QuickTECH i-42 / i-60 Ultimate 10-Axis Twin Spindle Mill/Turn Centers with Dual B-Axes

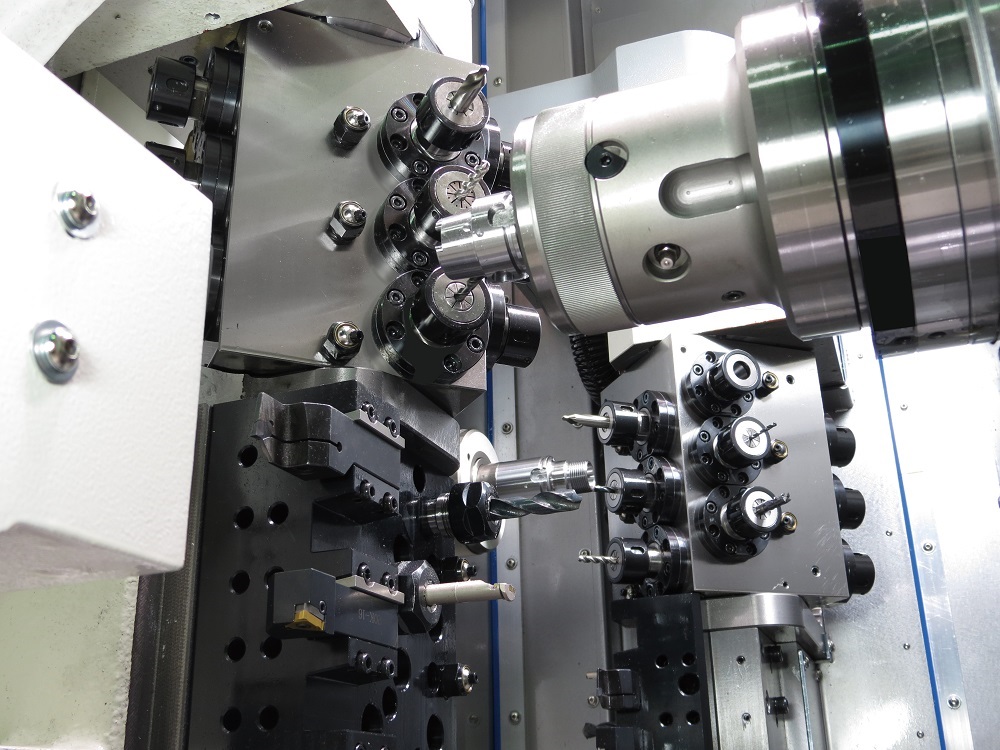

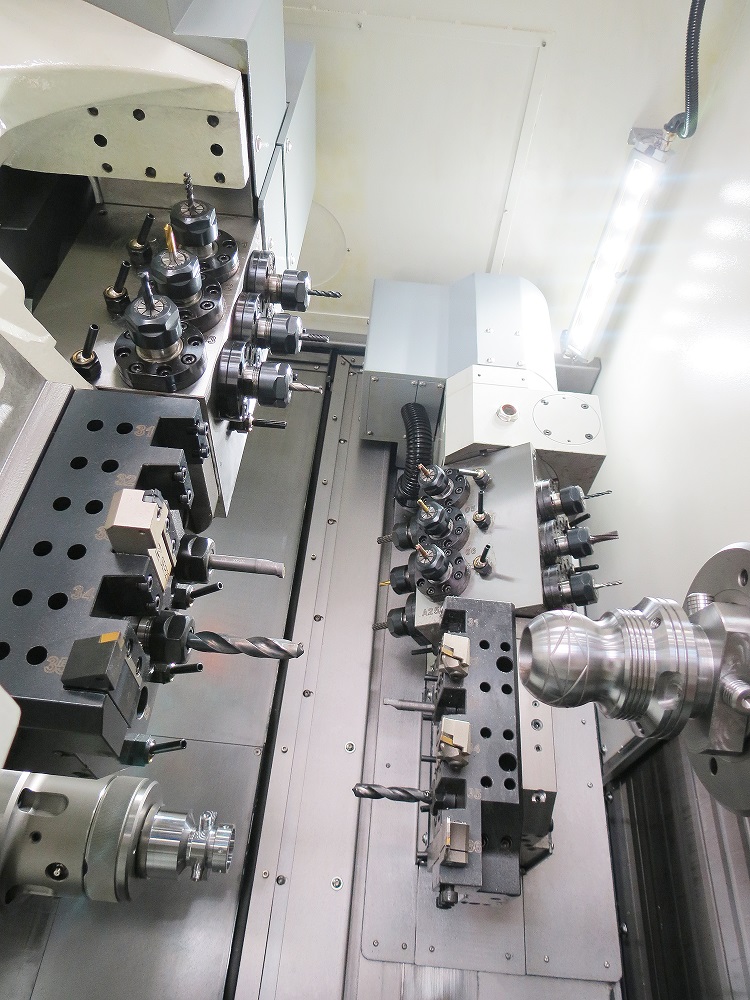

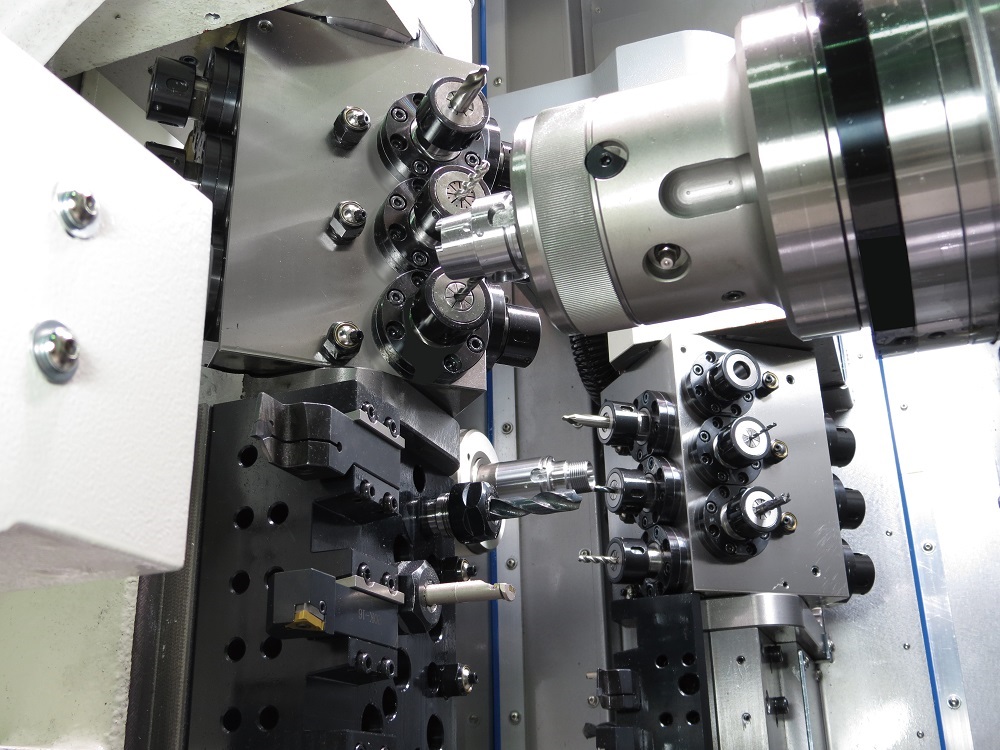

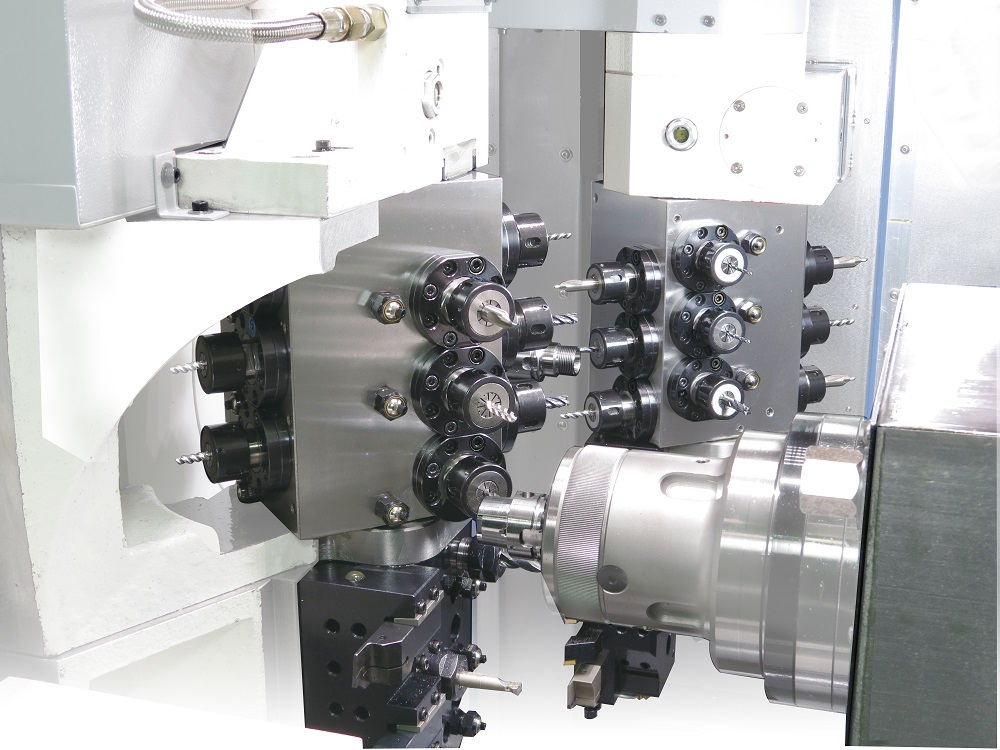

The QuickTECH i-42 / i-60 Ultimate bar processing machines provide complete part machining including complex milling functions. The compact, high precision, high production CNC mill/turn centers are cast from rigid Meehanite iron. Available in both 42 mm (1.65″) and 60 mm (2.36″) bar capacities, the i-42/i-60 features 10 axes, 2 turning spindles, 2 milling spindles, 2 B-axes, and a total capacity of 56 tools. A 4 axis (X,Y,Z,B) gang type vertical tool post serves each C-axis spindle.

Turning Spindles

The main spindle has a 15 HP high torque motor. The sub-spindle is equipped with a 7.5 hp high torque integral motor for backworking. The main spindle has a 42mm bar capacity (60mm for i-60) and the sub-spindle has 30mm (1.18″) bar capacity. Both spindles feature a full continuous C-axis with braking system and are both standard with 42mm DIN-173E-42B collet chucks (60mm DIN-185E-60B for i-60). The main and sub-spindle are synchronized for fast and accurate part transfer. Both spindles employ P4 high precision bearings for stability and heavy cutting ability.

Tooling System

A 4-axis gang tooling system consisting of linear X,Y, and Z axes plus a rotary B-axis serves each spindle. The main tool post features 6 O.D. turning tools, 5 I.D. turning tools, and 12 live tools. The sub-tool post features 5 O.D. turning tools, 9 I.D. turning tools, and 12 live tools. The live tools are powered by a 2 HP spindle motor and are mounted in a continuous 360˚ B-axis. Each tool post has a Y-axis for off-center milling operations. Tool change time is near zero. Rigid tapping is standard. In addition, QuickTECH’s standard tooling system is Kennametal KM-25 quick change, and KM-25 bases are supplied with the machine for O.D. turning tools.

Specifications

| Item / Model |

i-42

Request a Quote |

i-60

Request a Quote |

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar Working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std.) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Sub-Spindle Capacity | ||

|

Max Bar Working Capacity |

1.65″ |

1.65″ |

|

Max Turning Length |

3.94″ |

3.94″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

Tooling System (Main) | ||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 cut-off) & 5 I.D. |

6 O.D. (5 + 1 cut-off) & 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ED-20) |

.75″ (ED-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / .6 Seconds 360° |

.3 Seconds 90° / .6 Seconds 360° |

|

Number of Live Tools |

12 |

12 |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

Tooling System (Sub) | ||

|

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

5 O.D. & 9 I.D. |

5 O.D. & 9 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis |

360° |

360° |

|

B-Axis Index Time |

.3 Seconds 90° / 6 Seconds 360° |

.3 Seconds 90° / 6 Seconds 360° |

|

Number of Live Tools |

12 |

12 |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

General | ||

|

CNC Control |

Mitsubishi M830S |

Mitsubishi M830S |

|

Machine Dimensions with Chip Conveyor |

138″ x 75″ x 75″ |

138″ x 75″ x 75″ |

|

Machine Weight |

9,240 lbs. |

9,240 lbs. |