Quicktech ECO Series – 4 & 5 Axis Mill-Turn Centers with Tailstocks

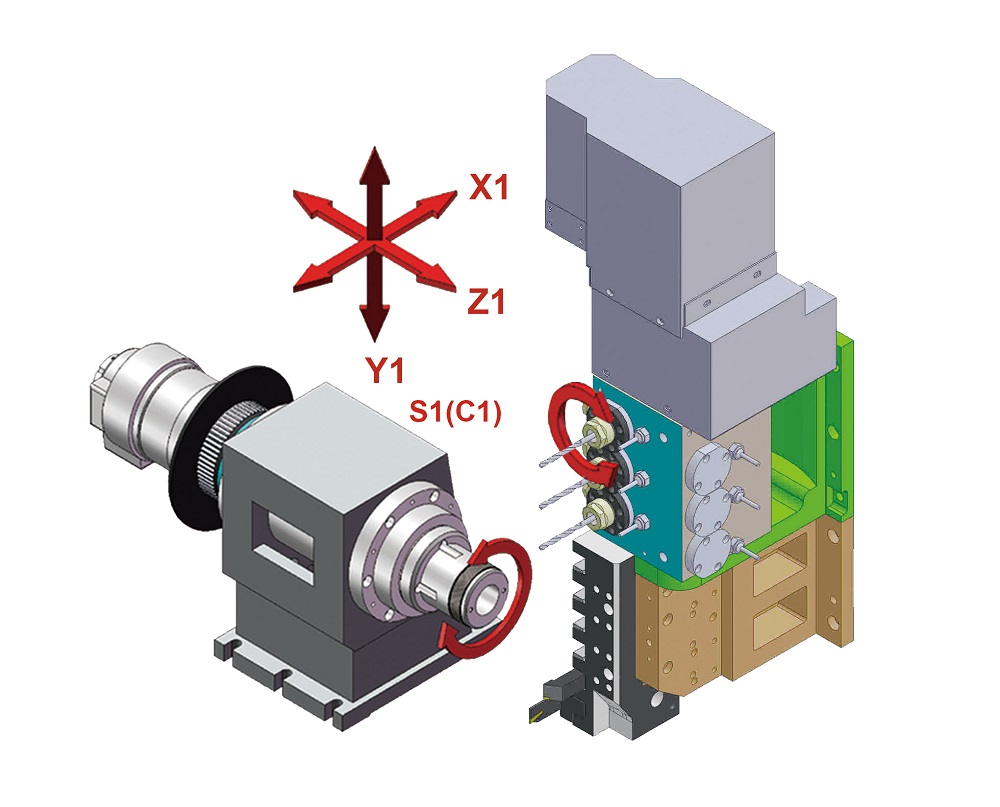

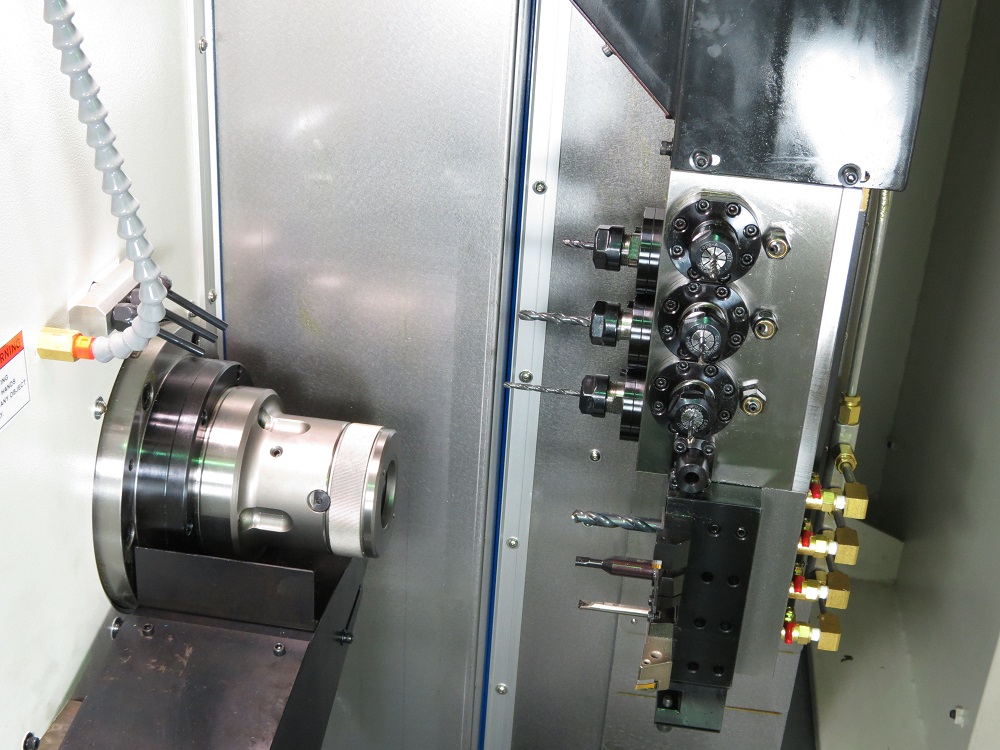

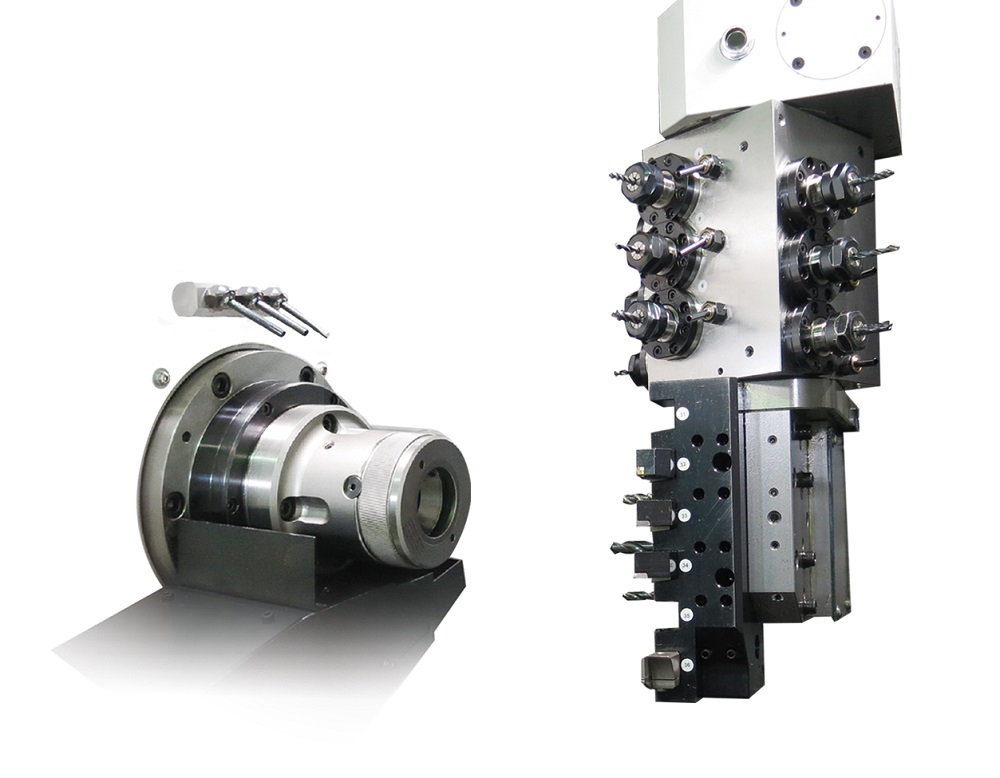

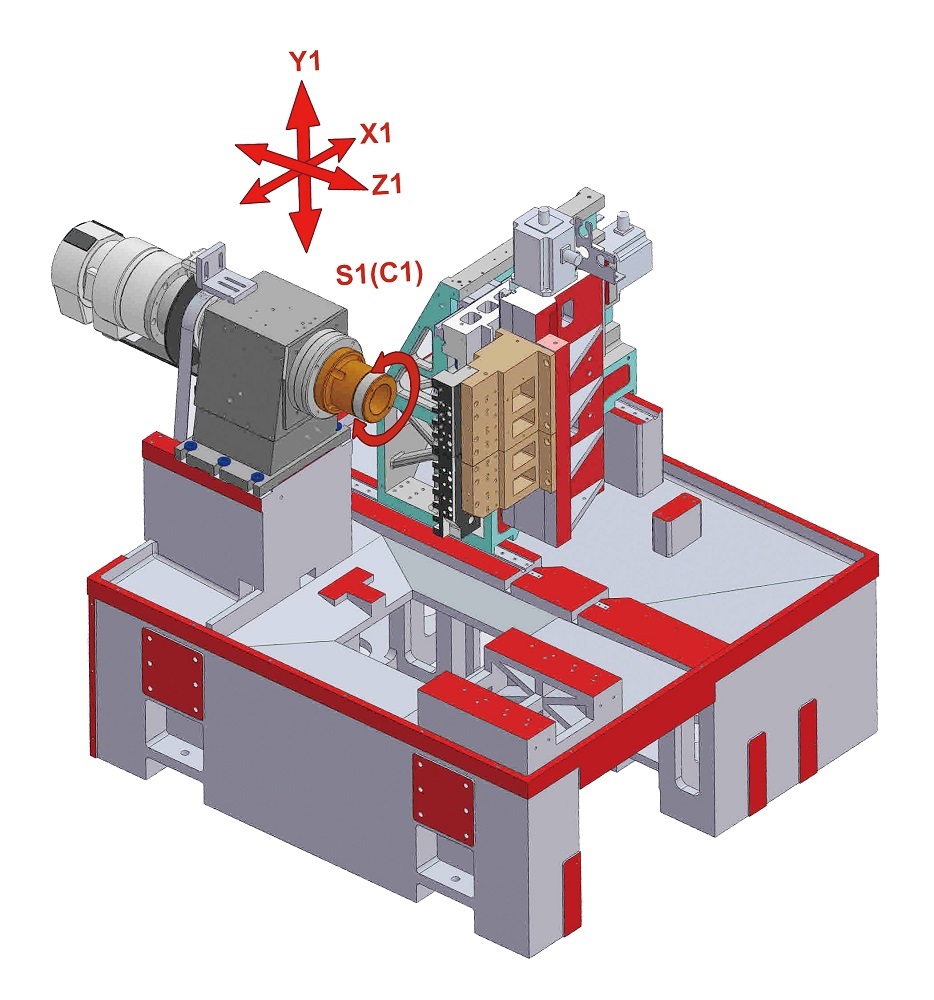

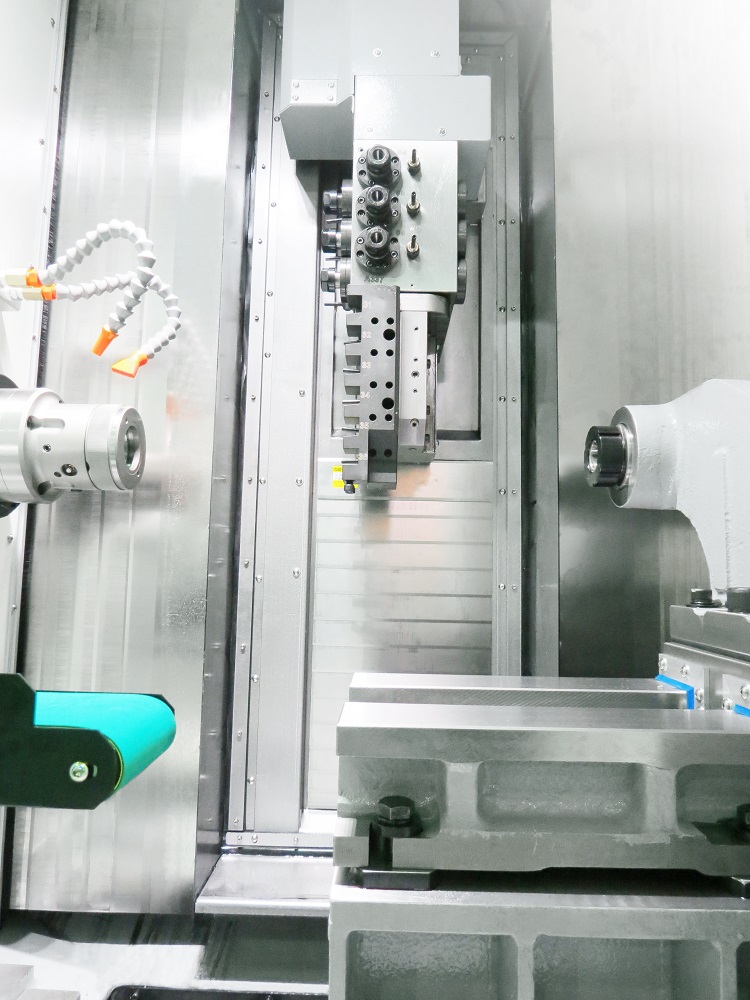

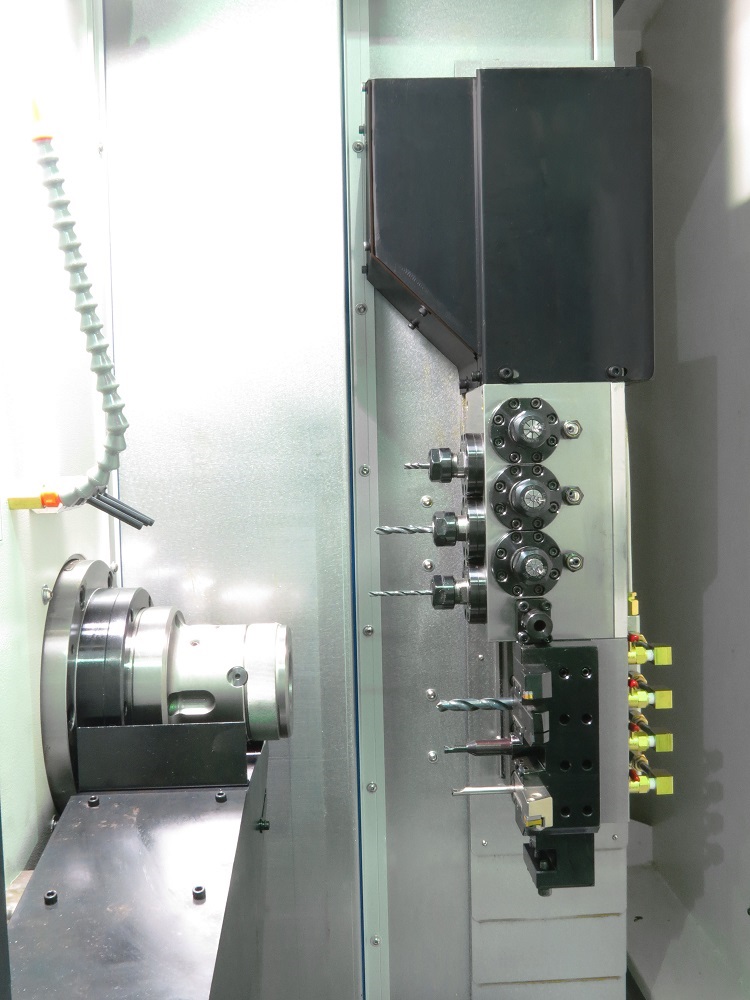

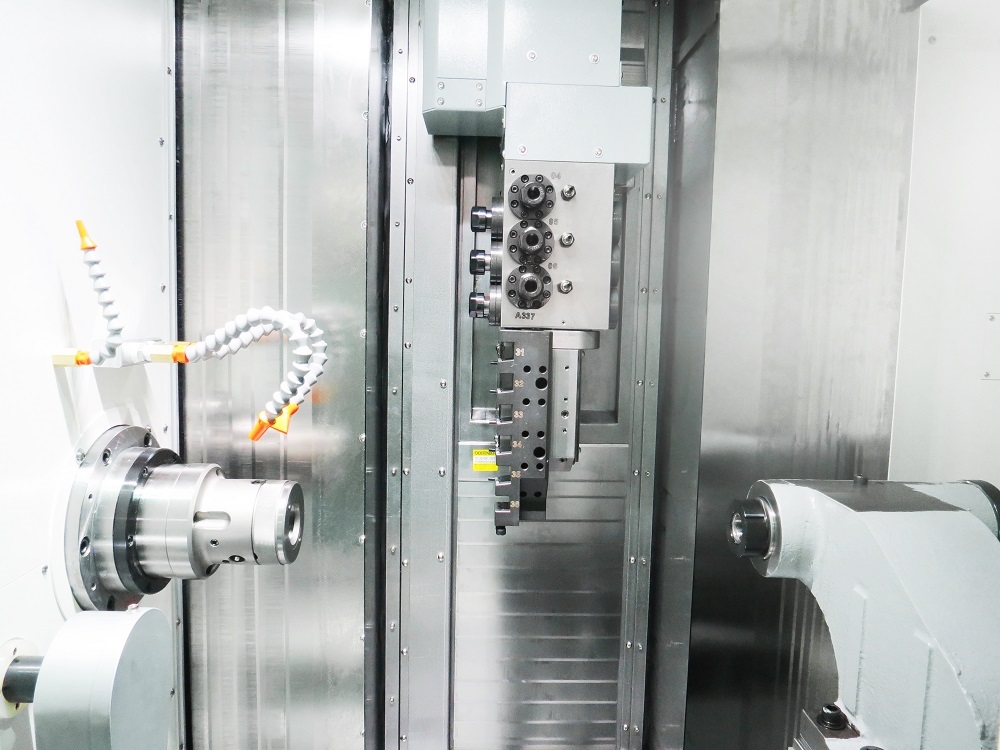

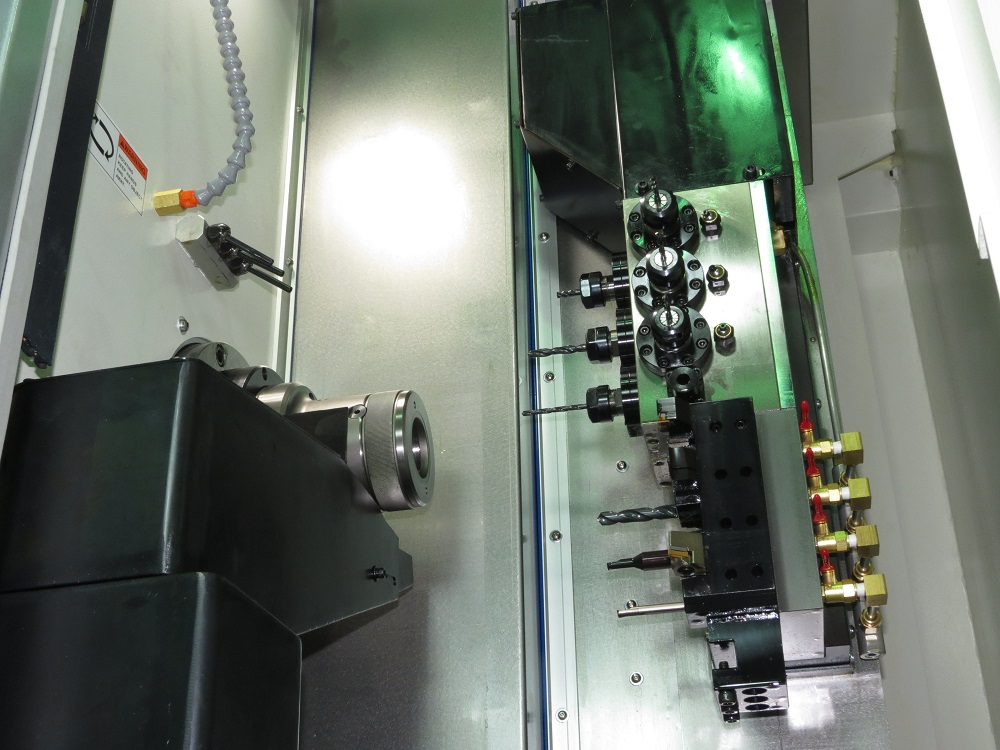

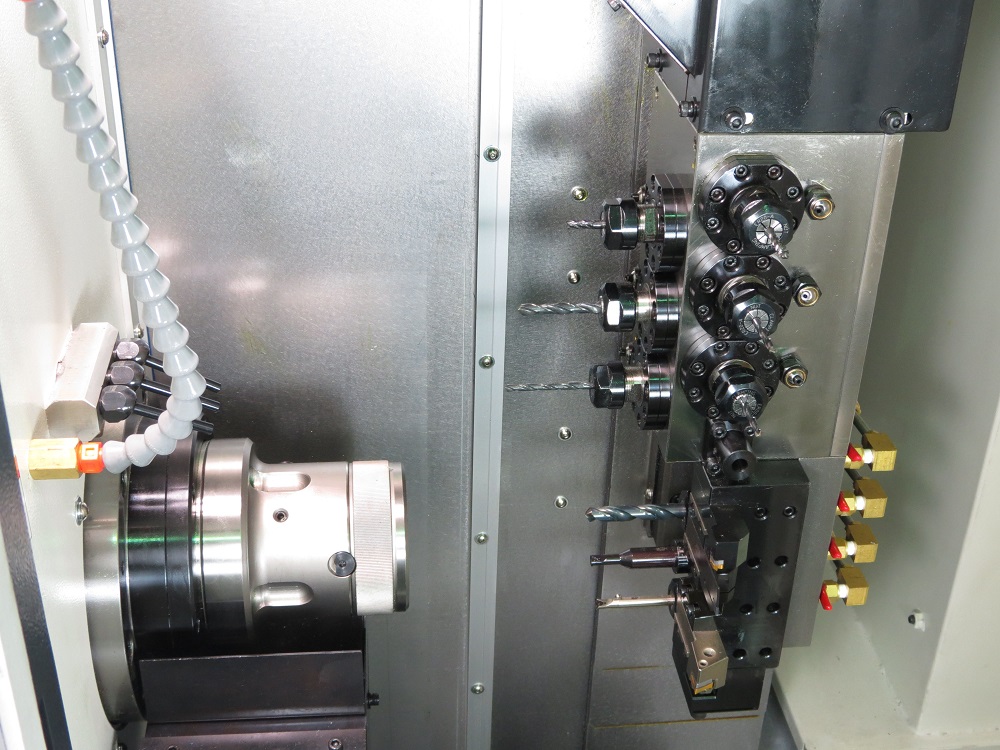

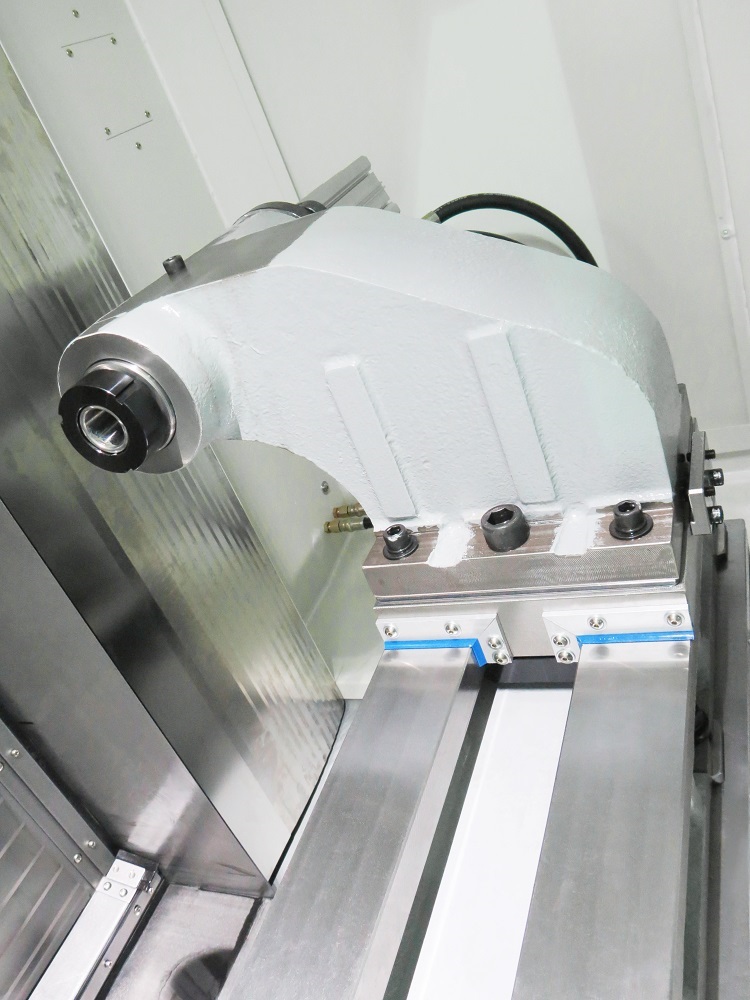

The Quicktech ECO Series — available in i-42 and i-60 models — delivers high-precision, high-production performance in a compact, cost-effective turn-mill center. Cast from Meehanite iron for exceptional rigidity and stability, each model offers complete single-operation part machining including complex milling, off-center drilling, and full contouring. With 4 axes standard and an optional 5th-axis B-head, the ECO Series provides unmatched machining flexibility for medical, automotive, aerospace, and general precision component manufacturers seeking to reduce cycle times and increase throughput.

Competitors include Miyano, Ganesh, and Doosan, but few can match the ECO’s blend of affordability, rigidity, and multitasking capability.

Key Features

Specifications

| Item / Model |

i-42 Eco

Request a Quote |

i-60 Eco

Request a Quote |

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar working Capacity |

1.65″ |

2.36″ |

|

Max Turning Length |

9.8″ |

9.8″ |

|

Spindle Speed Range (std.) |

6,000 RPM |

4,000 RPM |

|

Spindle Motor |

15 HP |

15 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Tailstock | ||

|

Quill Travel |

6.3″ |

6.3″ |

|

Tailstock Body Travel |

15.35″ |

15.35″ |

|

Programmable Tailstock (opt.) |

MT #5 |

MT #5 |

|

Spindle Nose |

A2-5 |

A2-5 |

|

Hole through Draw Tube |

1.181″ |

1.181″ |

|

Spindle Speed Range |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

7.5 HP Integral Motor |

7.5 HP Integral Motor |

|

C-Axis Increment |

.001° |

.001° |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

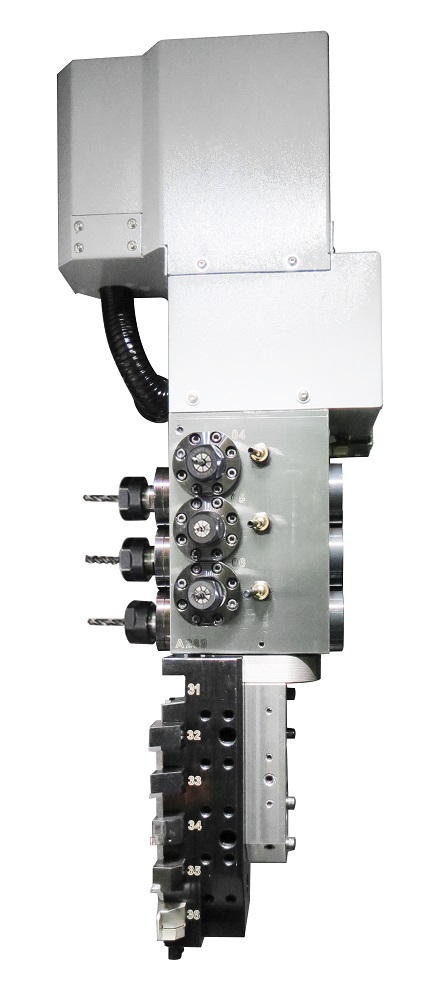

Tooling System | ||

|

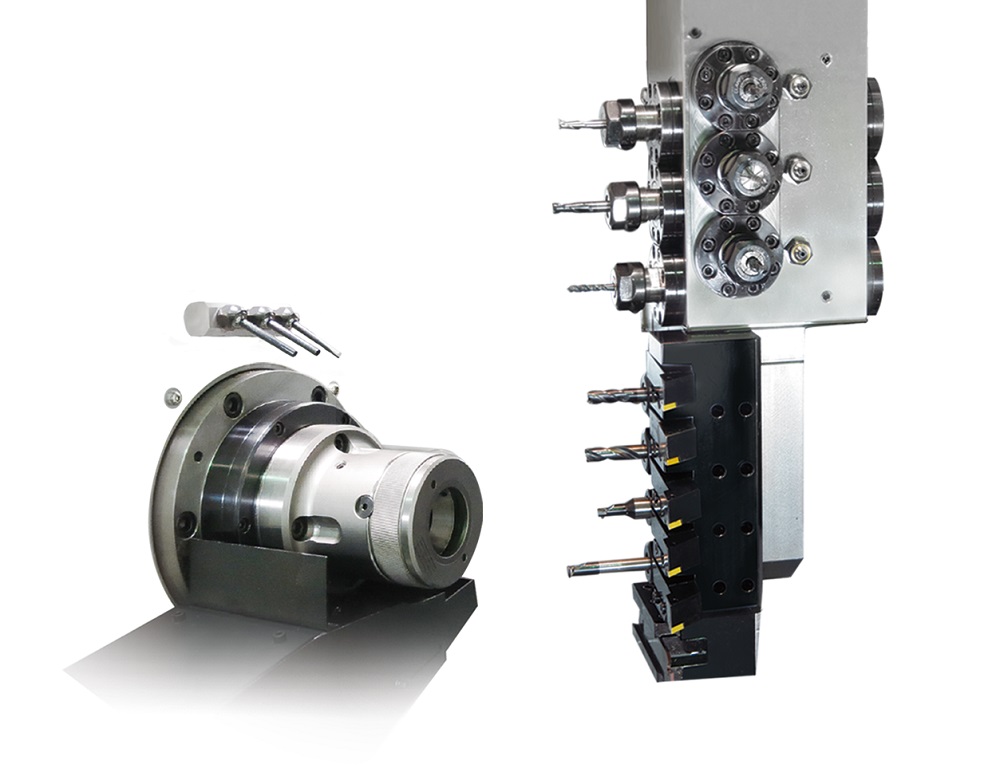

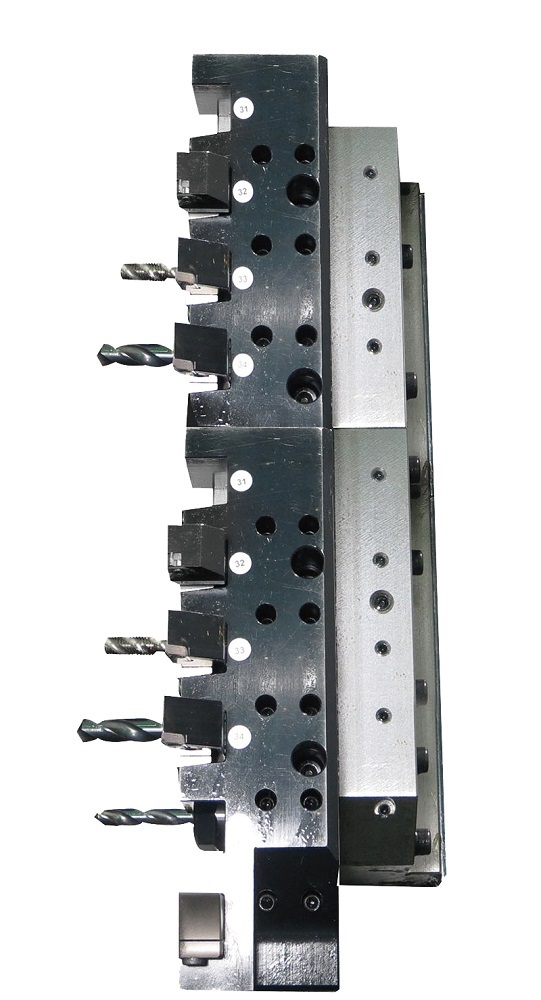

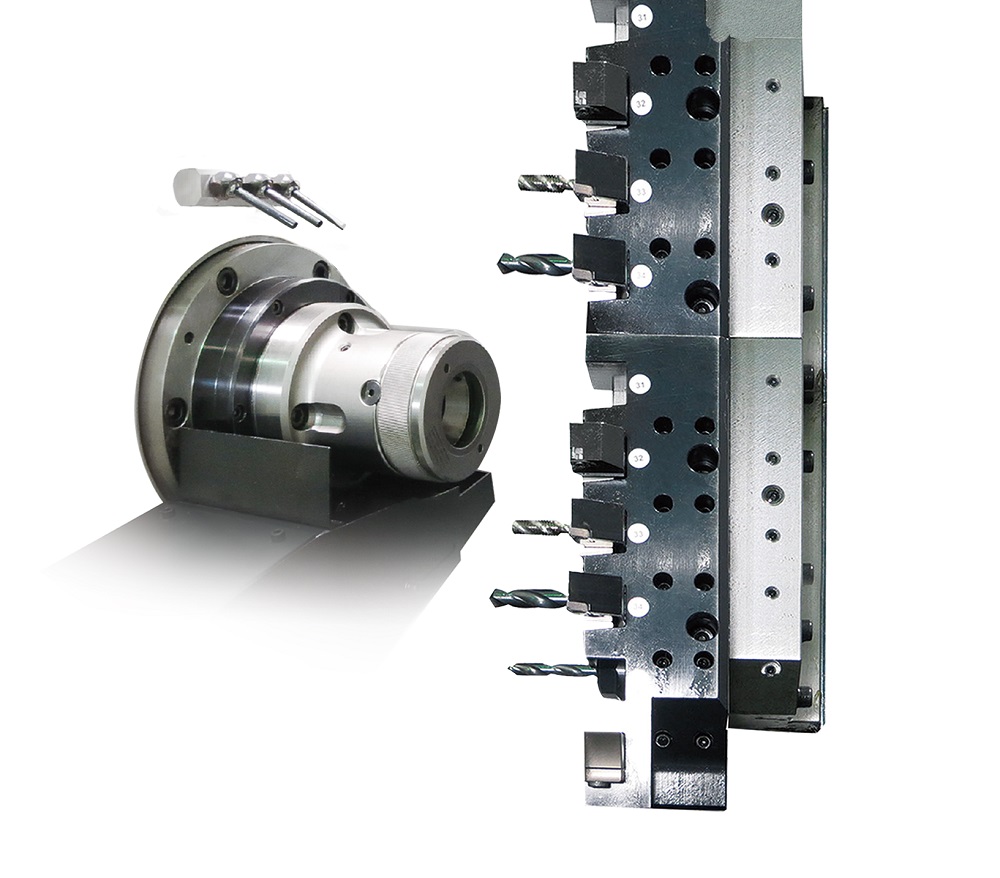

Tooling Type |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

Gang Tool / Servo Y-Axis / KM-25 Quick Change |

|

Number of Turning Tools |

6 O.D. (5 + 1 Cut-Off) / 5 I.D. |

6 O.D. (5 + 1 Cut-Off) / 5 I.D. |

|

Square Shank Size |

.75″ (20mm) |

.75″ (20mm) |

|

Boring Bar Capacity |

.75″ (ER-20) |

.75″ (ER-20) |

|

B-Axis (opt.) |

360° |

360° |

|

B-Axis Index Time (opt.) |

.3 Seconds 90° / .6 Seconds 360° |

.3 Seconds 90° / .6 Seconds 360° |

|

Number of Live Tools |

6 (12 with B-Axis) |

6 (12 with B-Axis) |

|

Live Tool Spindle Motor |

2 HP |

2 HP |

|

Live Tool Spindle Speed |

4,000 |

4,000 |

|

Live Tool Shank |

ER-20 Collet |

ER-20 Collet |

|

General | ||

|

Machine Dimensions with Chip Conveyor |

132″ x 60″ x 77″ |

132″ x 60″ x 77″ |

|

Machine Weight |

6,050 lbs. |

6,050 lbs. |

Benefits for Metal Cutting Manufacturers

Manufacturers benefit from the ECO Series’ powerful 15 HP main spindle and 2 HP live tooling drive, enabling heavy-duty turning and simultaneous milling operations with superior accuracy and finish. The true linear Y-axis and optional B-axis rotary tooling head perform complex milling on multiple planes in a single setup — ideal for reducing setups, operator handling, and overall cycle time.

Built-in C-axis synchronization, P4 high-precision spindle bearings, and 35 mm roller linear guideways ensure tight tolerances and ultra-fine surface finishes even under demanding conditions. These compact machines are engineered for reliability, easy automation integration, and low cost of ownership — providing a total solution that improves part accuracy, process stability, and profitability.