Johnford FBMC Series – Floor-Type Horizontal Boring Mills

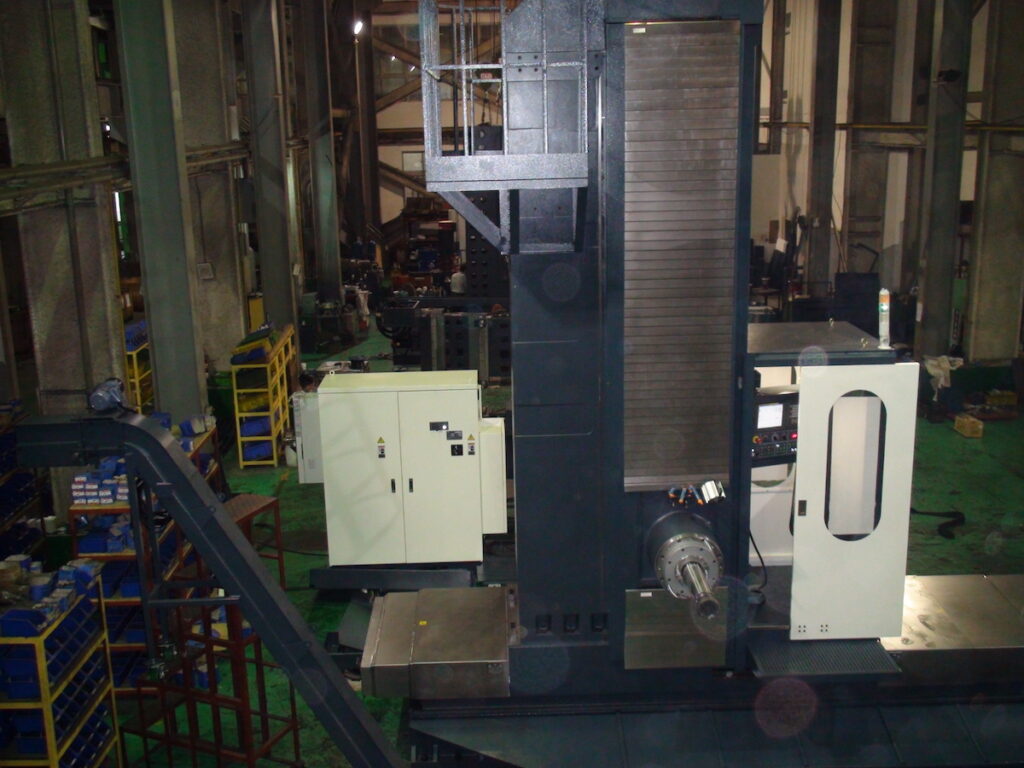

Johnford FBMC-160 floor-type horizontal boring mills are engineered for precision machining of large parts. The massive machines can be custom-configured to exactly meet specific production needs. Standard axis travels for X, Y, Z, W and V axes are 236″ x 137.8″ x 47.24″ x 39.37″ x 78.74″ (6,000 mm x 3,500 mm x 1,200 mm x 1,000 mm x 2,000 mm). Y axis travel can extend to 196.8″ (5,000 mm) and X axis travel can reach to 591″ (15,011 mm) and beyond.

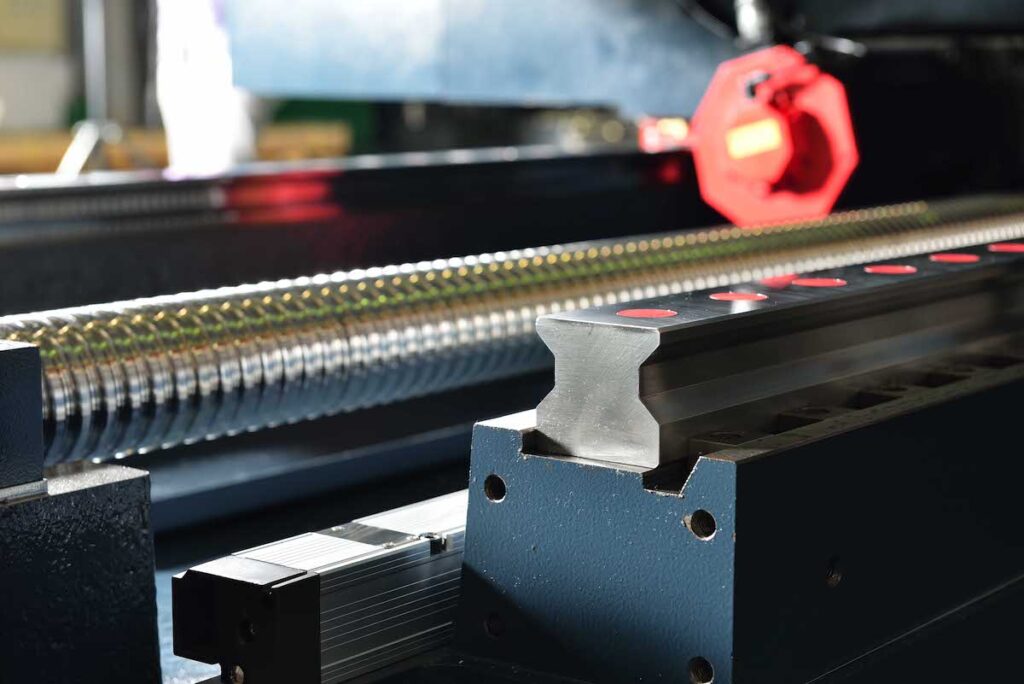

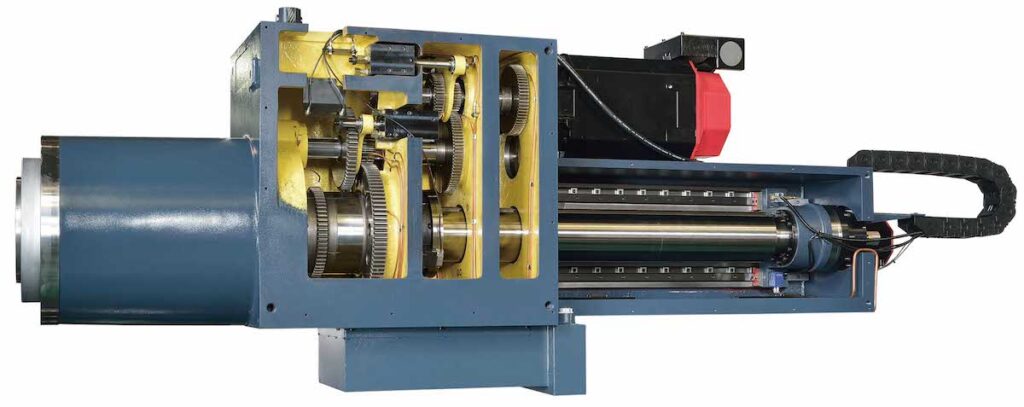

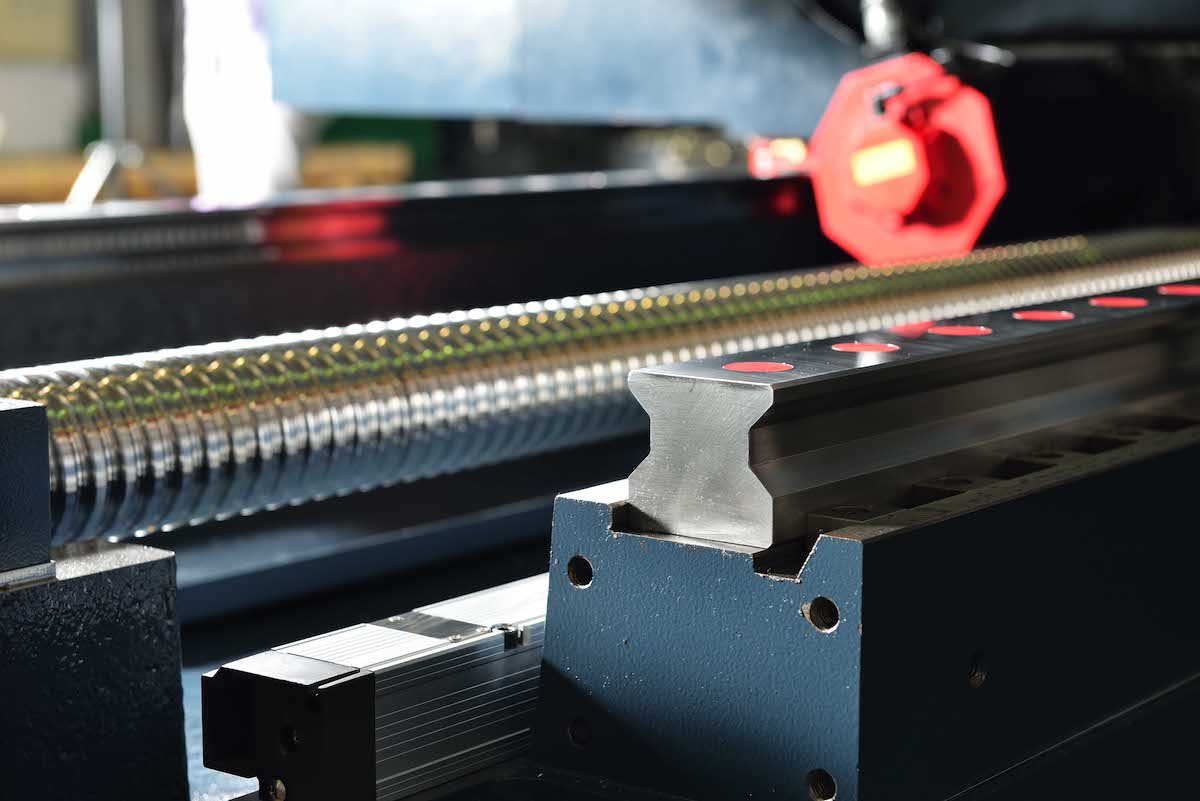

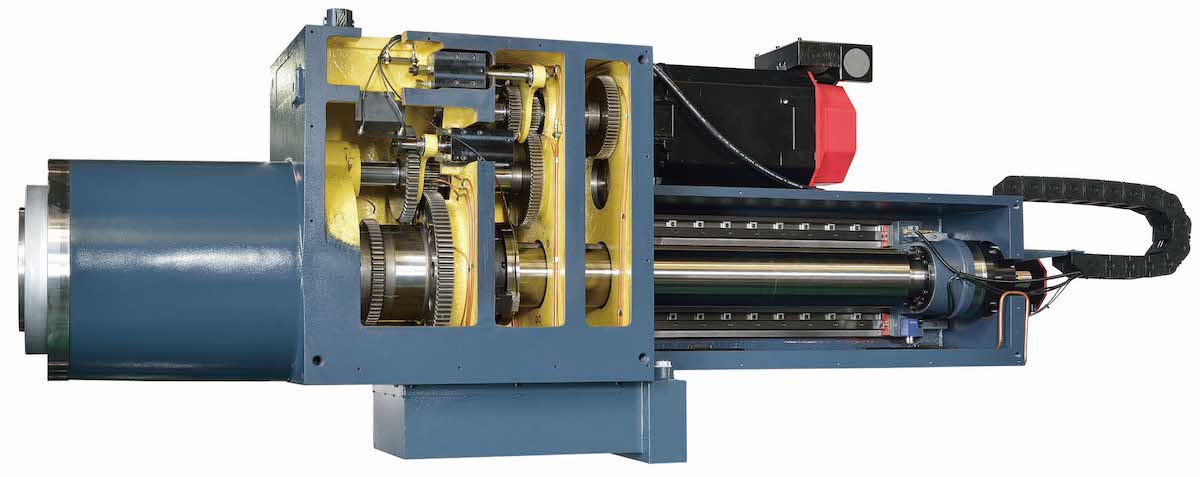

The machines feature a moving column X axis and both a fixed and a rotary table for the V axis, a heavy duty design that results in maximum rigidity and accuracy. The X axis base is a one piece Meehanite cast iron construction. Roller ways in X, Y, Z, and V have precision Schneeberger 65mm bearings. A pressurized automatic oil system force lubricates the ways. A dual rack and pinion drive moves the X axis and provides high speed rapid traverse of 630″/min (16 m/min) with near zero backlash. Large diameter pre-tensioned ballscrews and servo motors position the other axes. The Y and V axes feature 3.15″ (80 mm)-dia. ballscrews while Z and W feature 2.5” (63.5 mm)-dia ballscrews.

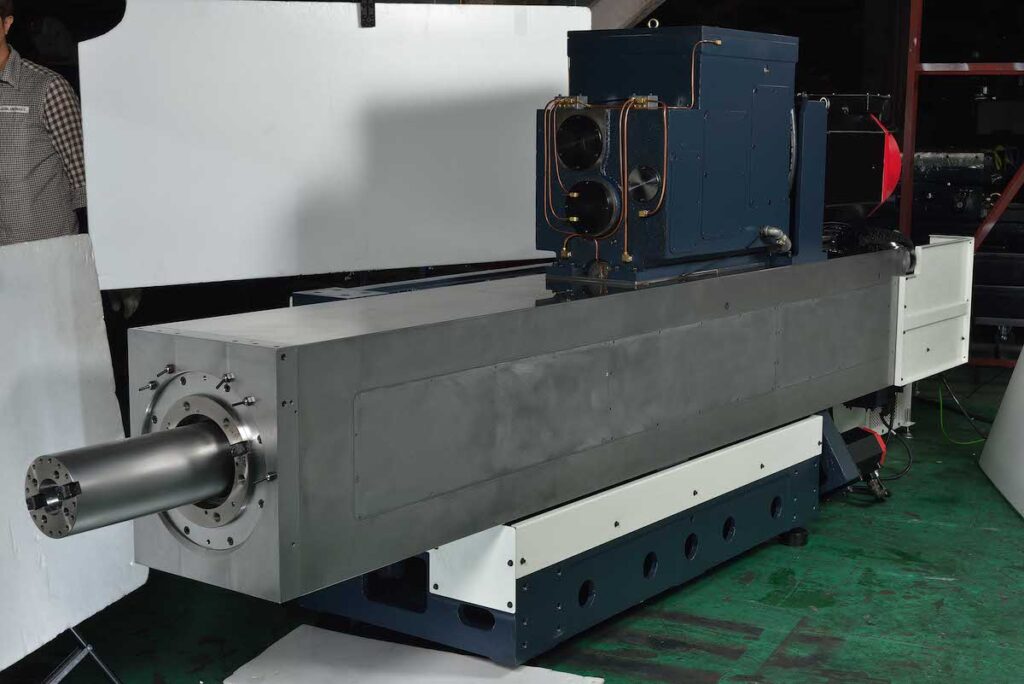

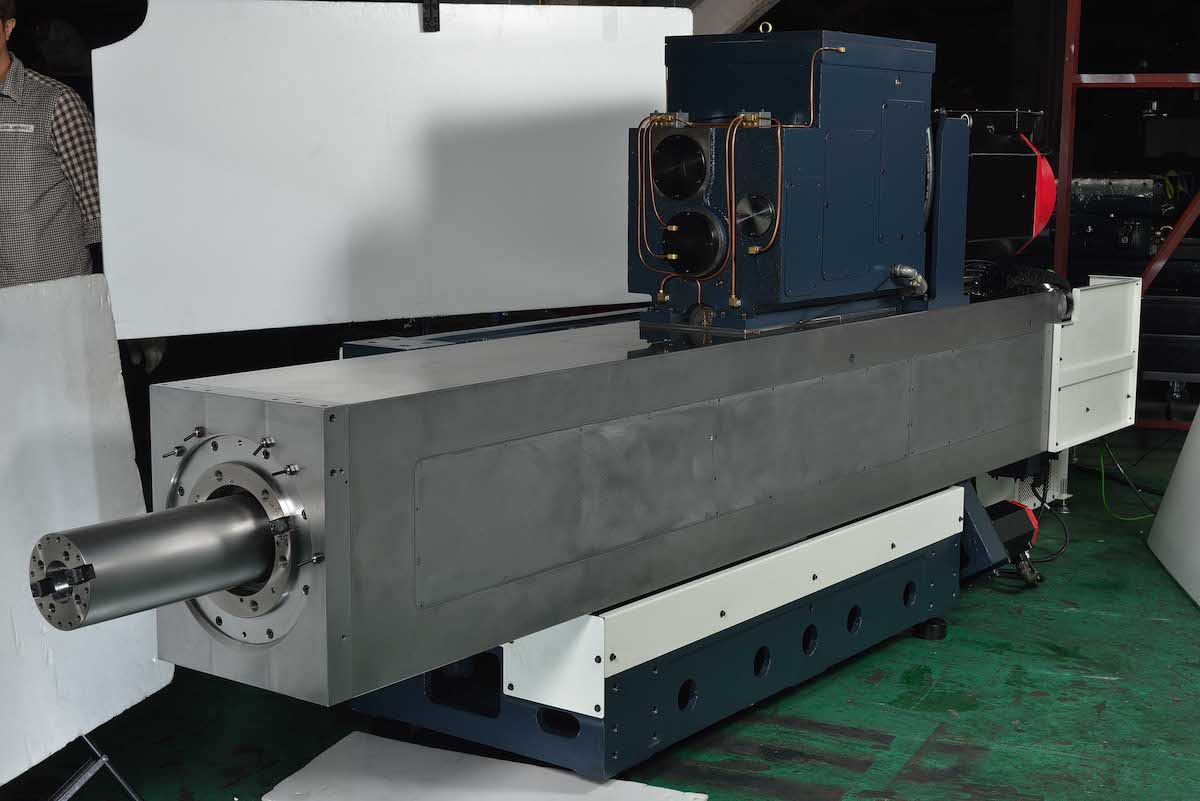

Heidenhain scales are standard in all linear axes. The headstock features a 20.5″ (520 mm) x 17.7″ (450 mm) rectangular ram for the Z axis and a 6.3″ (160mm) bar for the W axis.

The 100 hp, 2,200 rpm main spindle motor has a 3 speed gear drive, and the spindle and headstock are oil cooled to minimize thermal growth.

Standard features include a stand-alone heavy-duty 60 tool arm type automatic tool changer, a comprehensive chip removal system, a high volume coolant system, a full B-axis rotary table with built-in rotary scale, and 300 psi coolant through the spindle.

The standard Fanuc 31iM-B control is suited for all types of general machining applications and provides options for high speed, high accuracy mold and die machining.

Specifications

| Item / Model |

FBMC-160

Request a Quote |

|---|---|

|

X Travel (in.) |

236 – (up to 591 and beyond) |

|

Y Travel (in.) |

137.80 – 196.85 |

|

Z Travel (in.) |

47.24 |

|

W Travel (in.) |

39.37 |

|

V Travel (in.) |

78.74 |

|

Ram Cross Section (in.) |

17.72 x 20.47 |

|

Spindle Bar (in.) |

6.3 |

|

Table Size Length (in.) |

275.59 – 393.70 |

|

Table Size Width (in.) |

98.43 |

|

Table Loading Capacity (lbs/sq. ft.) |

1024 |

|

Max. Workpiece Load Flat Table (lbs.) |

2,200 lbs./sq.ft |

|

Spindle (hp.) |

100 |

|

Spindle Speed (RPM) |

10 – 2,200 |

|

Spindle Nose Taper |

CAT-50 |

|

Spindle Drive Motor (HP) |

80/100 |

|

Spindle Drive Motor (S1/S6 – 60%) (kW) |

60 /75 |

|

Spindle Drive |

3 Speed Gearbox |

|

X/Y/Z/W/V Axis Rapid Traverse (in./min.) |

X=630.4 / Y,Z,V=472.8 / W=236.4 |

|

X/Y/Z/W/V Axis Cutting Feed Rate (in./min.) |

1 – 236.22 |

|

X/Y/Z/W/V Axis Servo Motor (HP) |

X=12 / Y=8 / Z,W,V=9 |

|

ATC Capacity |

60 (80/120 opt.) |

|

ATC Max Tool Diameter (in.) |

∅9.84 |

|

ATC Max Tool Length (in.) |

15.75 |

|

ATC Max Tool Mass (lbs.) |

55 |

|

ATC Max Tool Diameter of Full Setting (in.) |

∅4.92 |

|

ATC Tool Selection |

Bi-Direction Random Type, Shortest Path |

|

Pneumatic Pressure |

85 PSI |

|

Rotary Table Size (in.) |

98.43 x 118.11 |

|

Rotary Table Capacity (lbs.) |

55,000 (100,000 opt.) |

|

Machine Length (in.) |

799.21 – 917.32 |

|

Machine Width (in.) |

564.96 |

|

Machine Height (in.) |

230.31 – 289.37 |

|

CNC Control Type |

FANUC 31iMB |

|

Weight (lbs.) |

240,000 – 349,800 (est. weights increase |

Optional Control Features – Fanuc 31iM-B