

|

Rapid Feed Rate |

15 M/min. |

15 M/min. |

X: 30M/min. Z: 30M/min. |

Y: 21 M/min. |

|

Tailstock |

MT #4 Servo Drive |

MT #4 Servo Drive | ||

|

Tailstock Travel |

19.69″ (500 mm) |

19.69″ (500 mm) | ||

|

Spindle Centerline Height |

37.80″ (960 mm) |

37.80″ (960 mm) |

Machining Axis: 42.83″ (1088 mm) Detachable Axis: 50.11″ (1273 mm) |

Machining Axis: 42.83″ (1088 mm) Detachable Axis: 50.11″ (1273 mm) |

|

Machine Dimensions (LxWxH) |

74.80″ x 62.99″ x 70.87″ (1900 x 1600 x 1800 mm) |

74.80″ x 62.99″ x 70.87″ (1900 x 1600 x 1800 mm) |

98.43″ x 68.90″ x 70.87″ (2500 x 1750 x 1800 mm) |

98.43″ x 68.90″ x 70.87″ (2500 x 1750 x 1800 mm) |

|

Machine Weight |

7,937 lbs. (3600 kg) |

8,378 lbs. (3800 kg) |

14,330 lbs. (6500 kg) |

15,212 lbs. (6900 kg) |

Mk-Ⅱ×600-1024x949.jpg)

Mk-Ⅱ×600.jpg)