Nexturn SA(XIII) 3 Channel & 3 Y-Axes Swiss Lathe Series

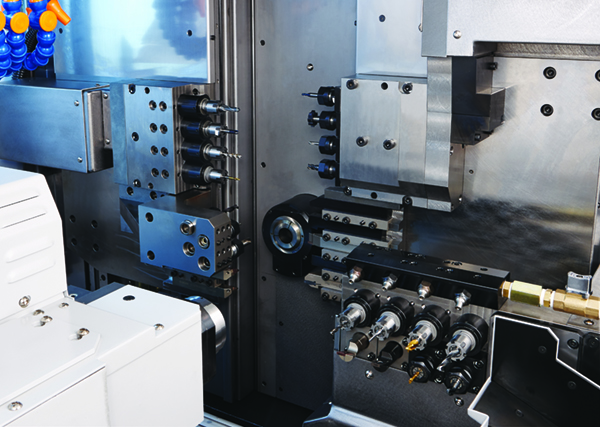

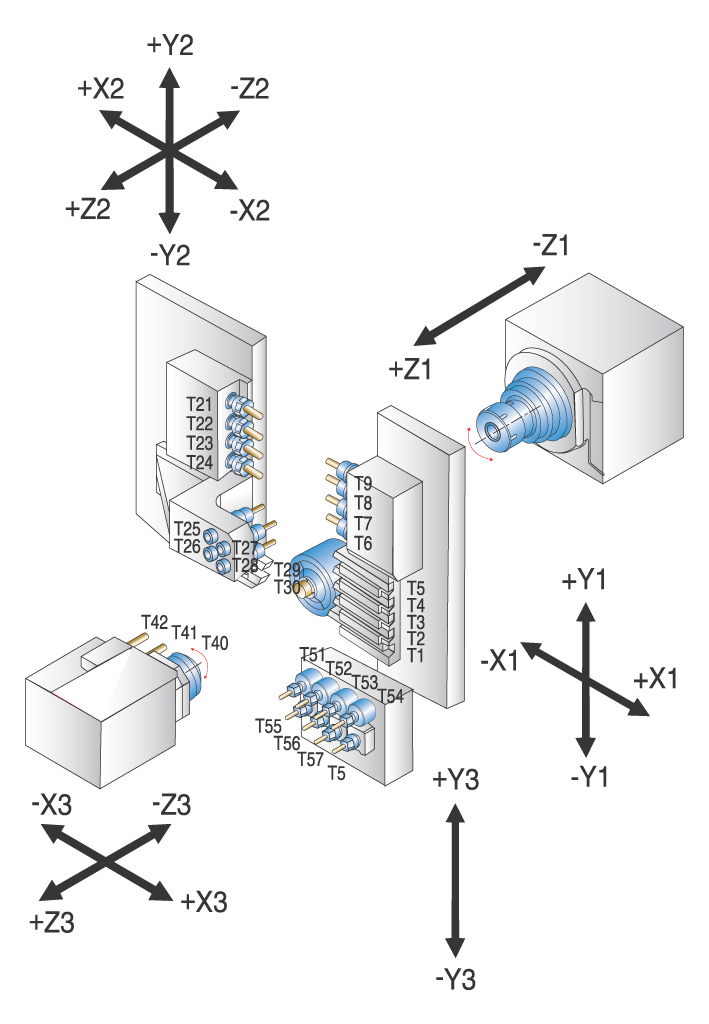

The SA XIII series of Nexturn Swiss CNC lathes consists of three models with or without rotary synchronous guide bushings. The XIII series is equipped with an opposing gang tooling system holding a maximum of 14 live tools for high productivity when machining complex parts. Use of guide bushings permits turning of longer parts, while machines without guide bushings are ideal for processing short parts and cold drawn material.

The machines feature up to 11 axes and up to 29 total tools. Maximum bar diameter capacity of the main and sub spindles is 32mm – 45mm, depending on machine size. Maximum turning lengths are 120mm – 279mm.

Main spindles and sub spindles provide as much as 20 HP (15kW) at speeds as high as 8,000 RPM while offering full C-axis capability. The synchronous sub-spindle permits simultaneous front and backworking. Live tools provide 1.3 HP (1 kW) and 6,000 RPM. Rigid tapping is standard.

Excellent rigidity results from the use of FEA technology in machine structure design. The slant-bed Nexturn machines maximize ease of use with ergonomically arranged controls and fully opening covers and doors.

Specifications

| Item / Model |

SA-32XIII

Request a Quote |

SA-38XIII

Request a Quote |

SA-45XIII

Request a Quote |

|---|---|---|---|

|

FREE TRACER 32V Bar Feeder |

FREE TRACER 51V Bar Feeder |

FREE TRACER 32V Bar Feeder Package | |

|

Number of Axes |

11 |

11 |

11 |

|

Number of Channels |

3 |

3 |

3 |

|

Bar Capacity (Front/Rear) |

32 mm / 32 mm |

38 mm / 38 mm |

45 mm / 45 mm |

|

Guide Bushing Type |

Synchronous |

Synchronous |

Synchronous |

|

Main Spindle |

10 HP / 8,000 RPM |

10 HP / 8,000 RPM |

20 HP / 6,000 RPM |

|

Sub Spindle |

3 HP / 8,000 RPM |

3 HP / 8,000 RPM |

7.5 HP / 6,000 RPM |

|

Max. Turn Length |

11″ |

11″ |

4.72″ |

|

Total Tools |

29 |

29 |

24 |

|

Fixed Tools (Front/Rear) |

13 / 4 |

13 / 4 |

13 / 4 |

|

Live Tools (Front/Rear) |

8 / 4 |

8 / 4 |

7 / 4 |

|

Live Tools |

6,000 RPM |

6,000 RPM |

6,000 RPM |

|

Live Tools |

1.3 HP1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

1.3 HP / 6,000 RPM |

|

C Axis Contouring |

Main/Sub |

Main/Sub |

Main/Sub |

|

CNC Control |

FANUC 31iT |

FANUC 31iT |

FANUC 31iT |

|

Weight |

8,140 lbs. |

8,140 lbs. |

8,800 lbs. |

FAQs

Why do they call it a Swiss?

Pretty much the reason you would think — the Swiss lathe originated in Switzerland! First used to make fine threaded parts and small shafts for the Swiss watch industry, the machines were later used to make intricate gun parts. However, those early nineteenth century watchmakers would hardly recognize the CNC Swiss machines of today. The early machines utilized a disc cam to rotate tooling to a workpiece, which was held in place by a collet and supported by a guide bushing. Disc cams moved the tools in a radial motion while simultaneously altering the headstock position. Swiss machines improved by leaps and bounds in the 1970s, with computer numerical controls (CNC) replacing cams.

When is it worth it to buy a Swiss lathe?

A Swiss lathe is a great option for shops that run high volume parts and need lights-out capabilities. Changeover on a Swiss lathe is minimal, especially when running a family group of similar style parts together. Another benefit is that Swiss machining is able to produce parts to high accuracy specifications, which means reduced costs from returned parts.

Why is the Swiss machine tooling capacity significant?

CNC Swiss machines can accommodate 20 or more tools in the tool zone, many with live tooling. When combined with a sub-spindle and backworking stations, this array of tools can virtually eliminate the need for secondary operations on complex parts, allowing Swiss machines to produce finished, ready-to-ship components.