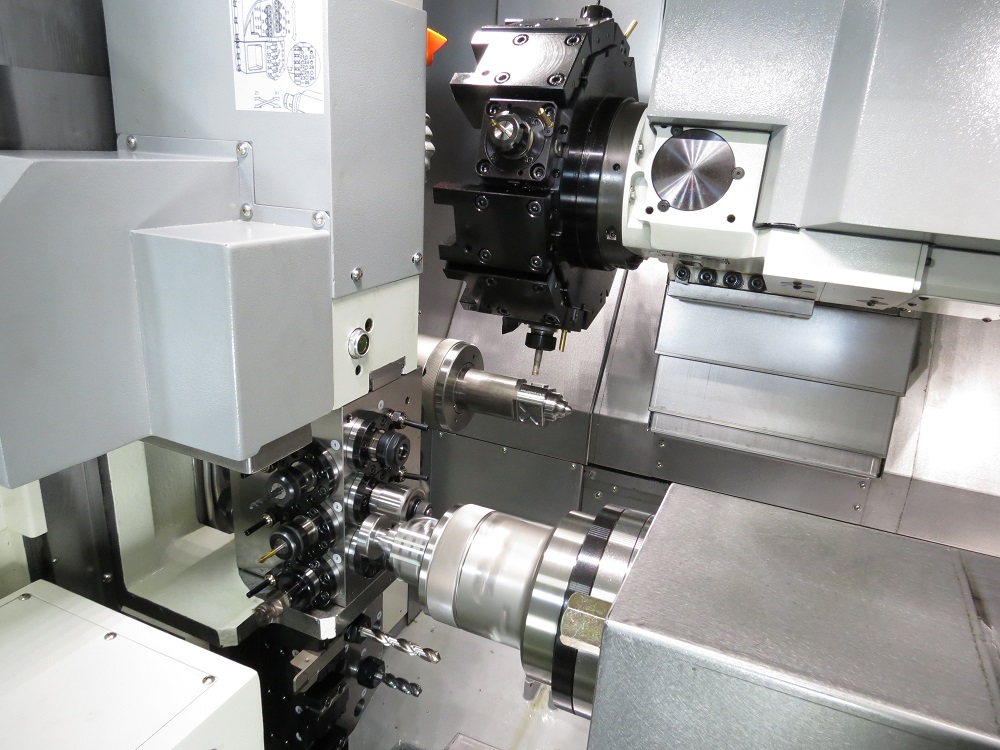

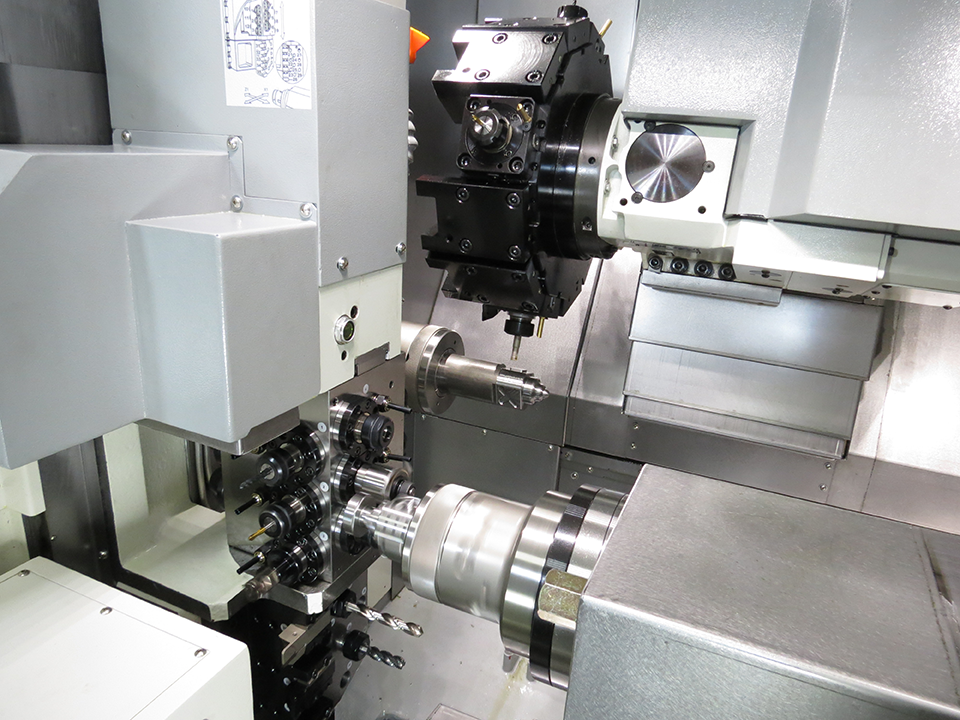

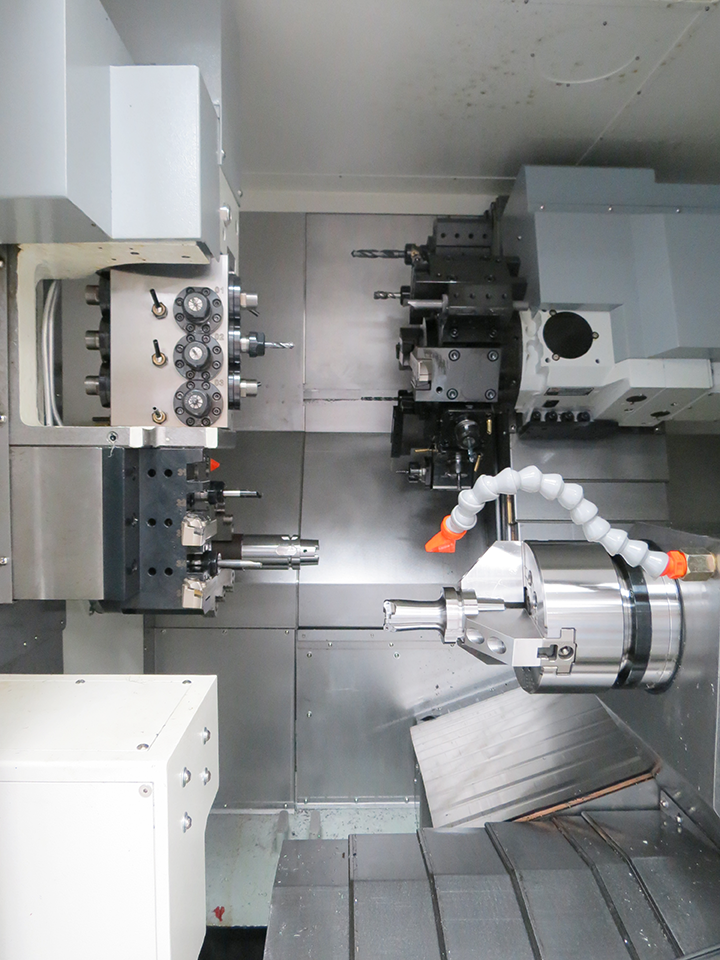

Quicktech T8 Hybrid 9-Axis Mill-Turn Center with Turret & B-Axis

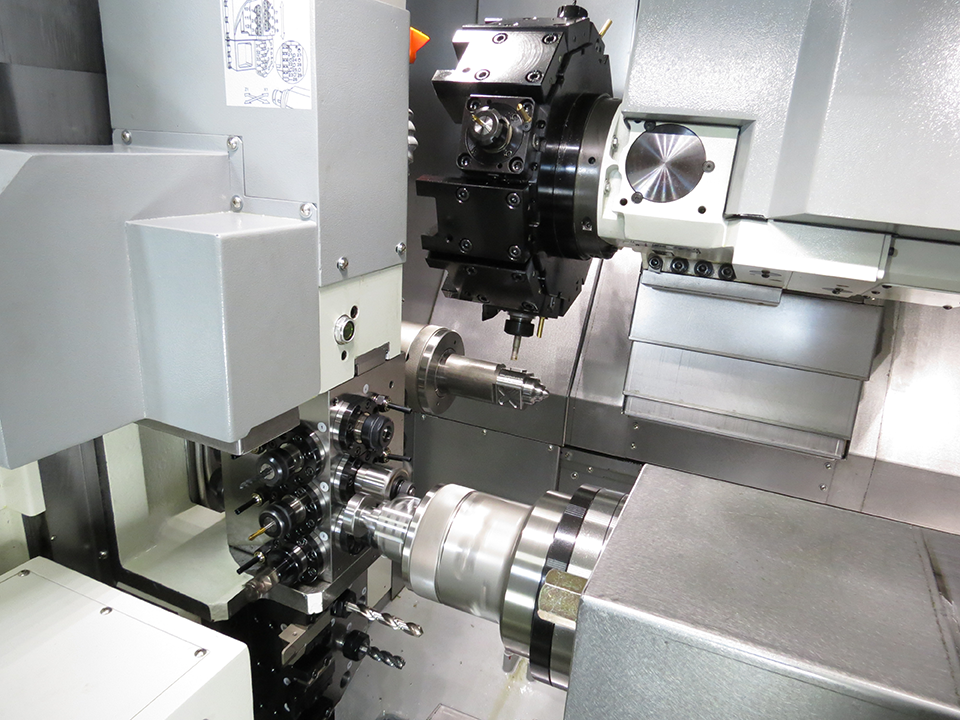

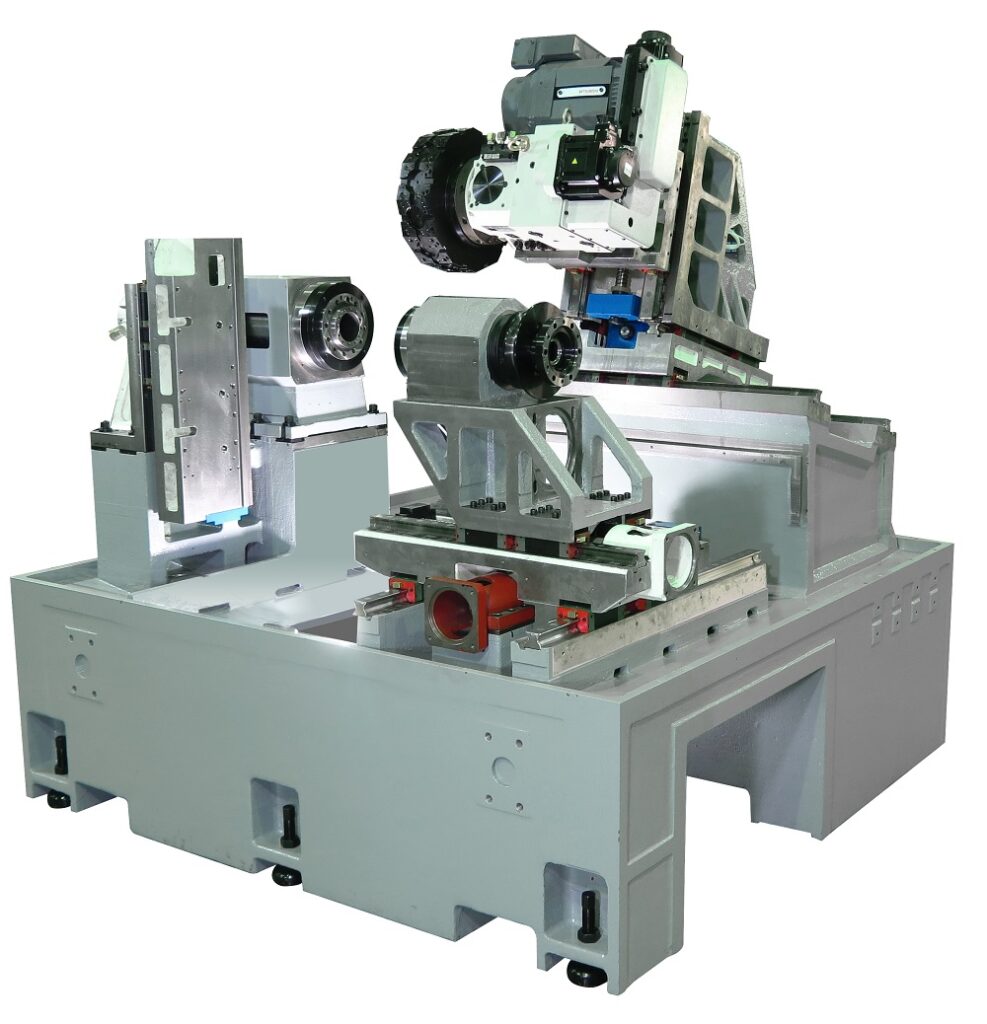

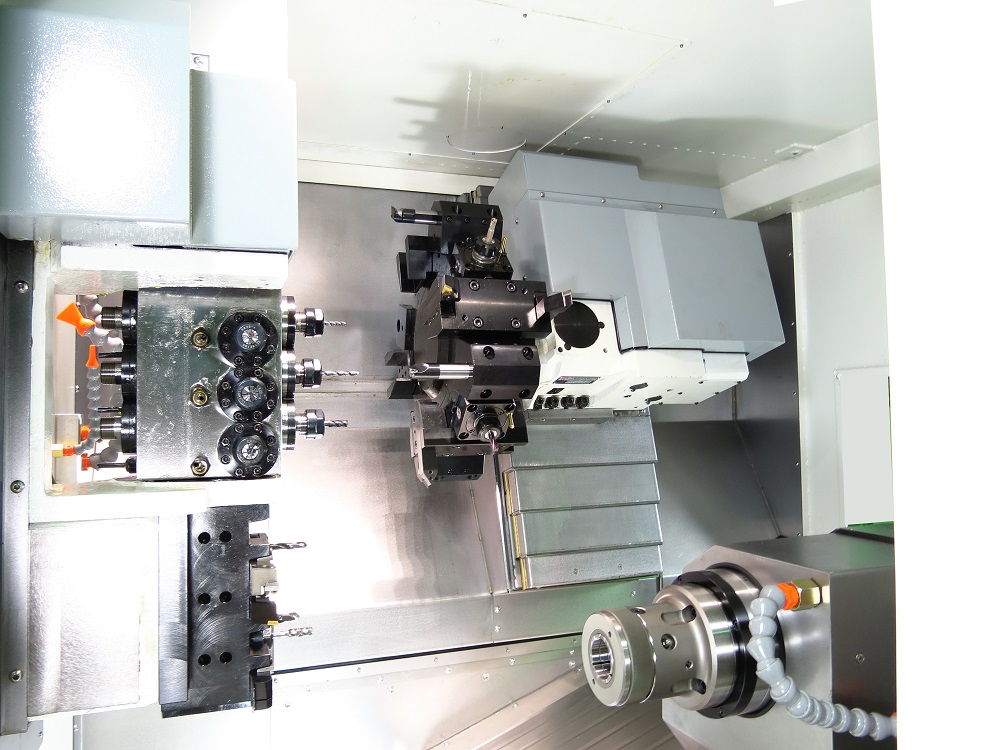

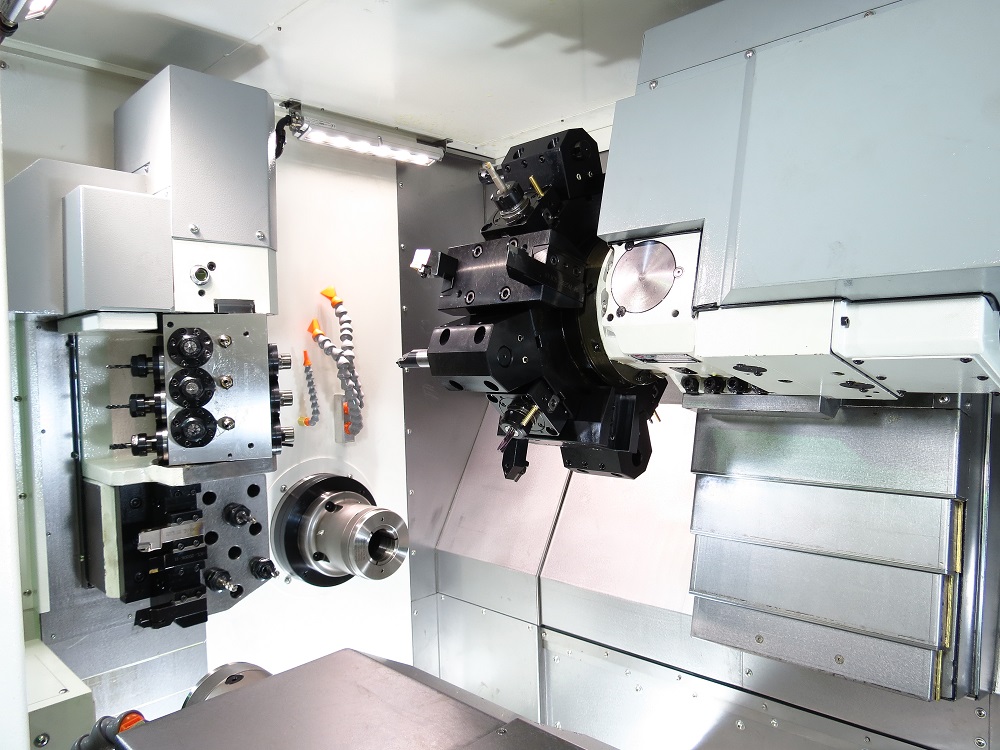

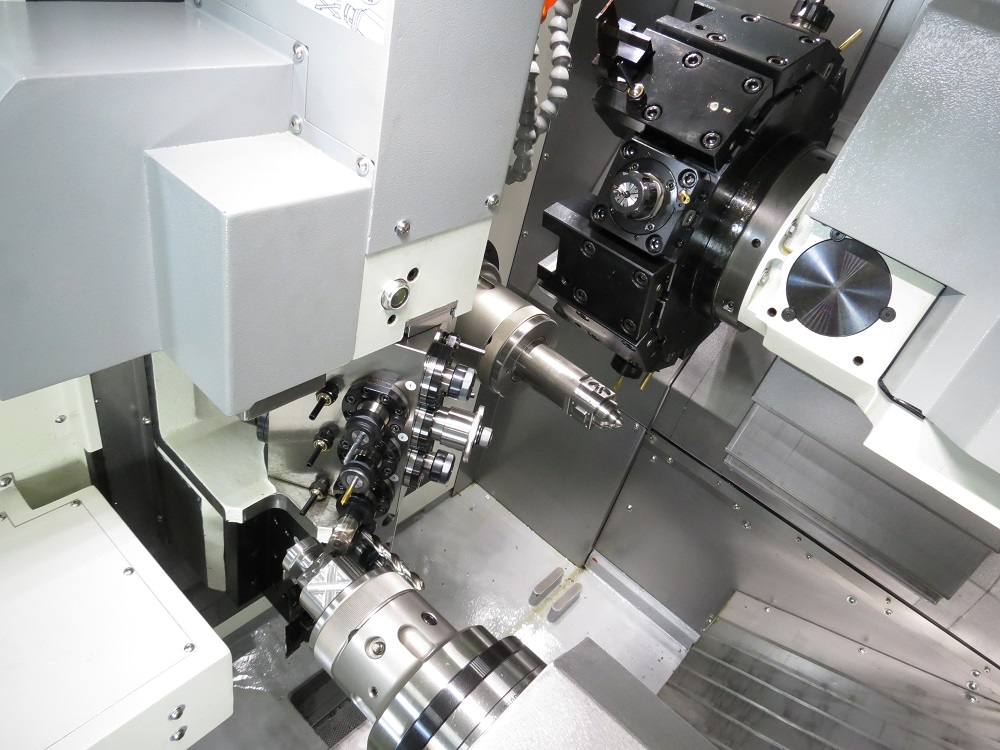

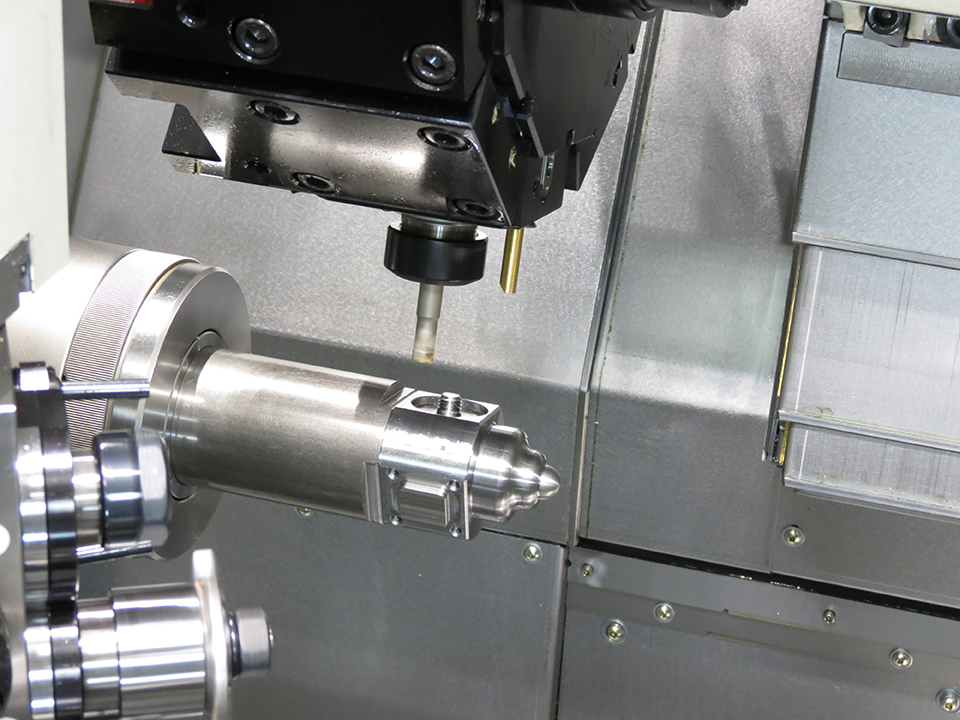

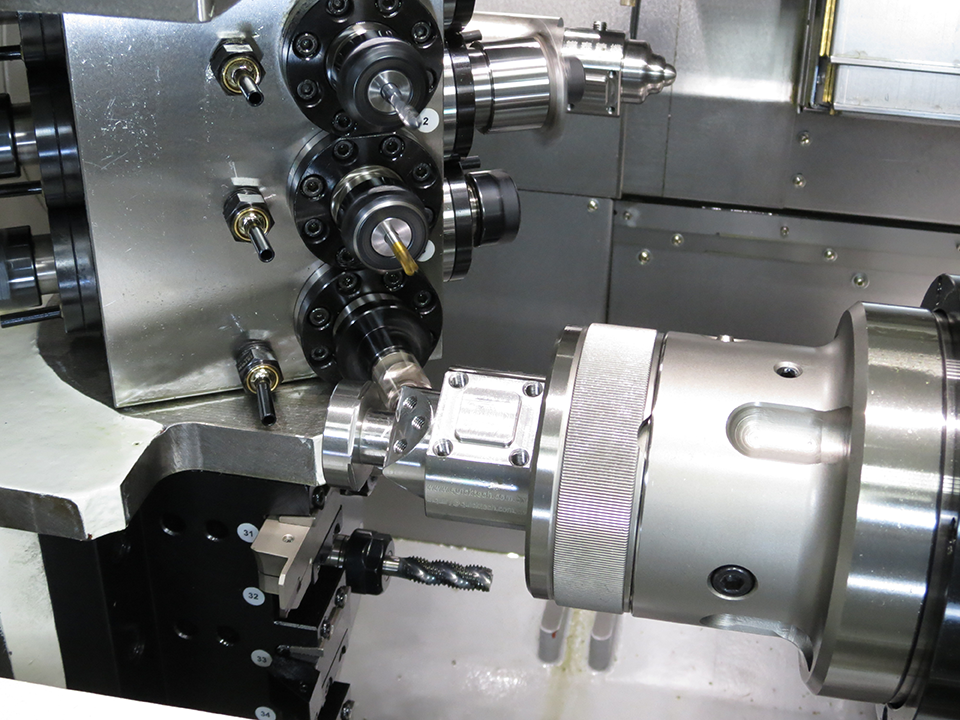

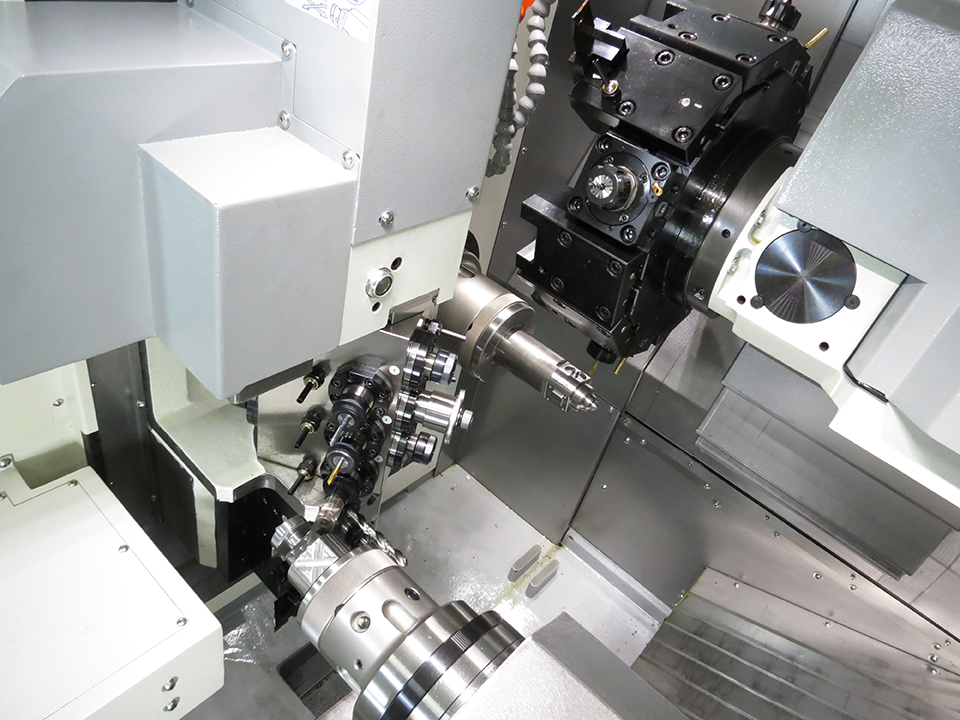

The Quicktech T8 Hybrid combines the versatility of a 9-axis twin-spindle CNC mill-turn center with both a BMT-55 turret and a 4-axis gang slide featuring a 360° B-axis, enabling complete, complex machining in one compact footprint. Designed for high-precision, high-mix production, the T8 Hybrid is ideal for aerospace, medical, defense, and precision automotive manufacturers that require intricate geometries, ultra-fine surface finishes, and full done-in-one capability.

Competitors include Haas, Doosan, DMG Mori, and Mazak, but Quicktech’s hybrid turret-and-B-axis architecture delivers unmatched flexibility and value in its class.

Key Features

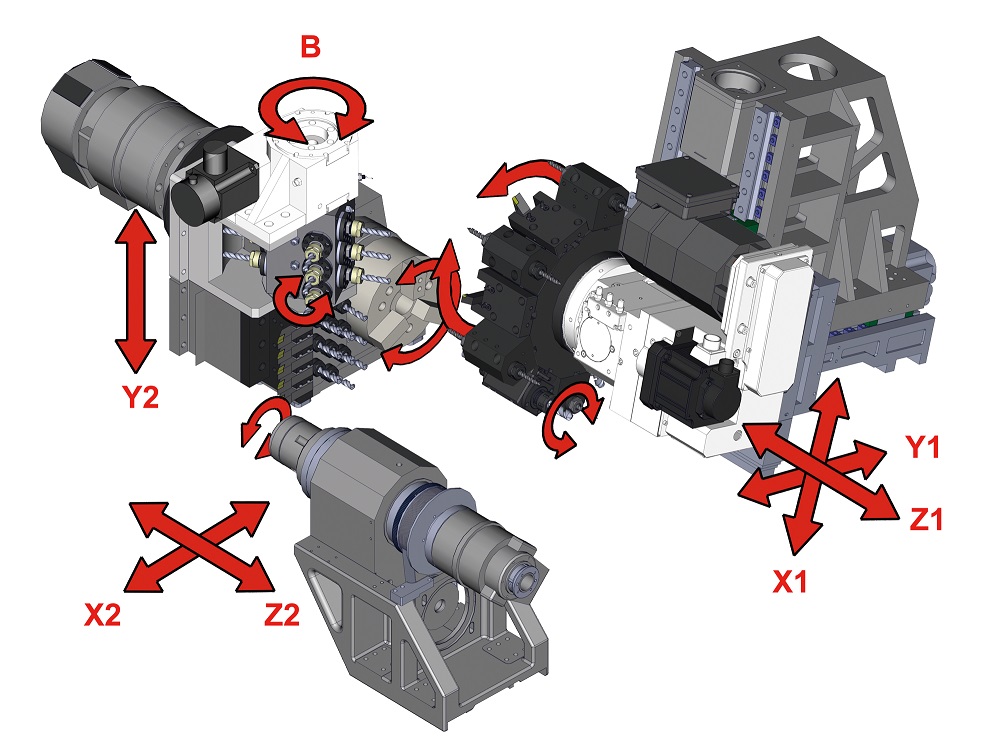

- 9-Axis Machining Platform: Combines dual turning spindles, two live milling spindles, a full 360° B-axis, and a true linear Y-axis for complete simultaneous control.

- Dual Spindle System:

• Main Spindle – 15 HP motor, 8″ chuck (65 mm bar capacity) with C-axis braking system.

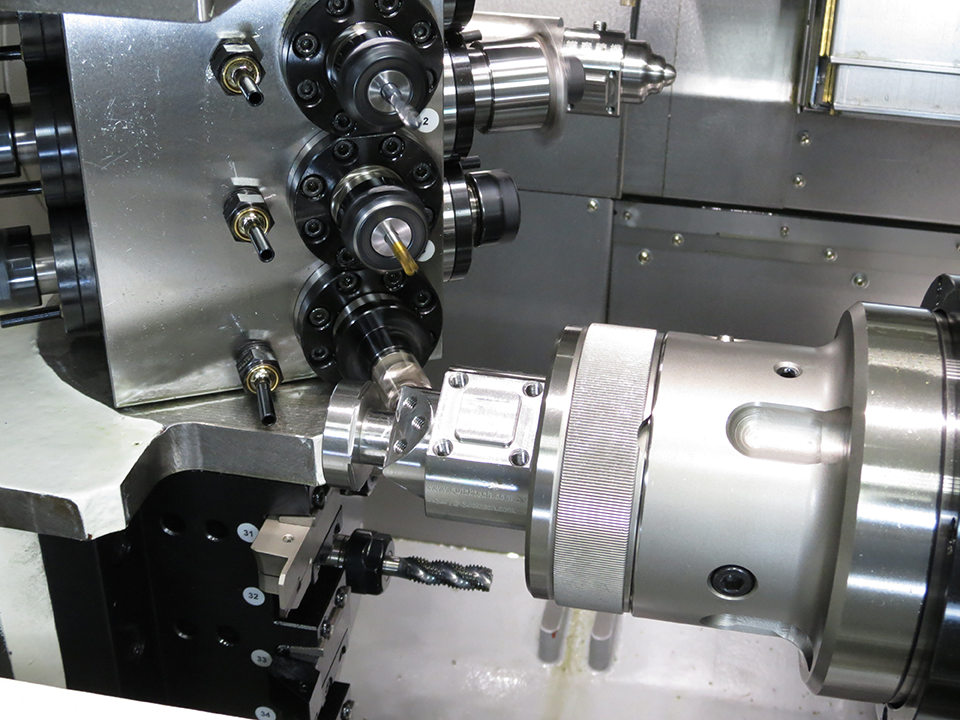

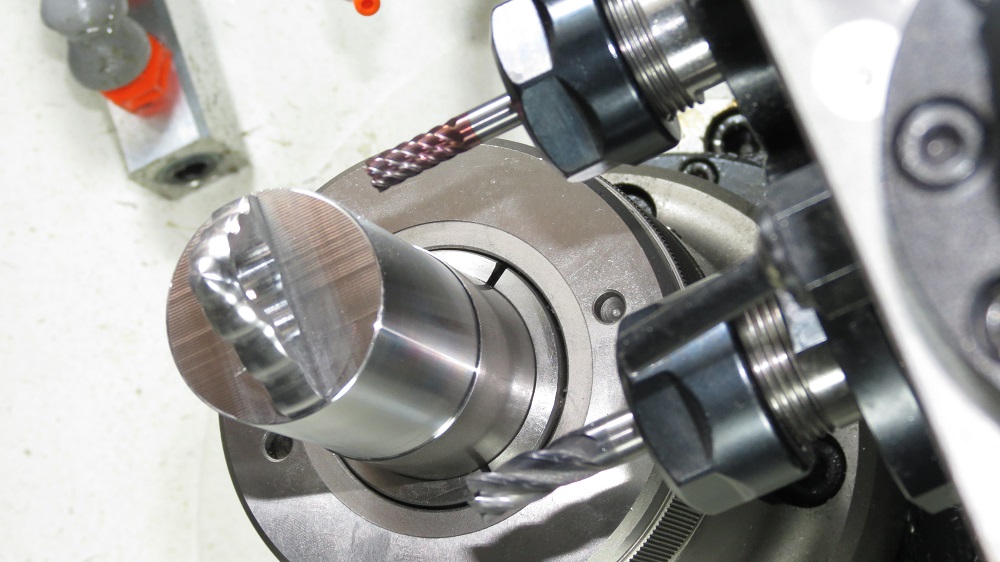

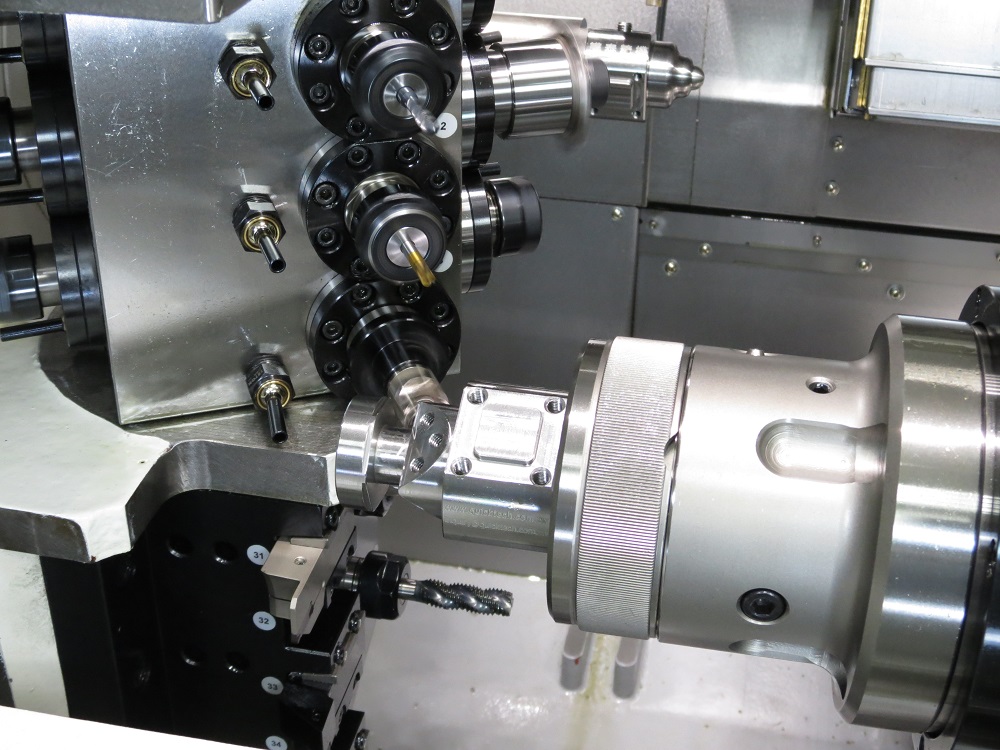

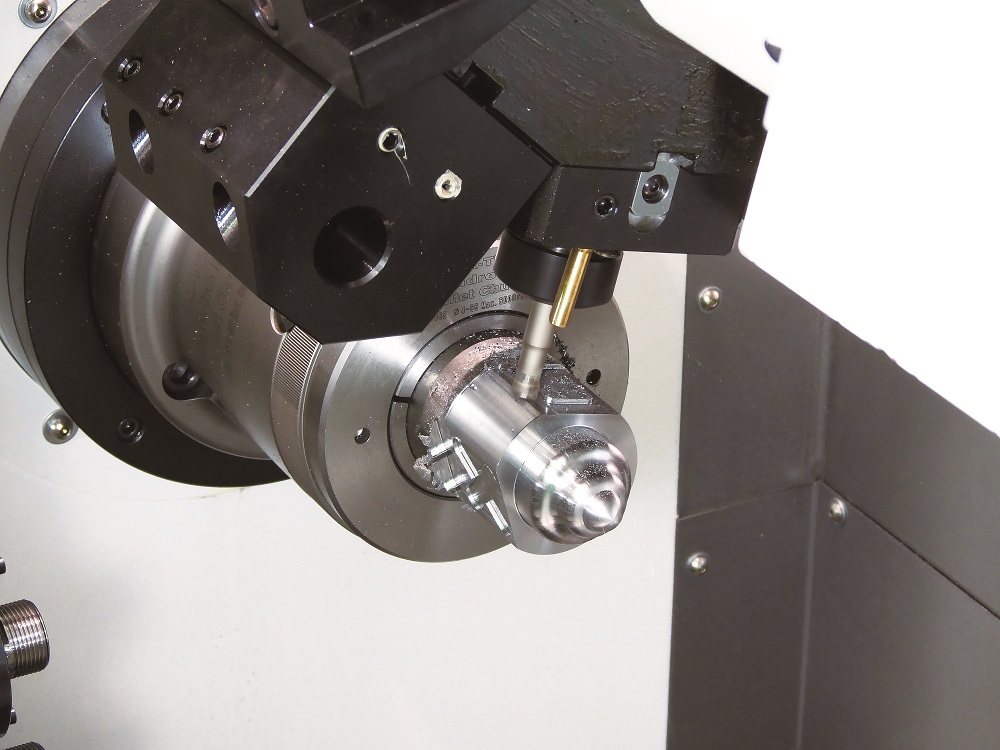

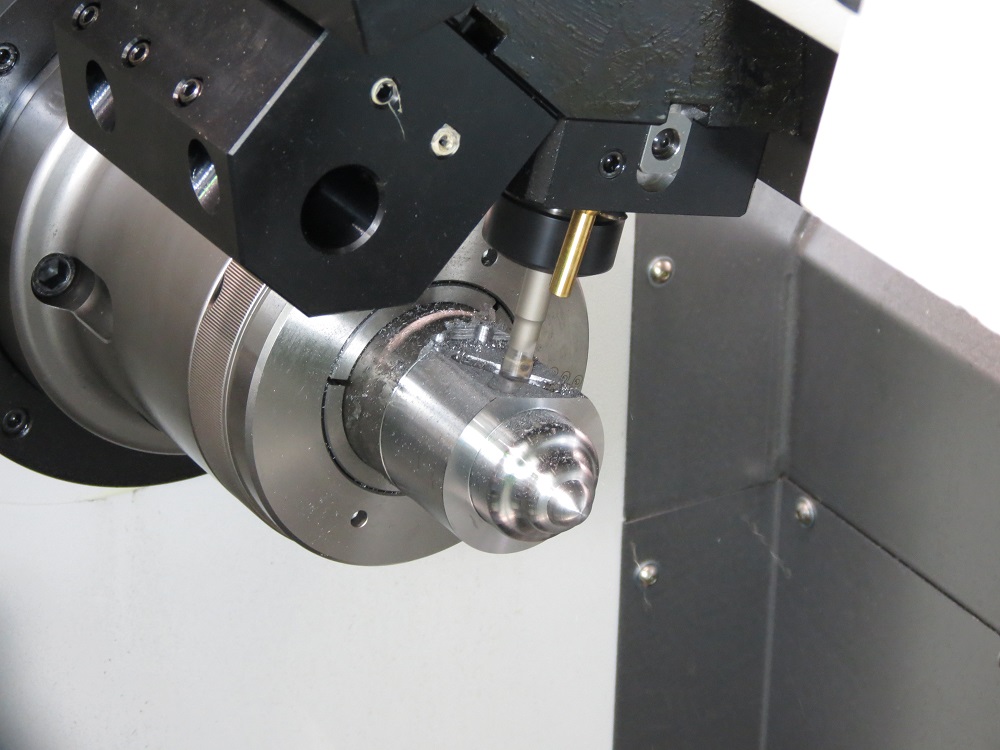

• Sub Spindle – 7.5 HP integral motor, 42 mm collet capacity, fully synchronized for accurate part handoff. - Hybrid Tooling System:

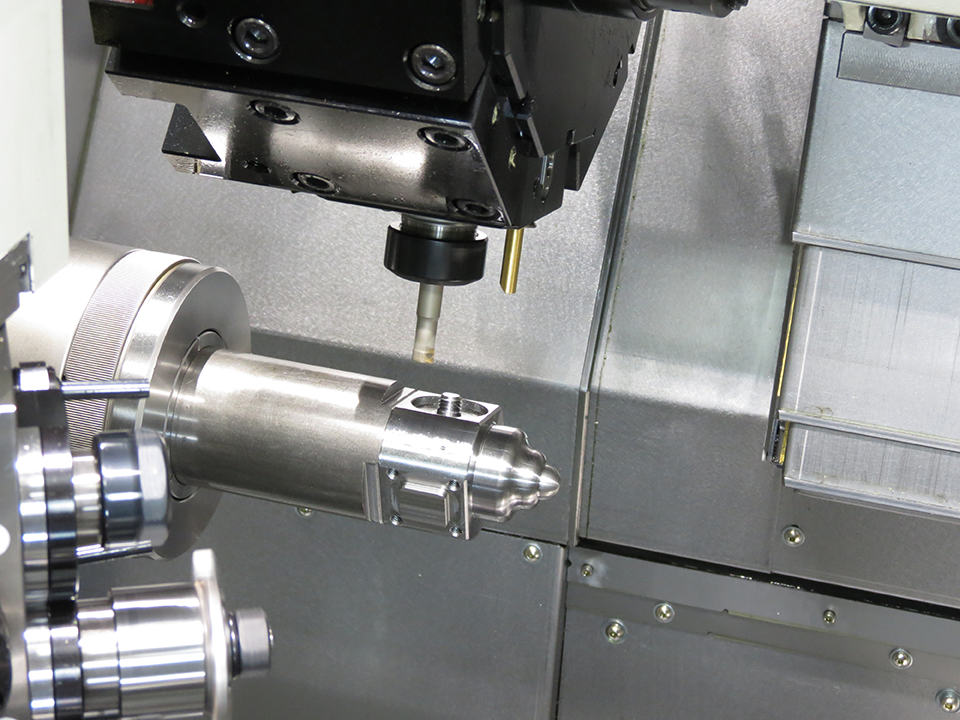

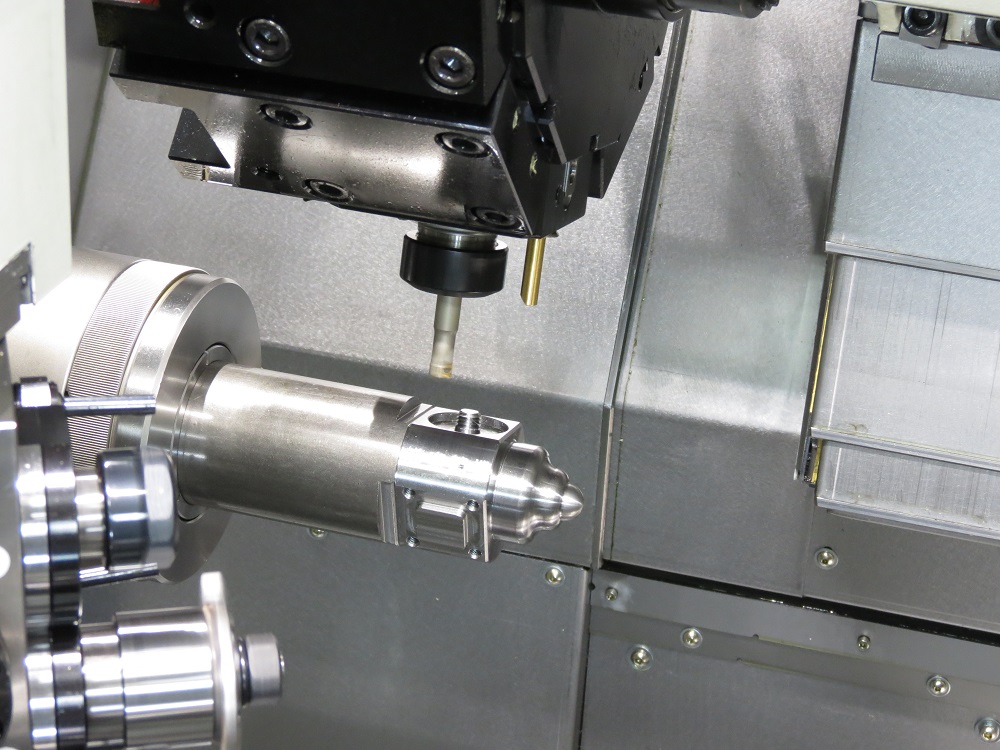

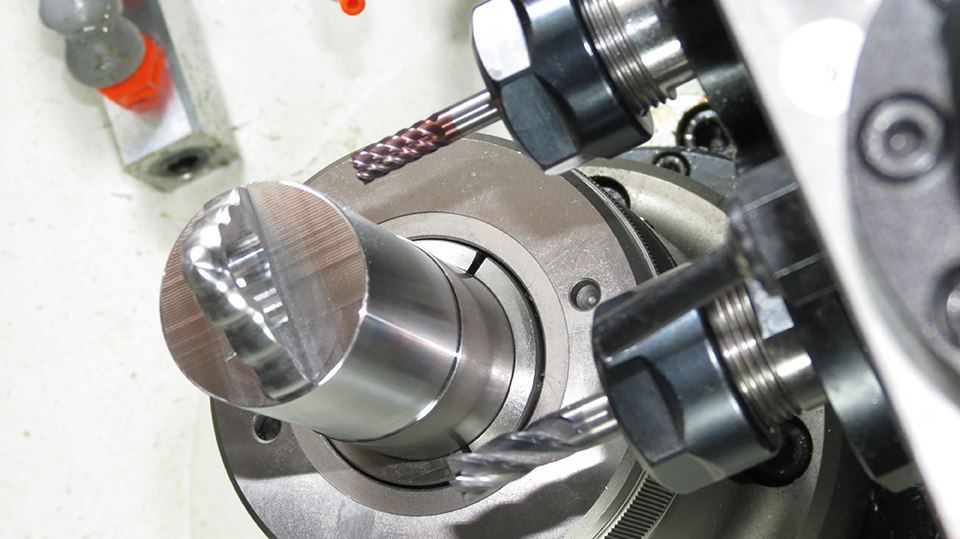

• 12-station BMT-55 live turret (5 HP motor, 80 mm Y-axis travel) with rigid hydraulic clamping and full live capability.

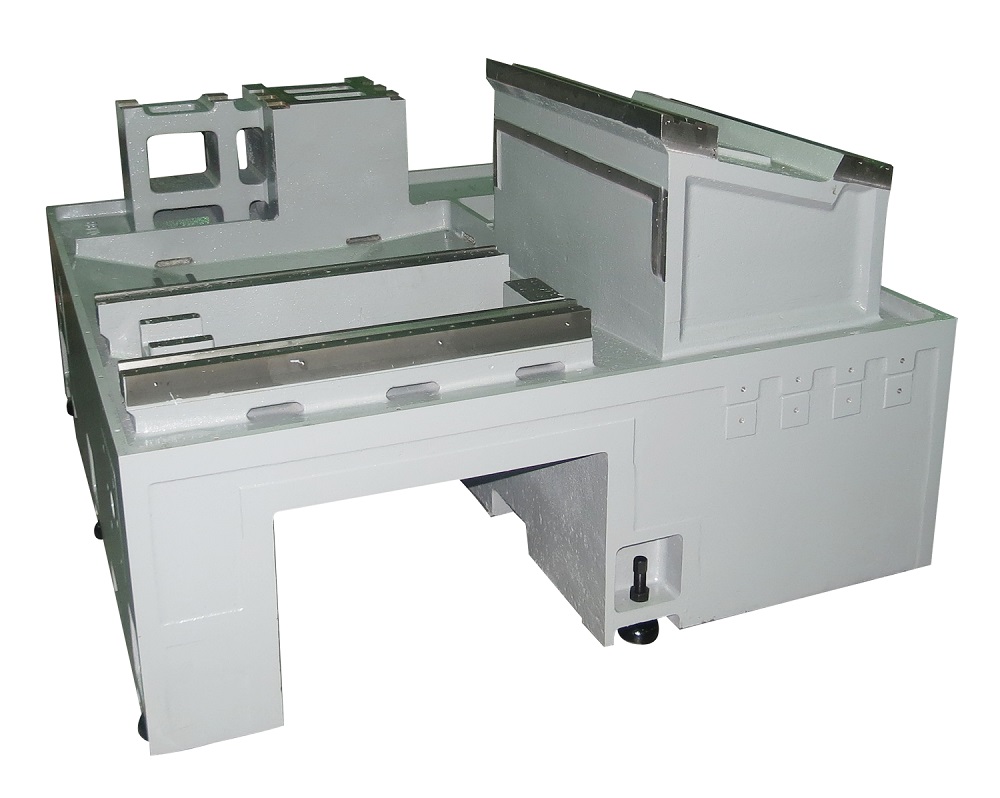

• 4-axis gang slide (X, Y, Z + B-axis) with 12 live tools powered by 2 HP motor for secondary milling and back-working operations. - Rigid Construction: One-piece Meehanite iron 75° slant bed; 35 mm Hiwin roller guideways; 32 mm double-anchored ballscrews ensure accuracy and thermal stability under load.

- High-Performance Control: Mitsubishi M830S with 15″ LCD touchscreen; Fanuc OiT-F Plus optional. Includes 3D graphics, Ethernet connectivity, and SSS high-finish control.

- Cycle-Time Efficiency: 1181 ipm rapid traverse rates and simultaneous multi-axis motion reduce setup and cut times.

- Automation-Ready: Standard bar feeder interface, parts catcher, parts conveyor, chip conveyor, and 400 PSI high-pressure coolant pump included.

- Service & Reliability: 12-month machine warranty and 3-year Mitsubishi CNC warranty supported by Absolute Machine Tools’ nationwide service network.

Specifications

| Item / Model |

T8 COMPACT

Request a Quote |

T8 MILL

Request a Quote |

T8 Twin Y

Request a Quote |

T8 HYBRID

Request a Quote |

|---|---|---|---|---|

|

Main Spindle Capacity | ||||

|

Swing over Bed |

19.7″ |

19.7″ |

19.7″ | |

|

Swing over Cross Slide |

11.8″ |

11.8″ |

11.8″ |

11.8″ |

|

Max Bar Working Capacity |

2.56″ (65mm) |

2.56″ (65mm) |

2.56″ (65mm) |

2.56″ (65mm) |

|

Max Turning Length |

13.8″ |

13.8″ |

13.8″ |

13.8″ |

|

Spindle Speed Range |

4,000 RPM |

4,000 RPM |

4,000 RPM |

4,000 RPM |

|

Spindle Motor |

20 HP Integral Motor |

20 HP Integral Motor |

20 HP Integral Motor |

15 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

.001° |

.001° |

|

Sub-Spindle Capacity | ||||

|

Max Bar Working Capacity |

1.65″ (42mm) |

1.65″ (42mm) | ||

|

Max Turning Length |

13.2″ |

13.2″ | ||

|

Spindle Speed Range |

4,000 RPM |

4,000 RPM | ||

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor | ||

|

C-Axis Increment |

.001° |

.001° | ||

|

Travel and Feed | ||||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

1,181″/min. |

1,181″/min. |

|

Tooling System (Main) | ||||

|

Tooling Type |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

BMT-55 Servo Turret |

|

Number of Tools |

12 |

12 |

12 |

12 |

|

Number of Live Tool Stations |

12 |

12 |

12 | |

|

Square Shank Size |

1″ (25mm) |

1″ (25mm) |

1″ (25mm) |

1″ (25mm) |

|

Boring Bar Capacity |

1.25″ (25mm) |

1.25″ (25mm) |

1.25″ (25mm) |

1.25″ (25mm) |

|

Turret Index Time |

.3 Seconds / Station |

.3 Seconds / Station |

.3 Seconds / Station |

.3 Seconds / Station |

|

Live Tool Spindle Motor |

5 HP |

5 HP |

5 HP | |

|

Live Tool Spindle Speed |

4,000 RPM |

4,000 RPM |

4,000 RPM | |

|

Tooling System (Sub) | ||||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change | |||

|

Number of Turning Tools |

5 O.D. / 9 I.D. | |||

|

Square Shank Size |

.75″ (20mm) | |||

|

Boring Bar Capacity |

.75″ (ER-20) | |||

|

B-Axis |

360° | |||

|

B-Axis Index Time |

.3 Seconds 90° / 6 Seconds 360° | |||

|

Number of Live Tools |

12 | |||

|

Live Tool Spindle Motor |

2 HP | |||

|

Live Tool Spindle Speed |

4,000 | |||

|

Live Tool Shank |

ER-20 Collet | |||

|

Tailstock | ||||

|

Body Travel (manual) |

15.7″ |

15.7″ | ||

|

Quill Travel (programmable hydraulic) |

3.15″ |

3.15″ | ||

|

Quill Diameter |

2.95″ |

2.95″ | ||

|

Quill Taper |

MT#4 |

MT#4 | ||

|

General | ||||

|

CNC Control |

Mitsubishi M80A |

Mitsubishi M80A |

Mitsubishi M80A |

Mitsubishi M830S |

|

Machine Dimensions with Chip Conveyor |

128″ x 65″ x 69″ |

128″ x 65″ x 69″ |

132″ x 65″ x 69″ |

135″ x 80″ x 77″ |

|

Machine Weight |

12,040 lbs. |

12,500 lbs. |

12,540 lbs. |

13,420 lbs. |

Benefits for Metal Cutting Manufacturers

The Quicktech T8 Hybrid allows parts manufacturers to machine complete components in a single setup—eliminating multiple machines, operators, and part-handling steps. Its rigid Meehanite-cast 75° slant bed and 35 mm roller-type linear guideways provide exceptional stability, rigidity, and vibration control for superior accuracy and surface quality.

Both main and sub-spindles feature synchronized C-axes for seamless part transfer, ensuring tight concentricity and reduced cycle times. The Mitsubishi M830S CNC control, equipped with Super Smooth Surface (SSS) and High-Speed/High-Accuracy Modes I & II, produces mirror-finish precision on even the most demanding materials.

Manufacturers gain higher reliability, extended tool life, and lower cost per part—ideal for contract shops focused on uptime, repeatability, and throughput.