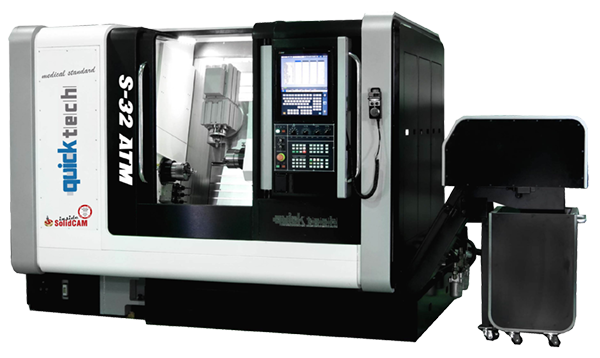

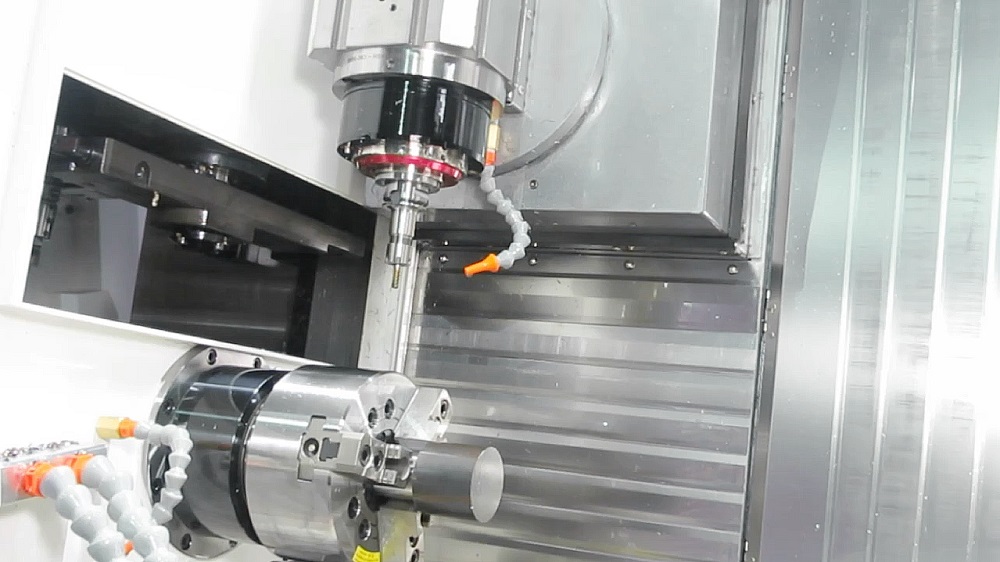

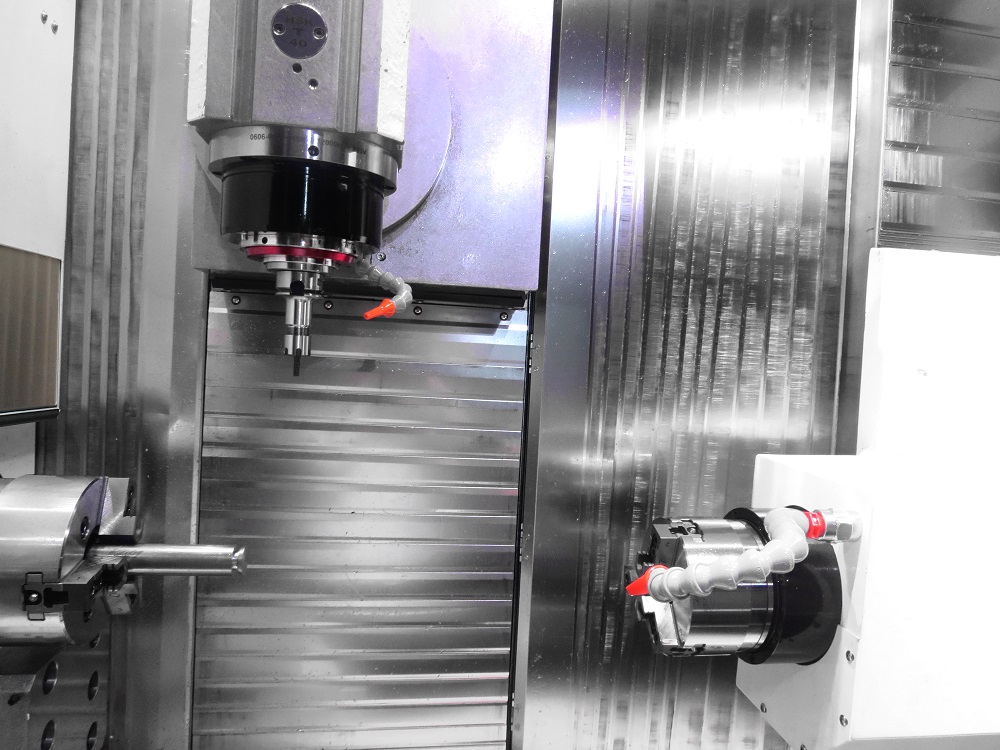

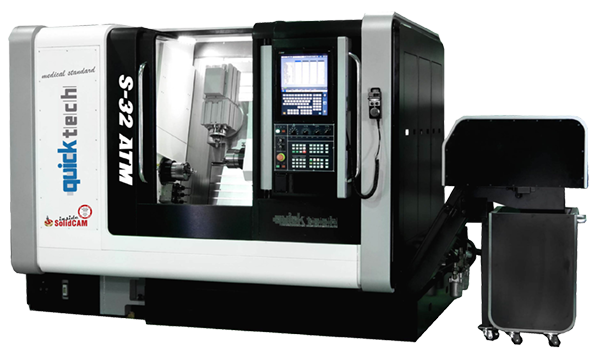

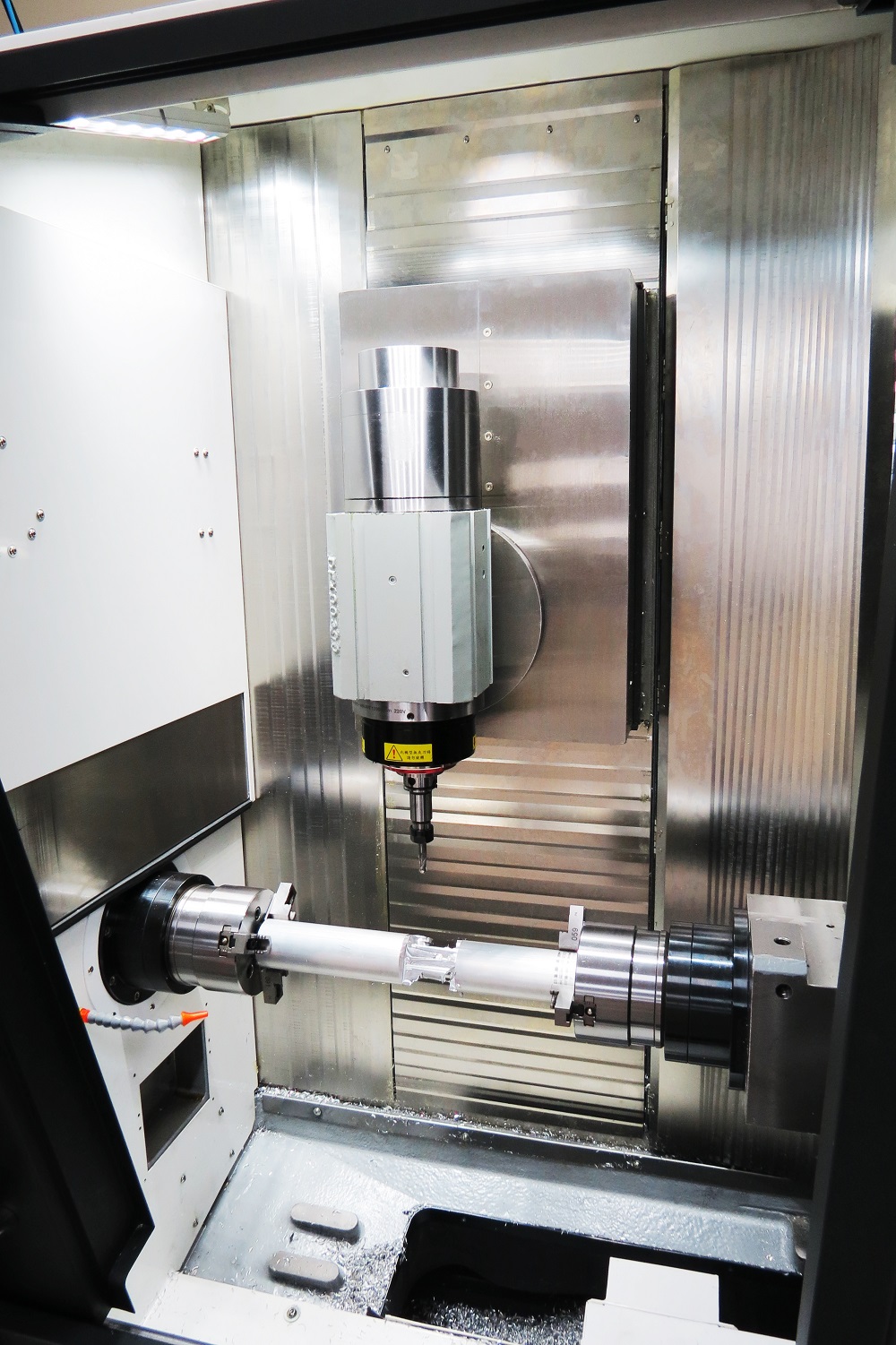

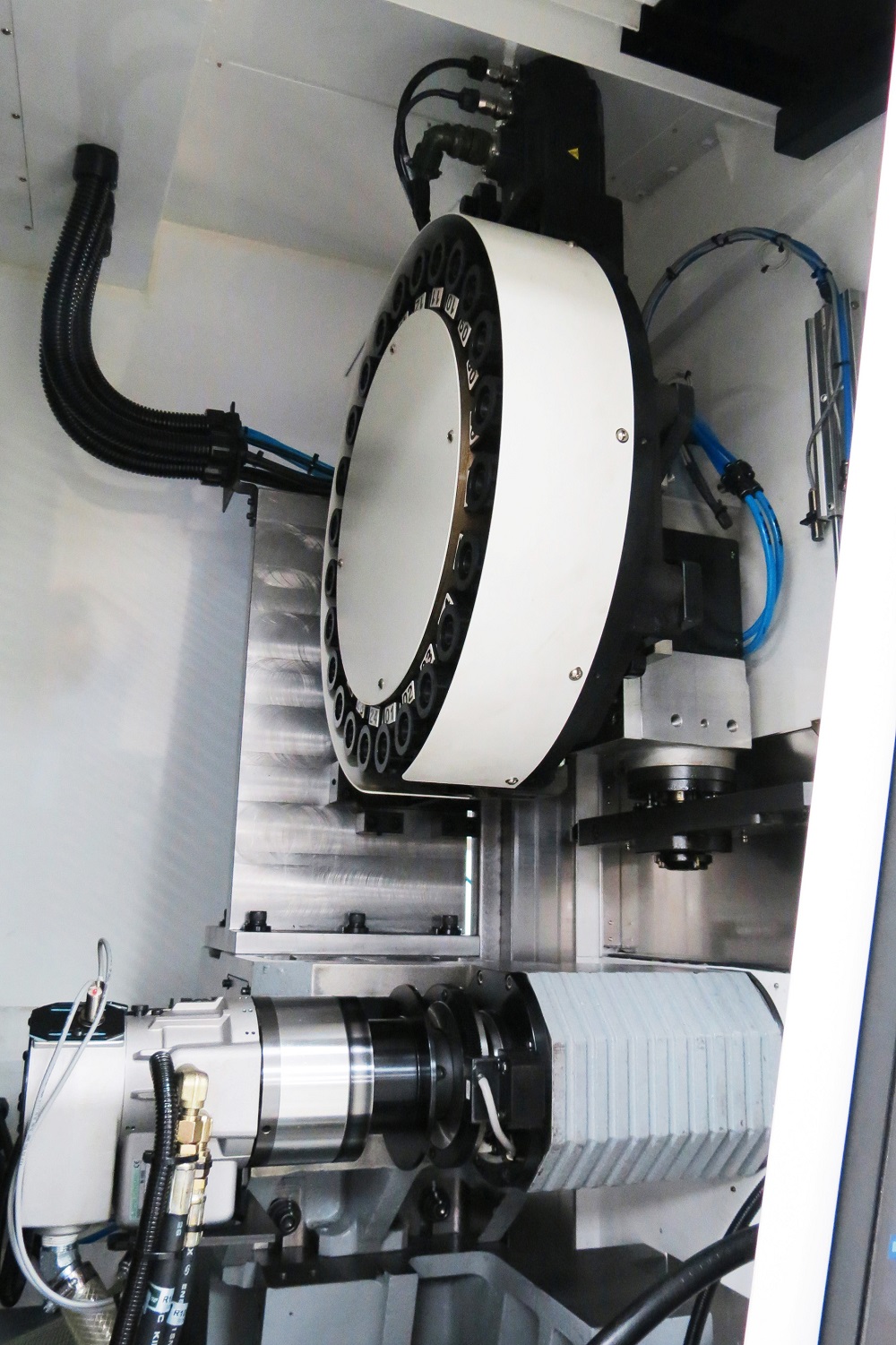

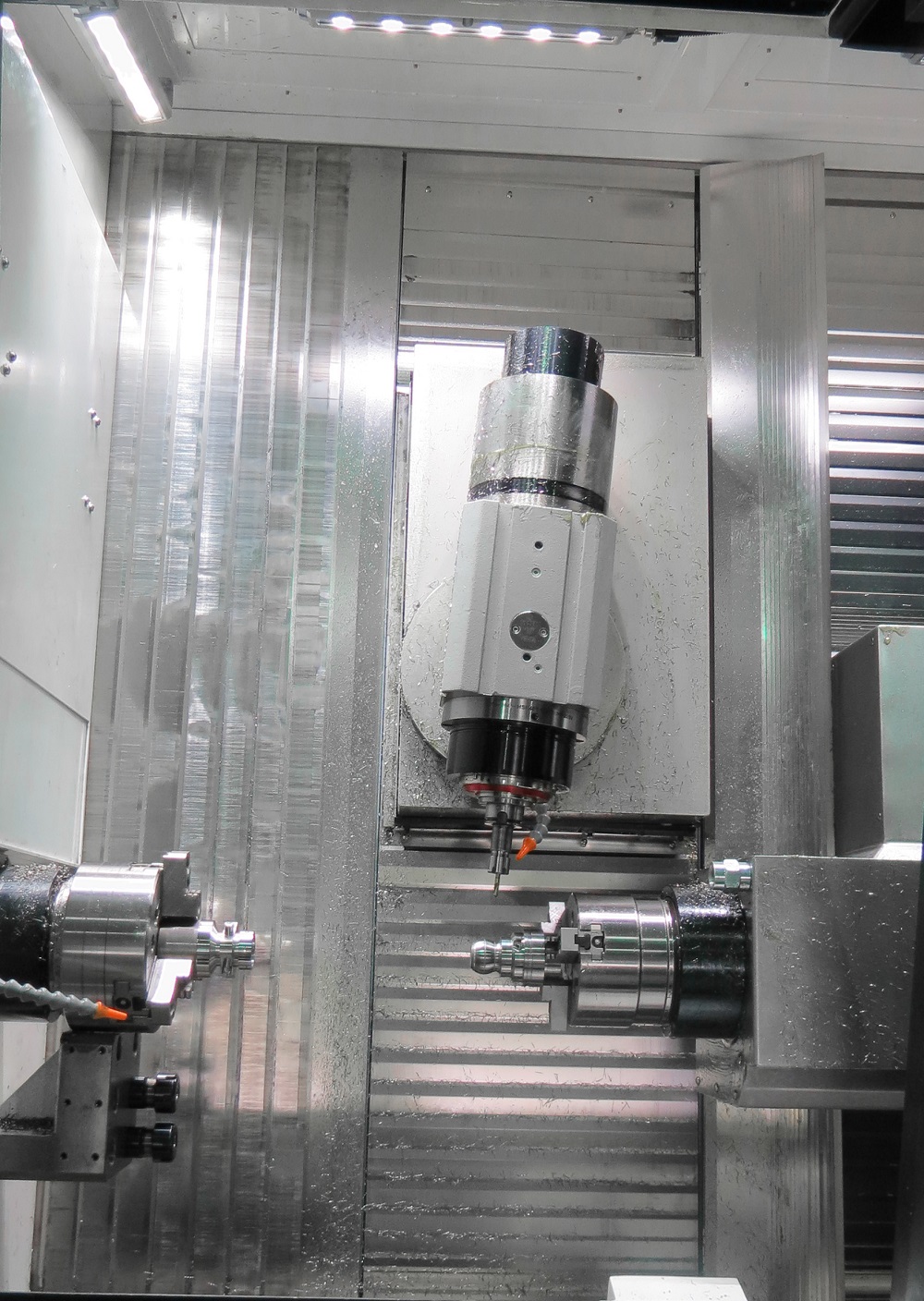

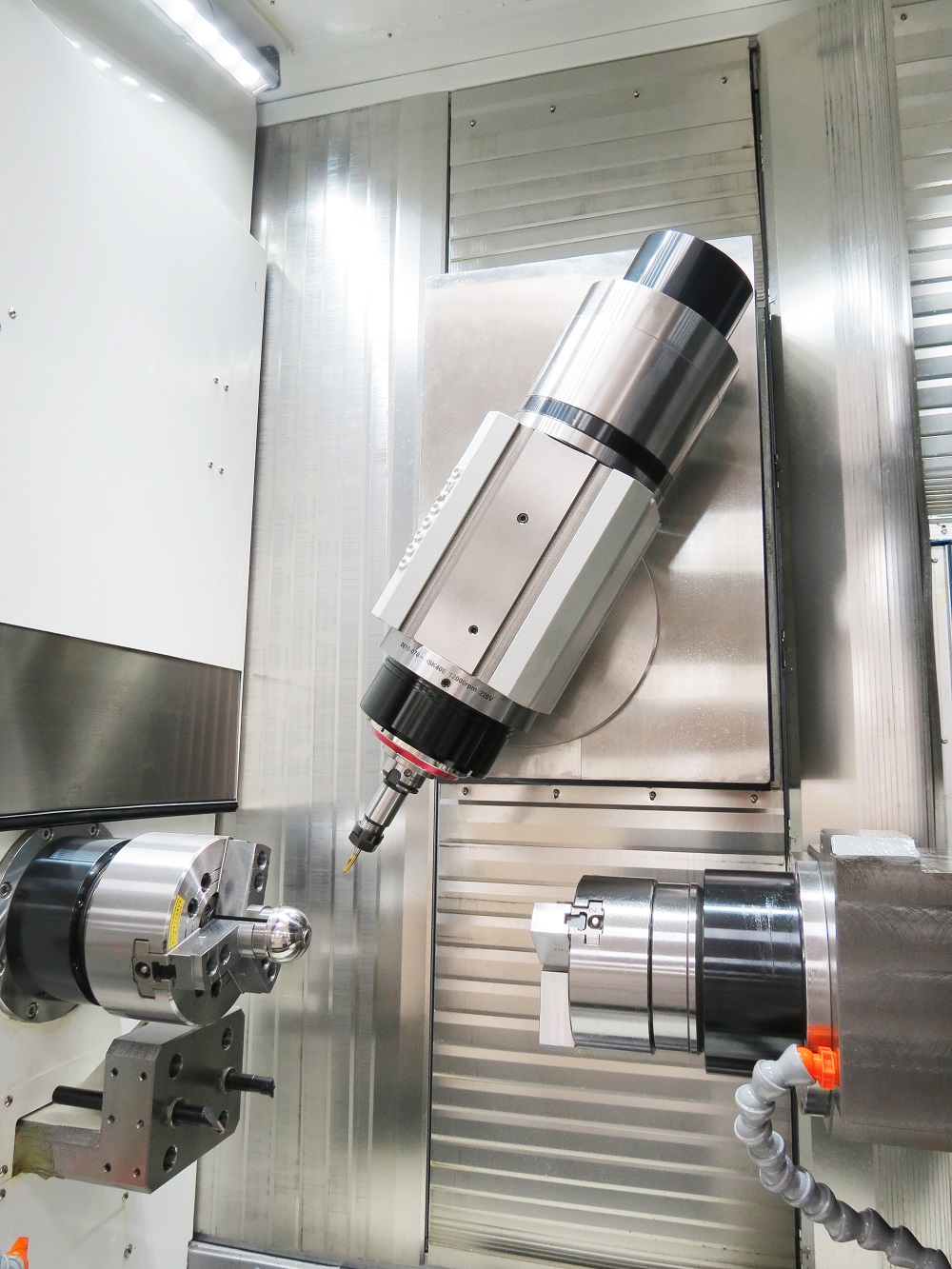

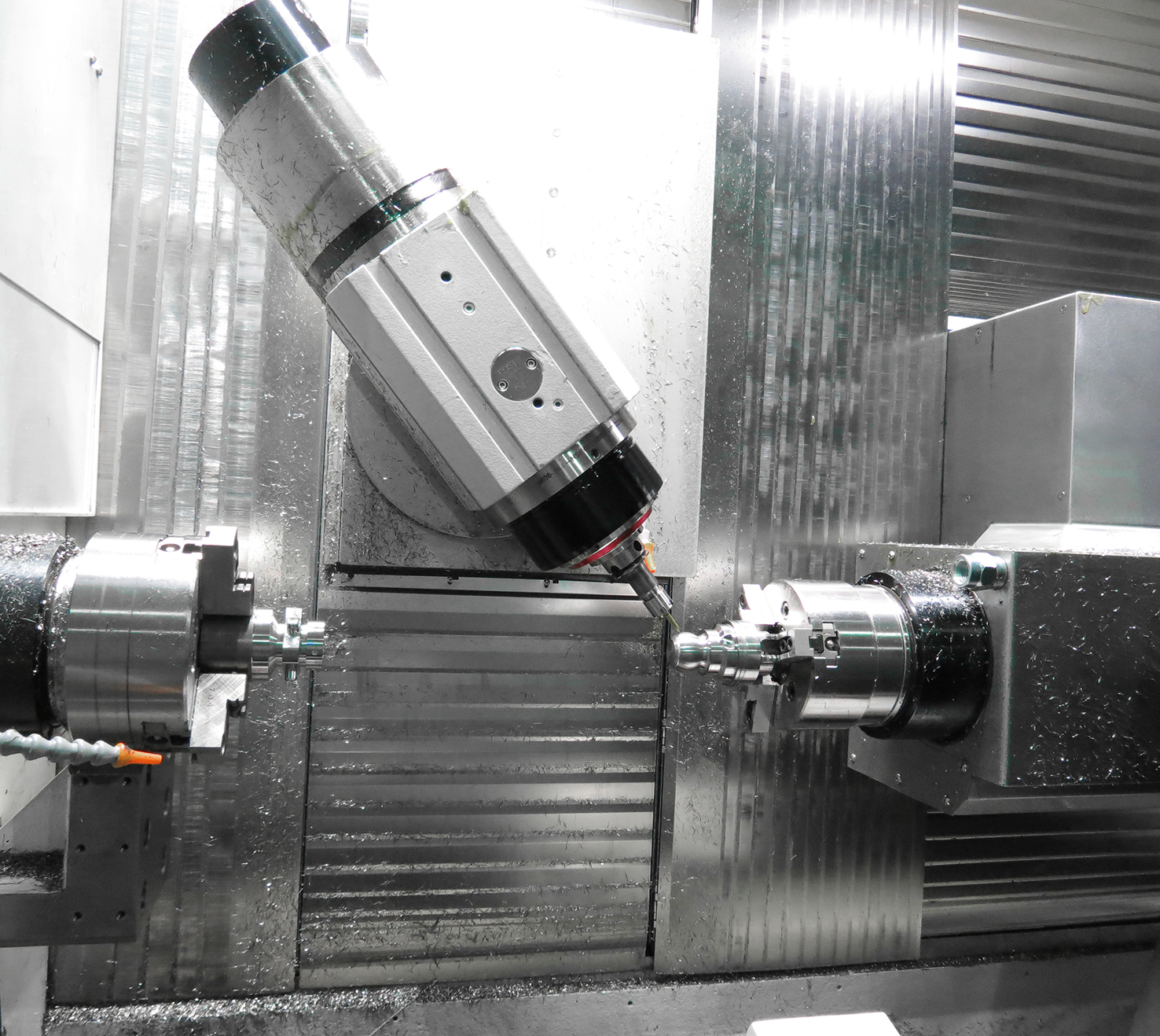

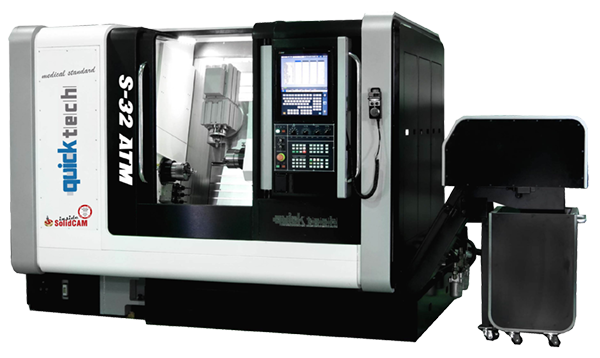

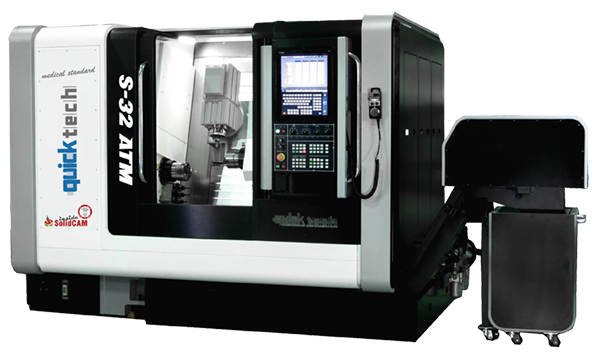

Quicktech S-ATM Series – 9-Axis Compact Twin Spindle Mill-Turn Centers with B-Axis and ATC

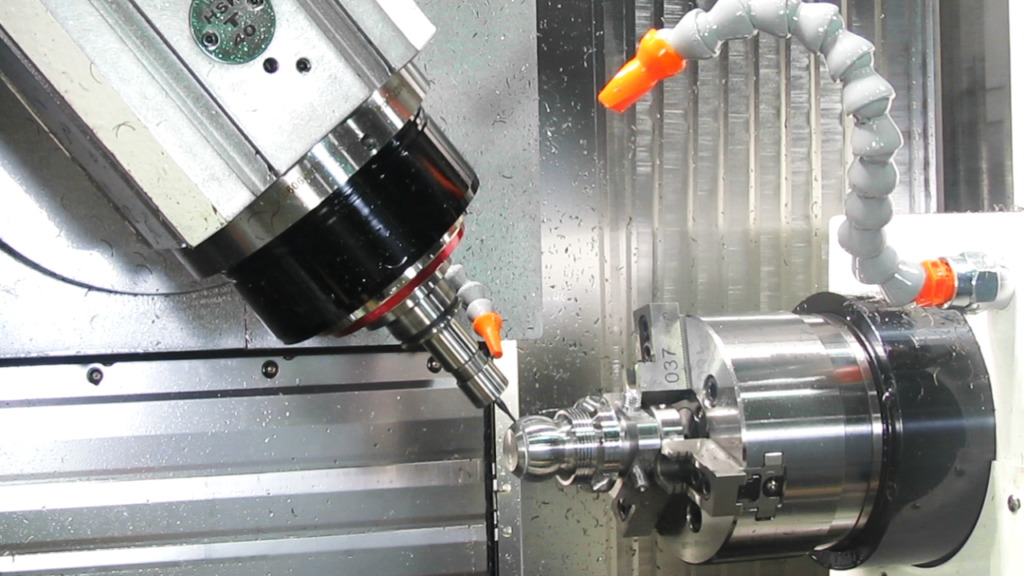

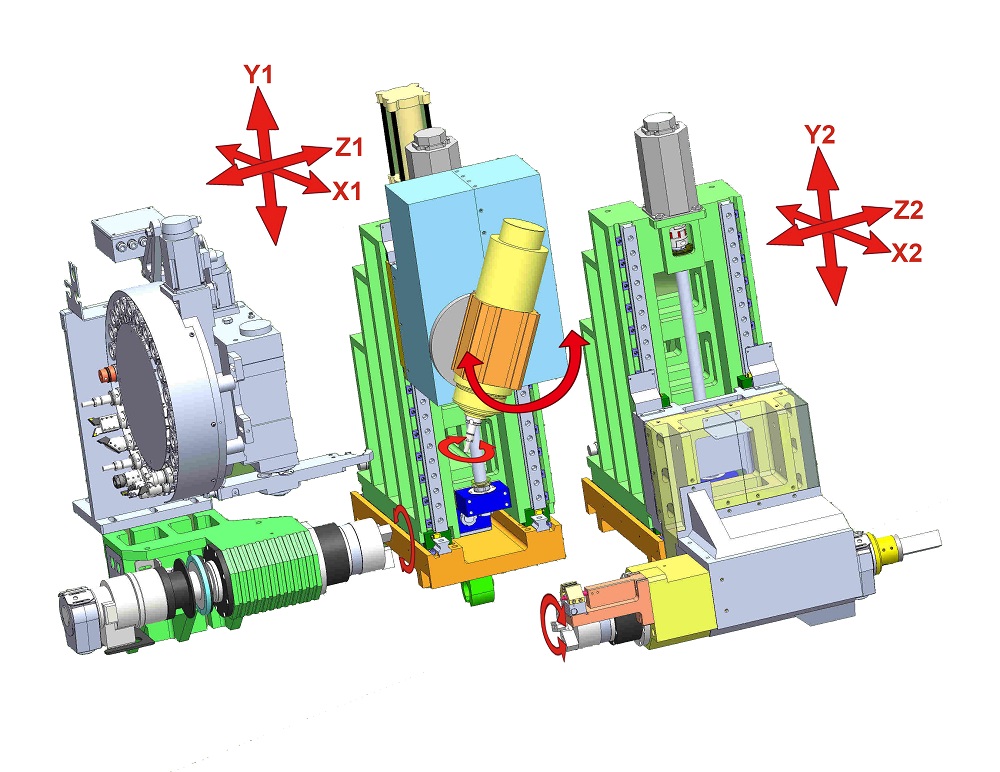

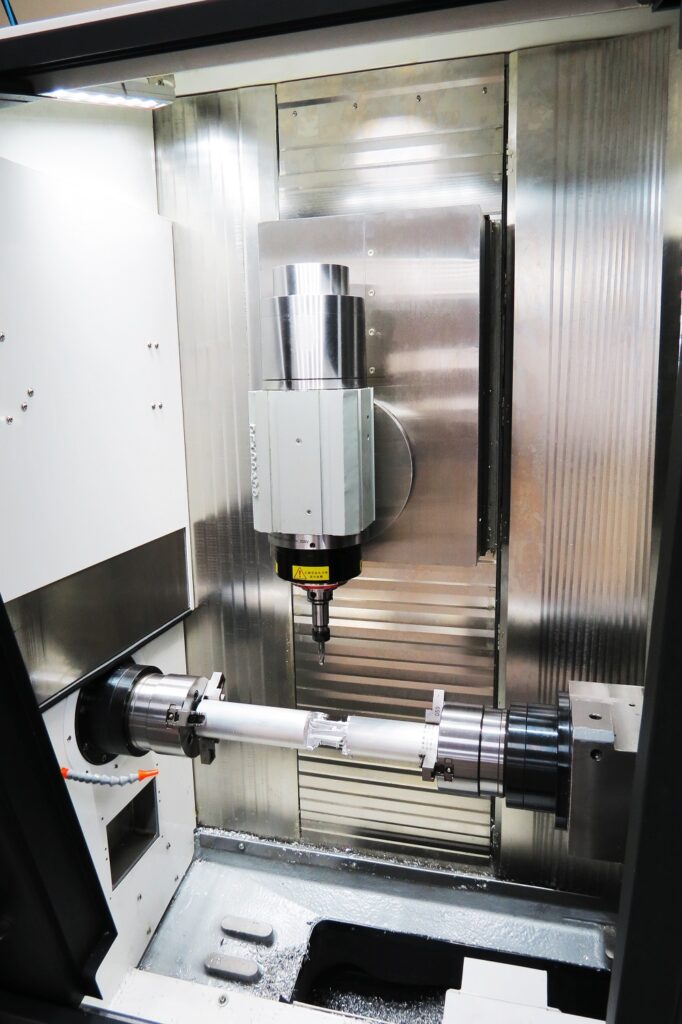

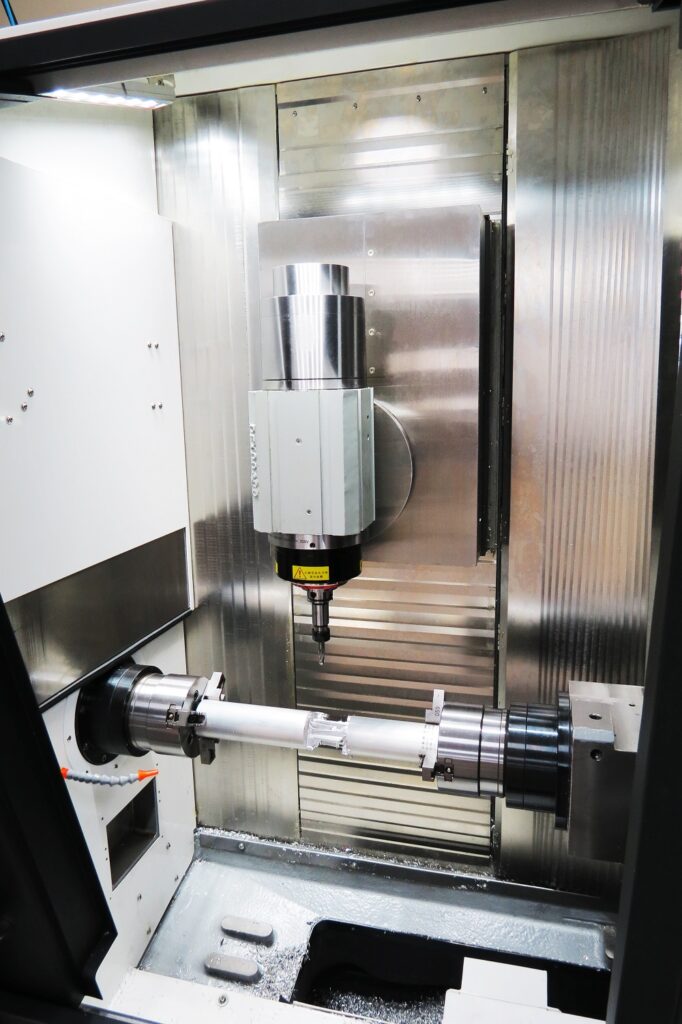

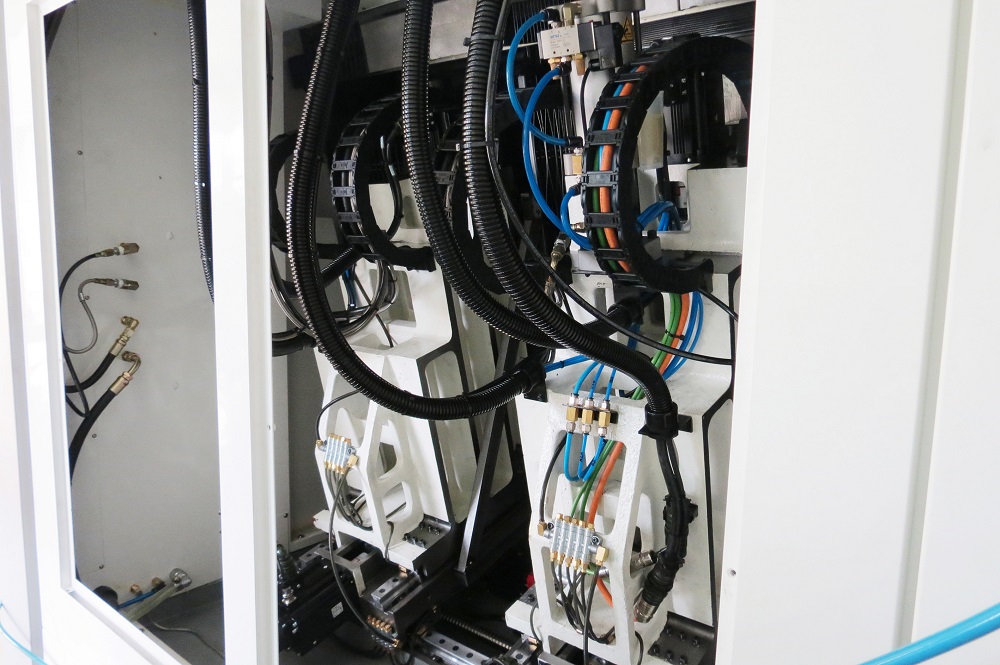

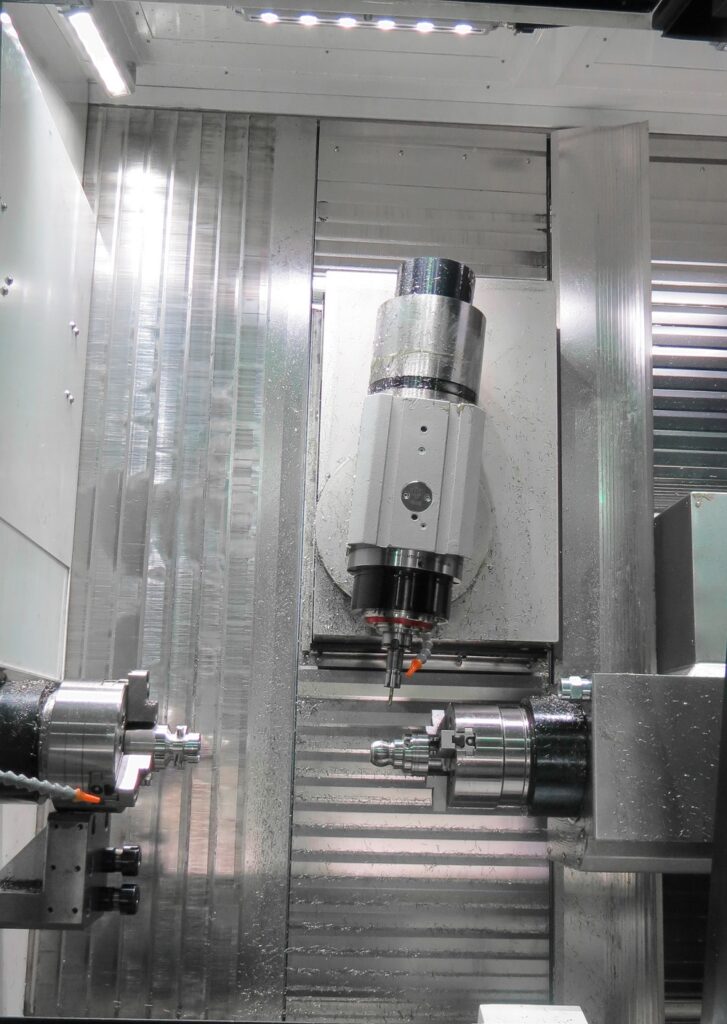

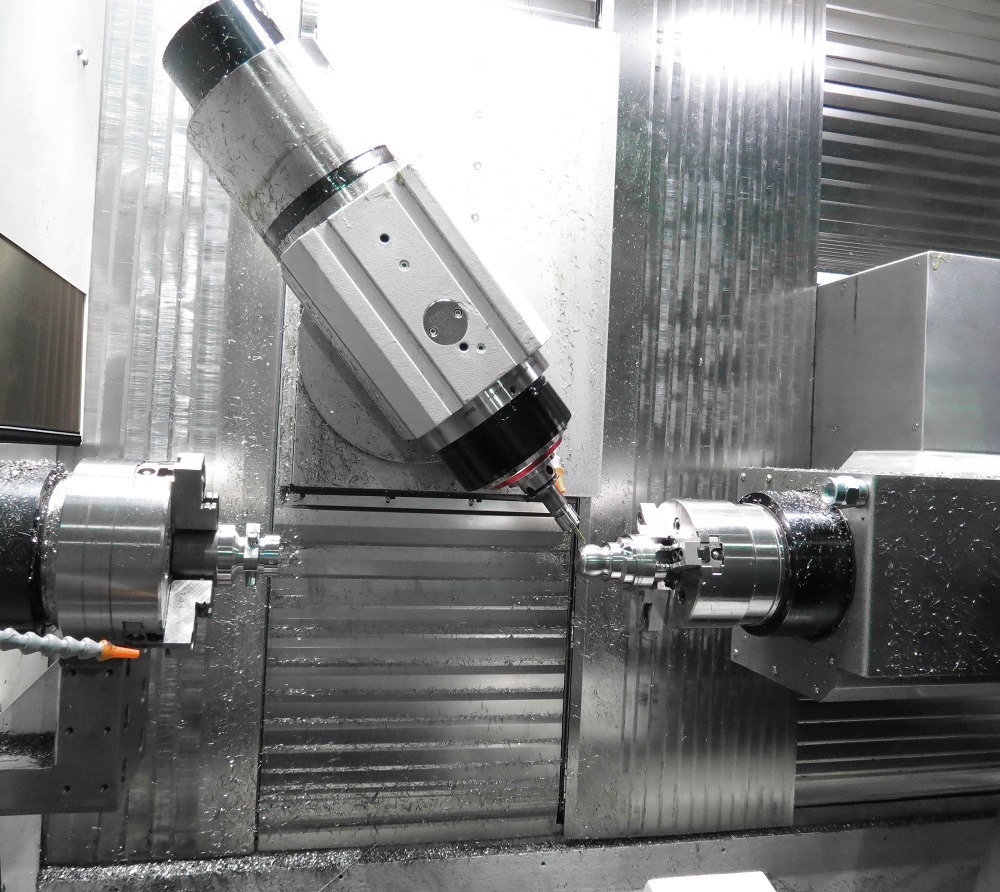

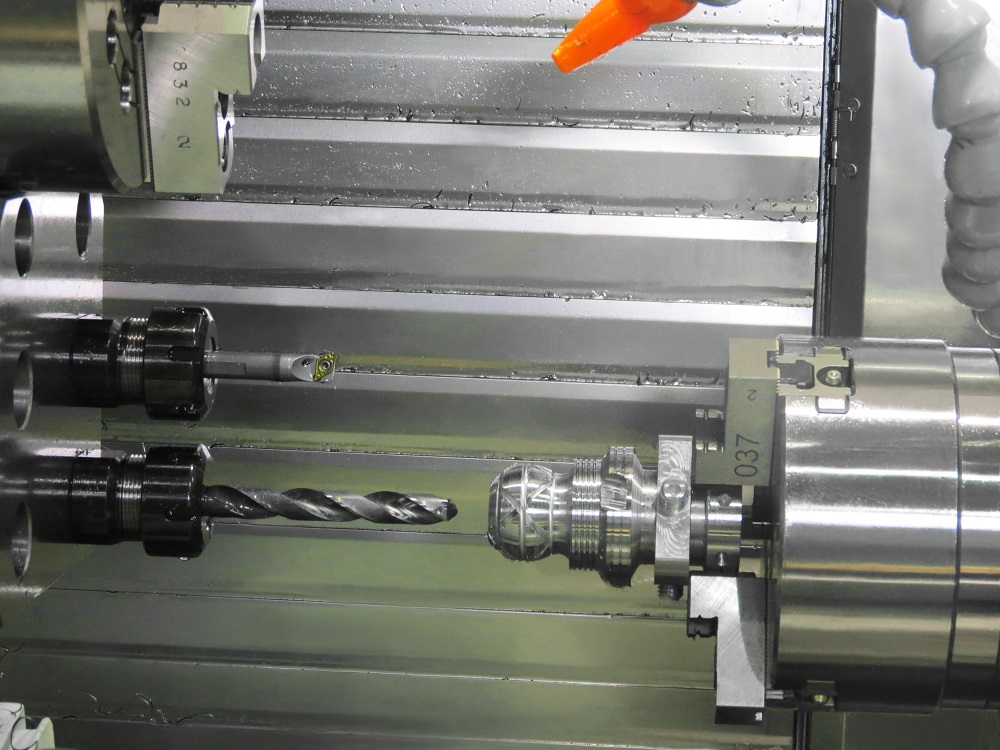

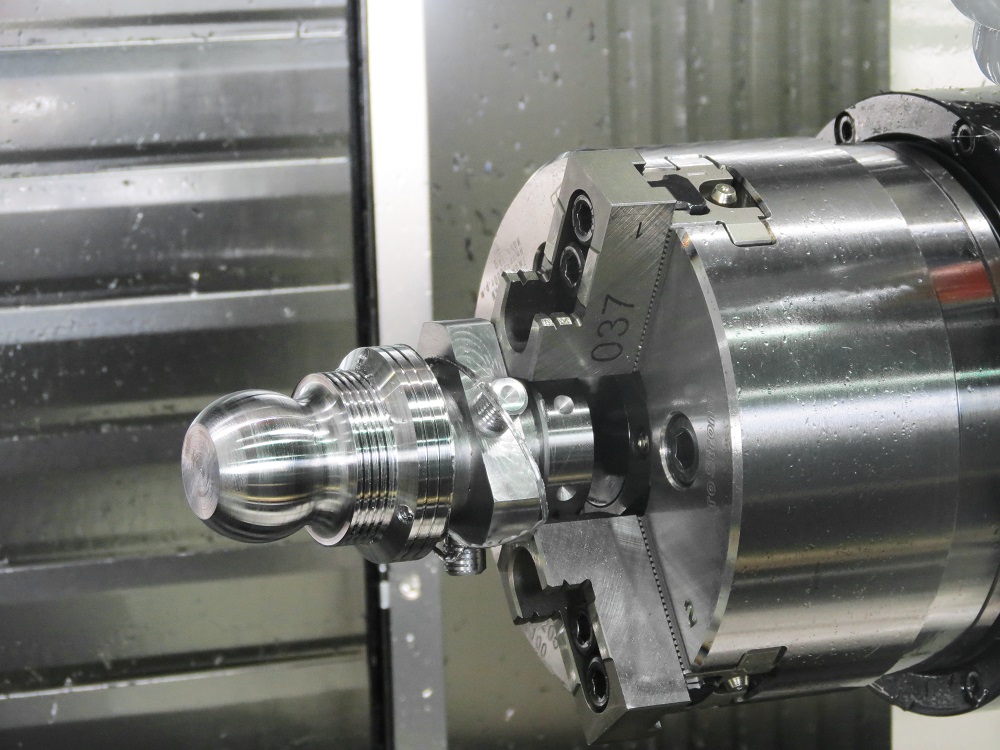

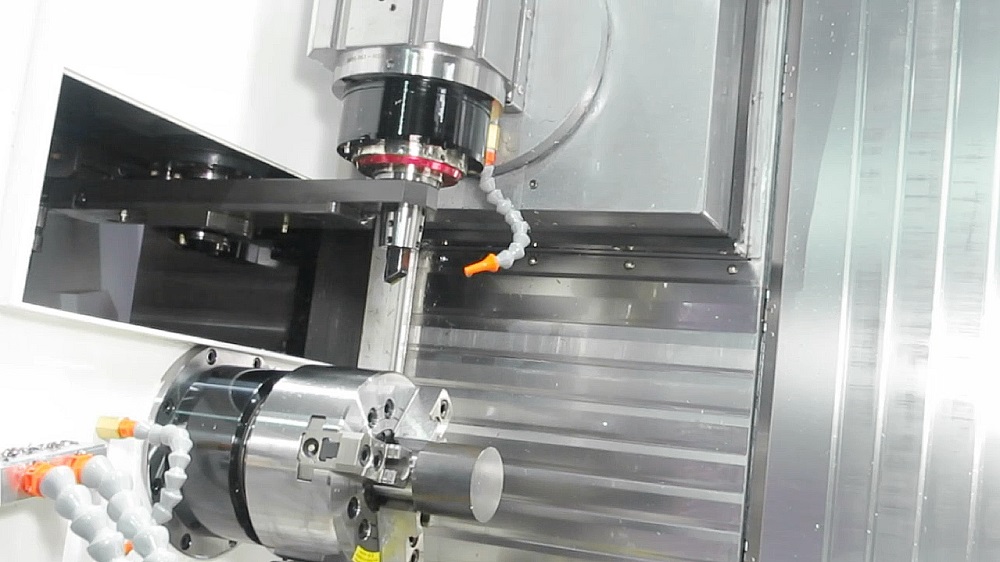

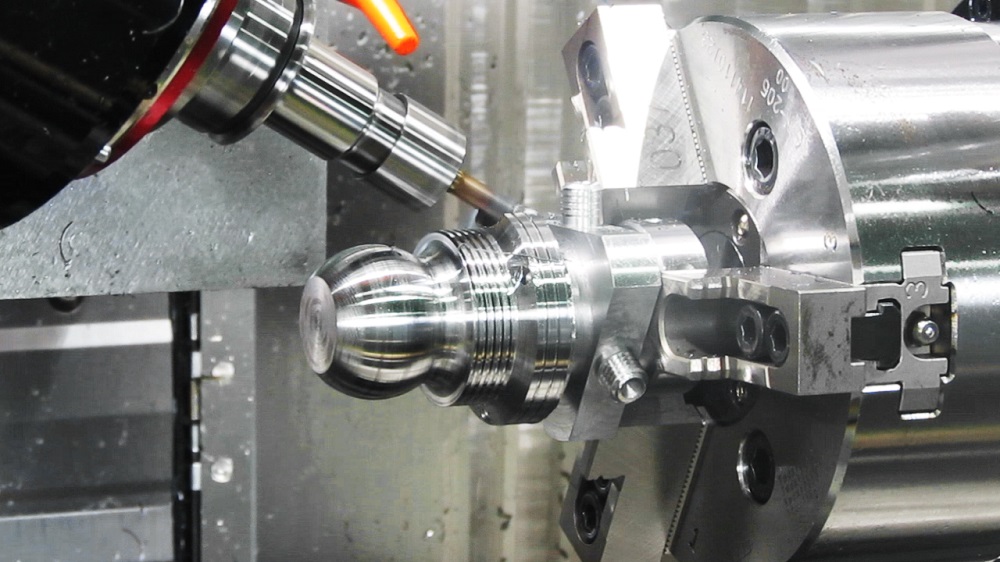

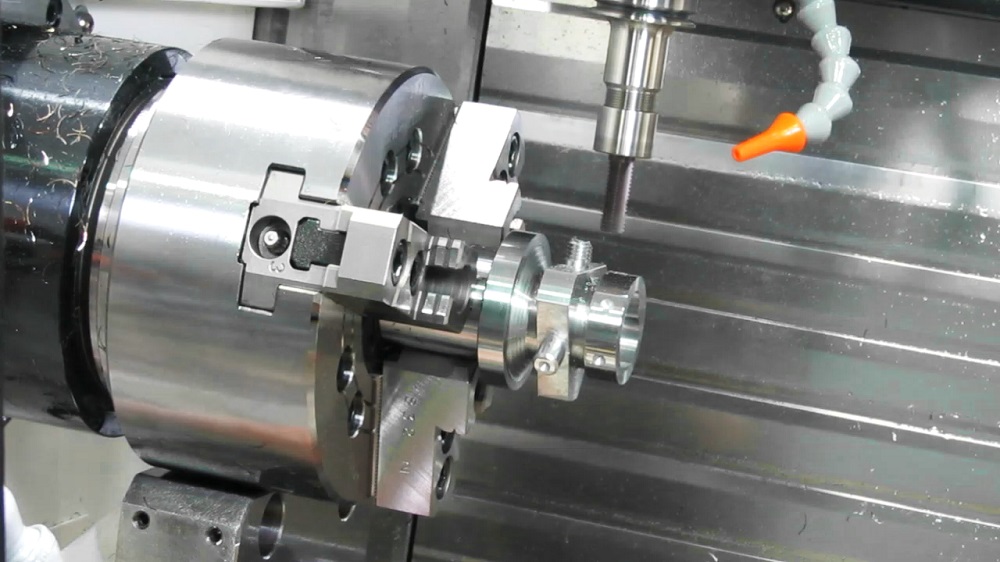

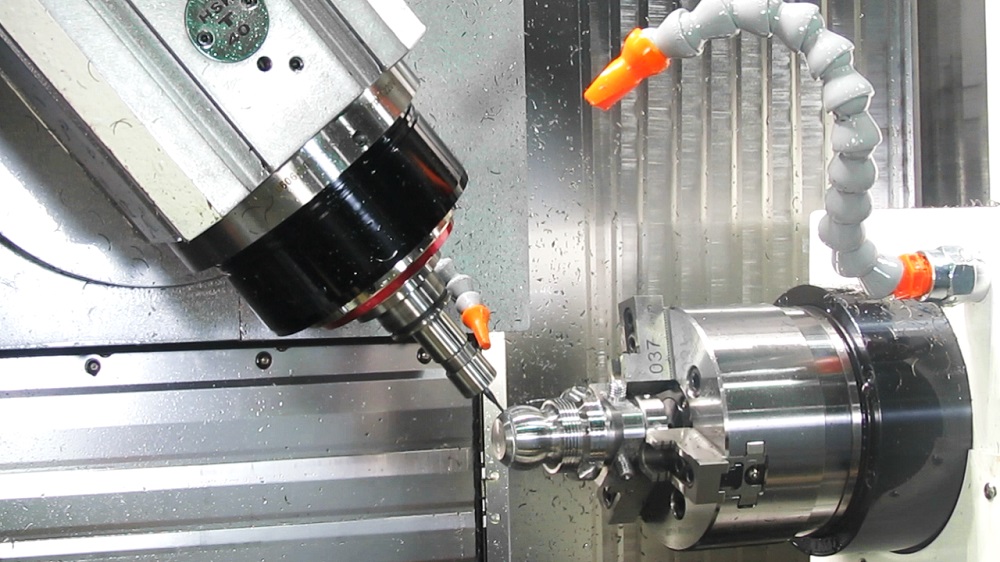

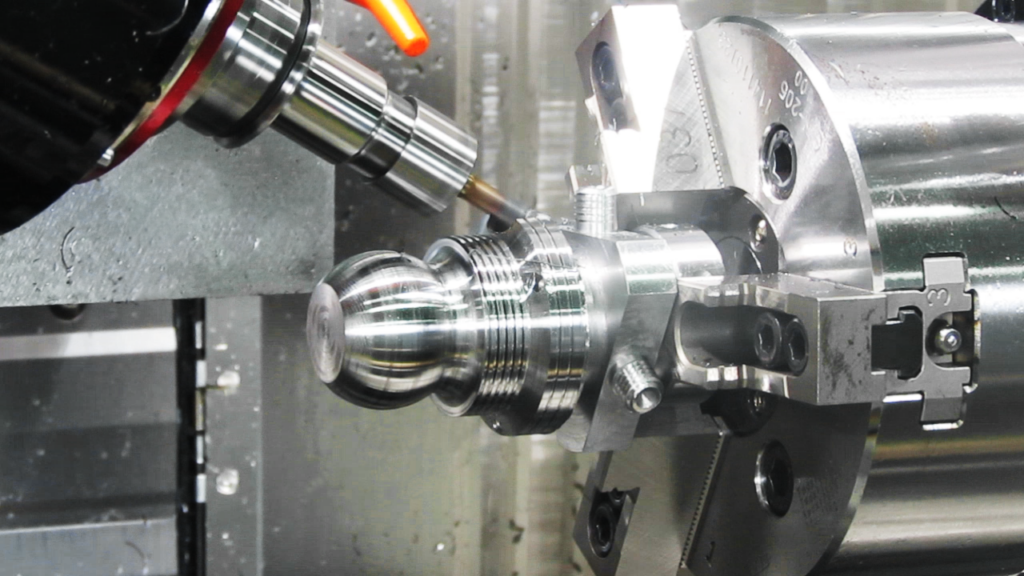

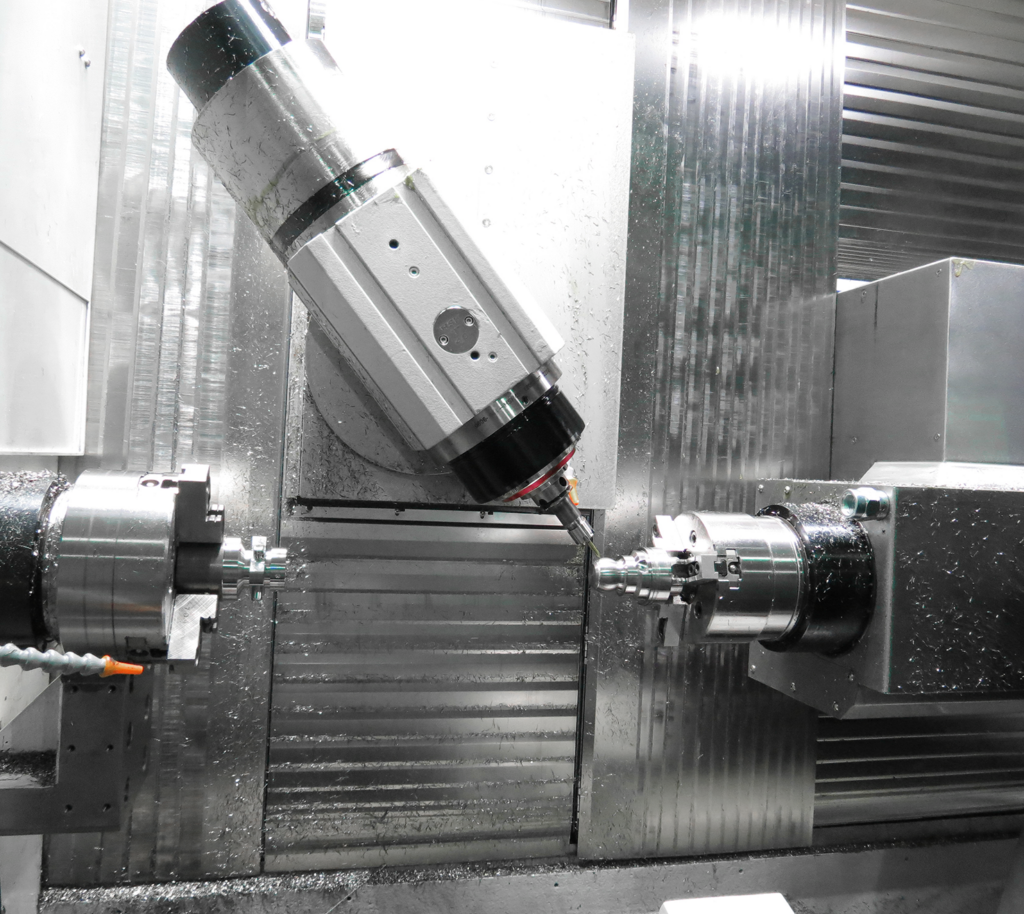

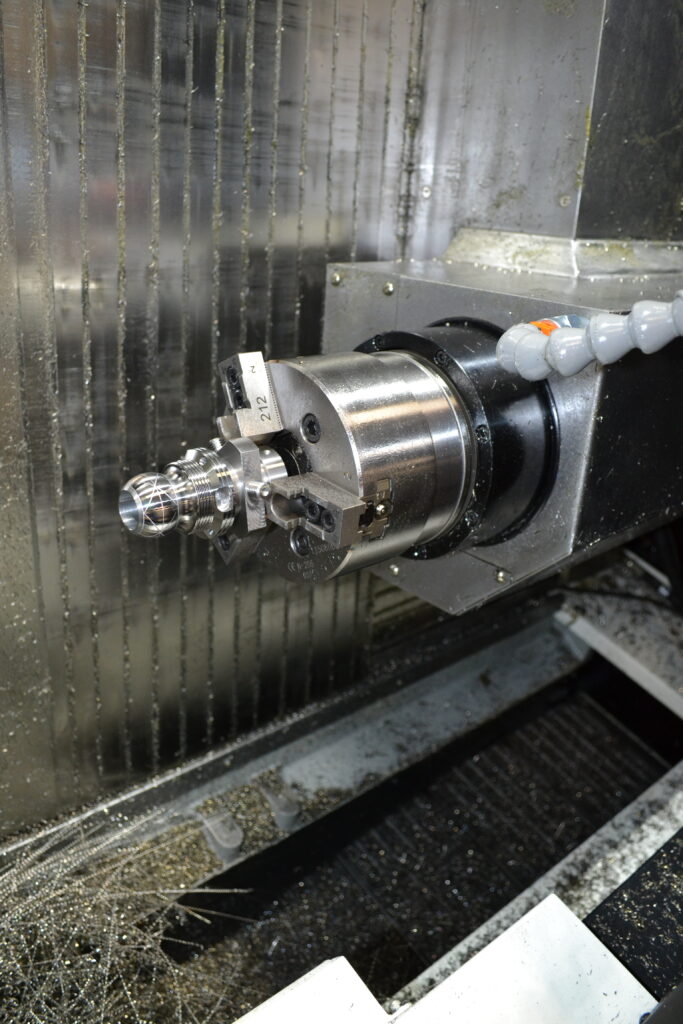

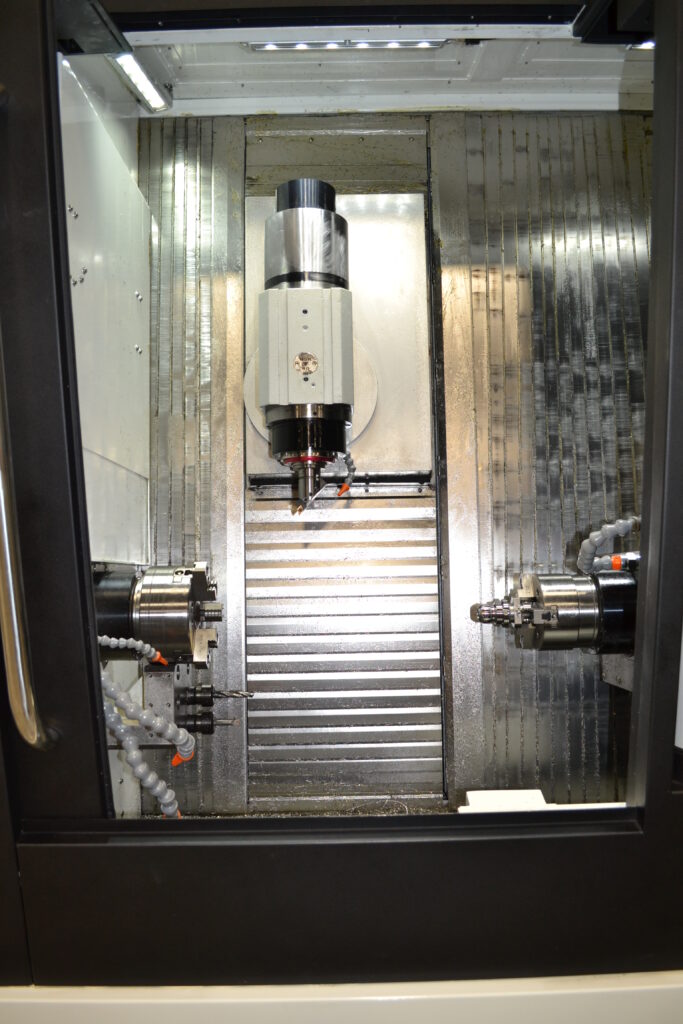

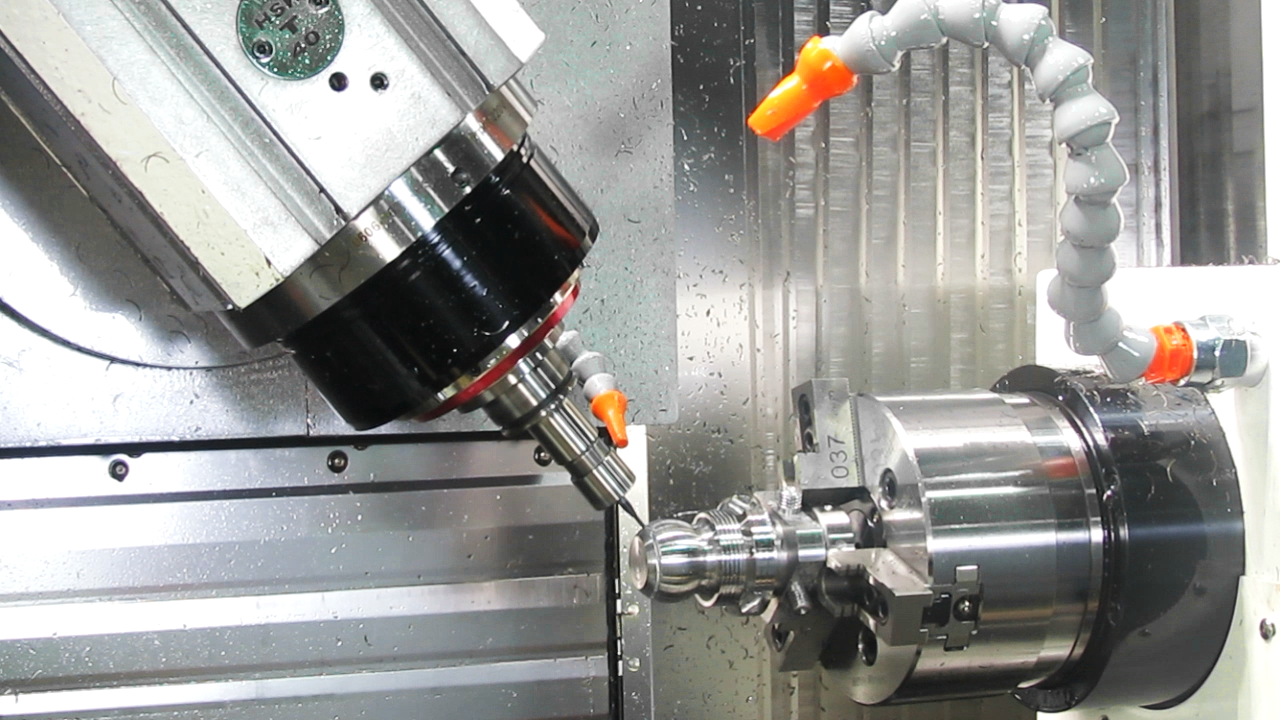

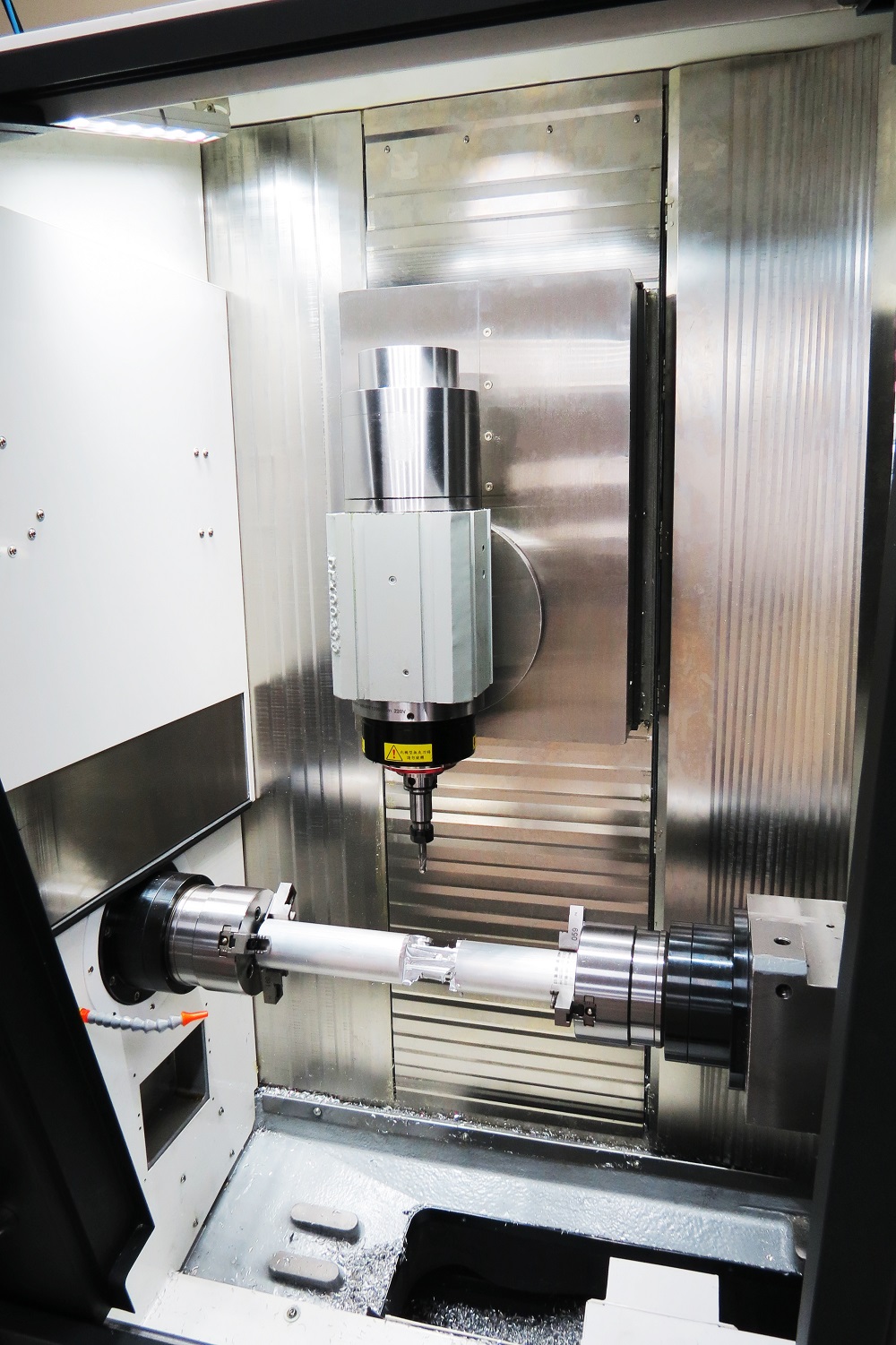

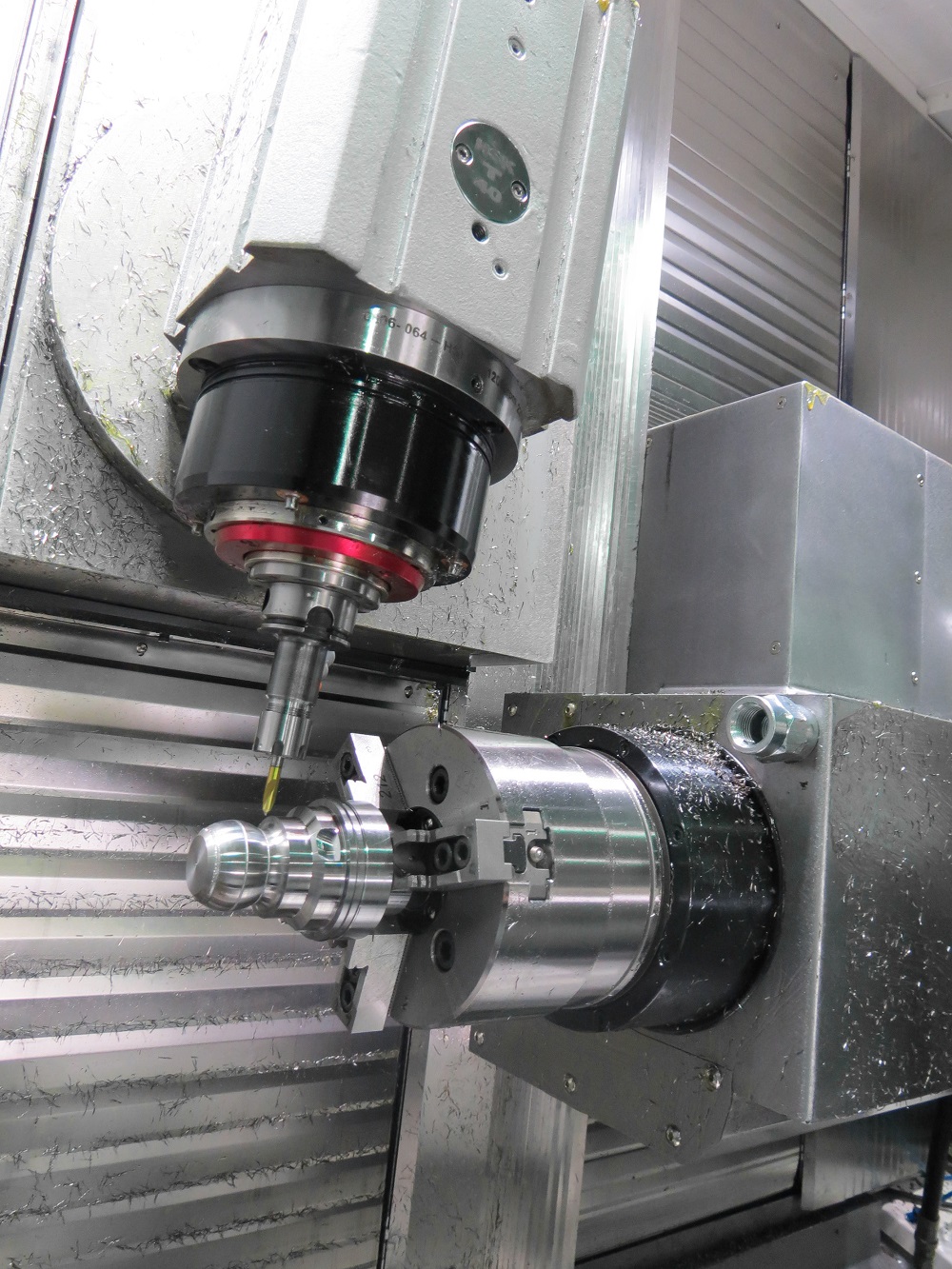

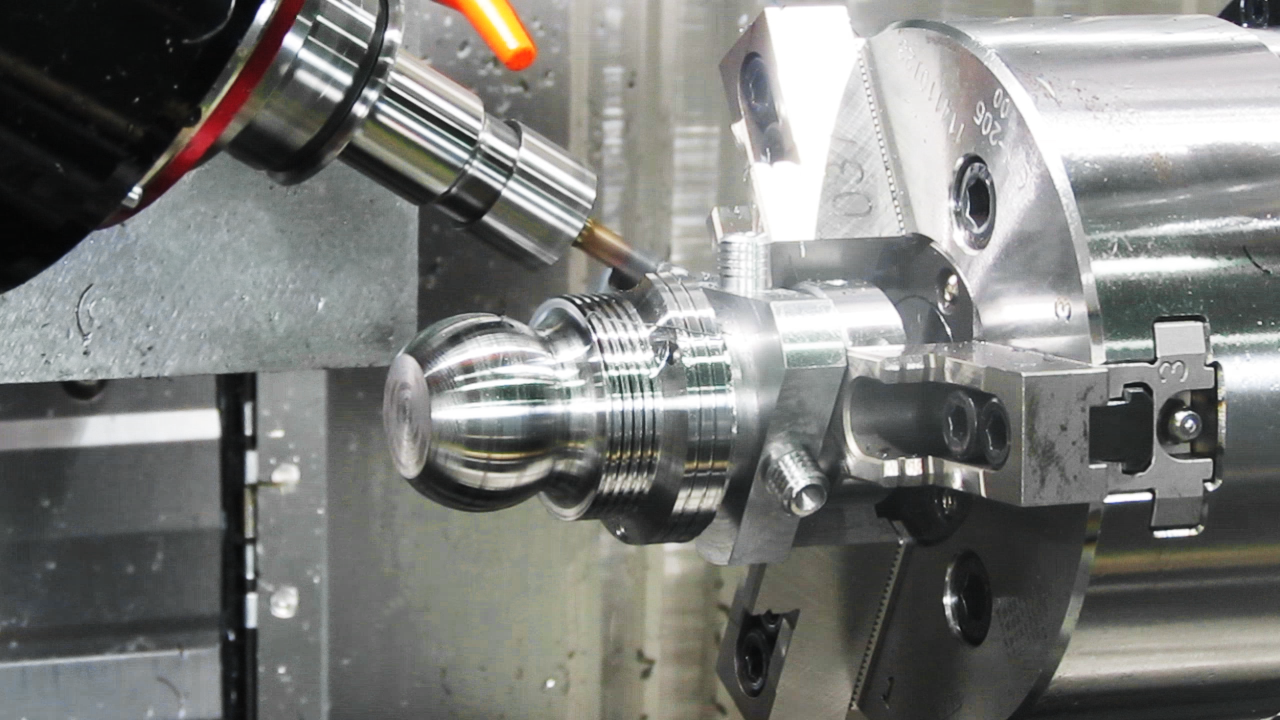

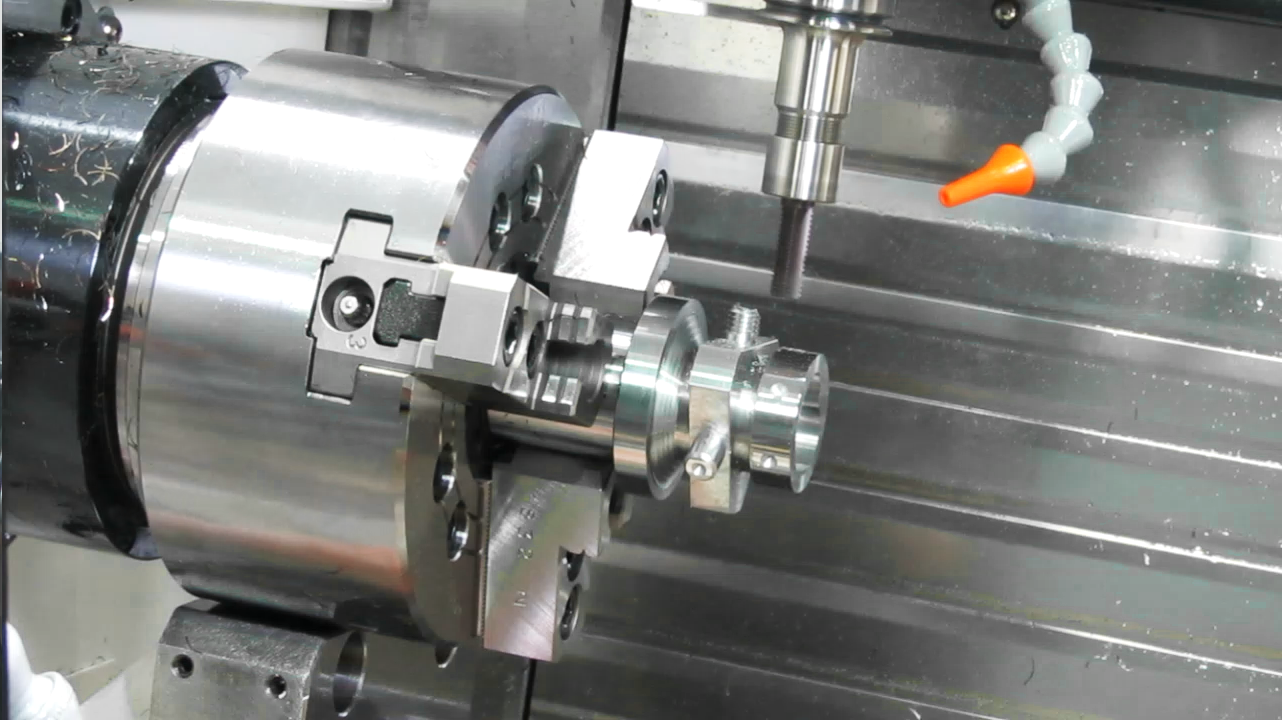

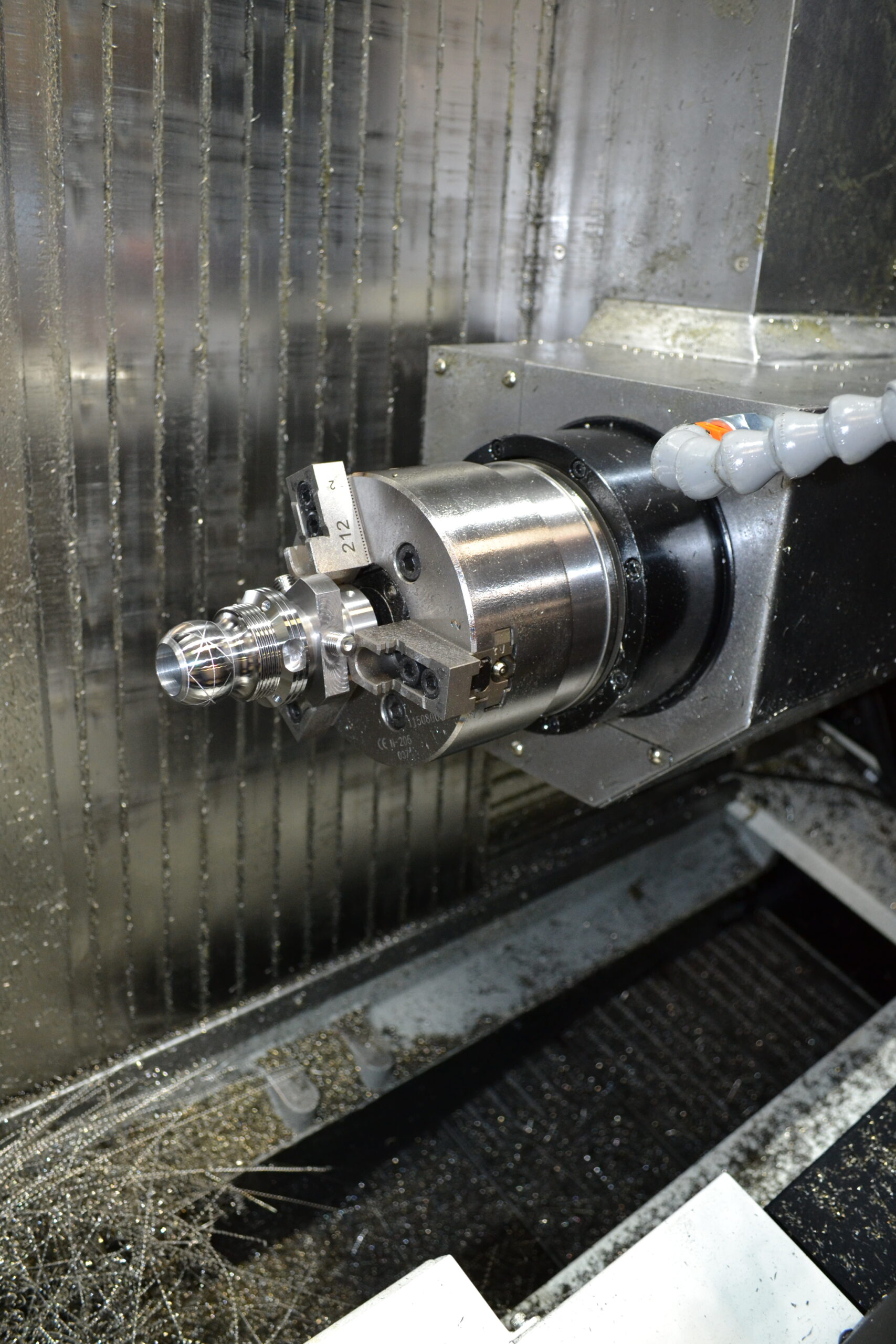

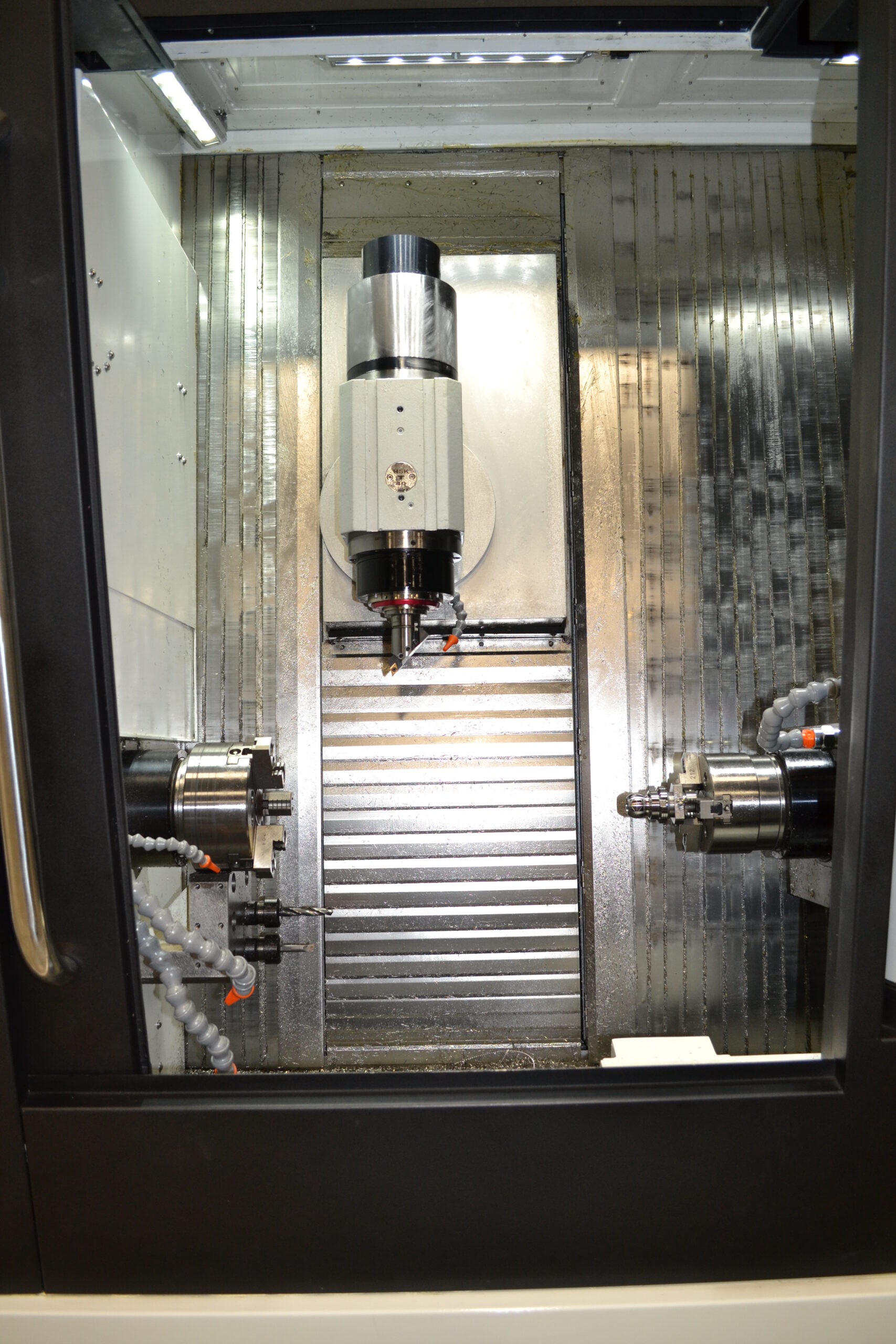

The Quicktech S-ATM Series combines twin turning spindles, a powerful B-axis milling spindle, and 9 total axes of control in an ultra-compact footprint designed for complete machining of small, complex parts. With precision integral-motor spindles and a 24-tool automatic tool changer, these machines perform simultaneous turning, milling, drilling, and tapping on both the main and sub-spindles — all in a single setup.

Ideal for medical, aerospace, electronics, and precision job-shop manufacturers, the S-ATM Series produces tight-tolerance parts with exceptional surface finishes while minimizing handling, cycle time, and floor space. Competitors include Doosan, DMG Mori, Okuma, and Mazak.

Key Features

Specifications

| Item / Model |

S-32 ATM

Request a Quote |

S-42 ATM

Request a Quote |

|---|---|---|

|

Main Spindle Capacity | ||

|

Max Bar Working Capacity |

1.18 (30mm) |

1.65″ (41mm) |

|

Max Turning Length |

15.7″ O.D. / 6.3″ I.D. |

9.8″ |

|

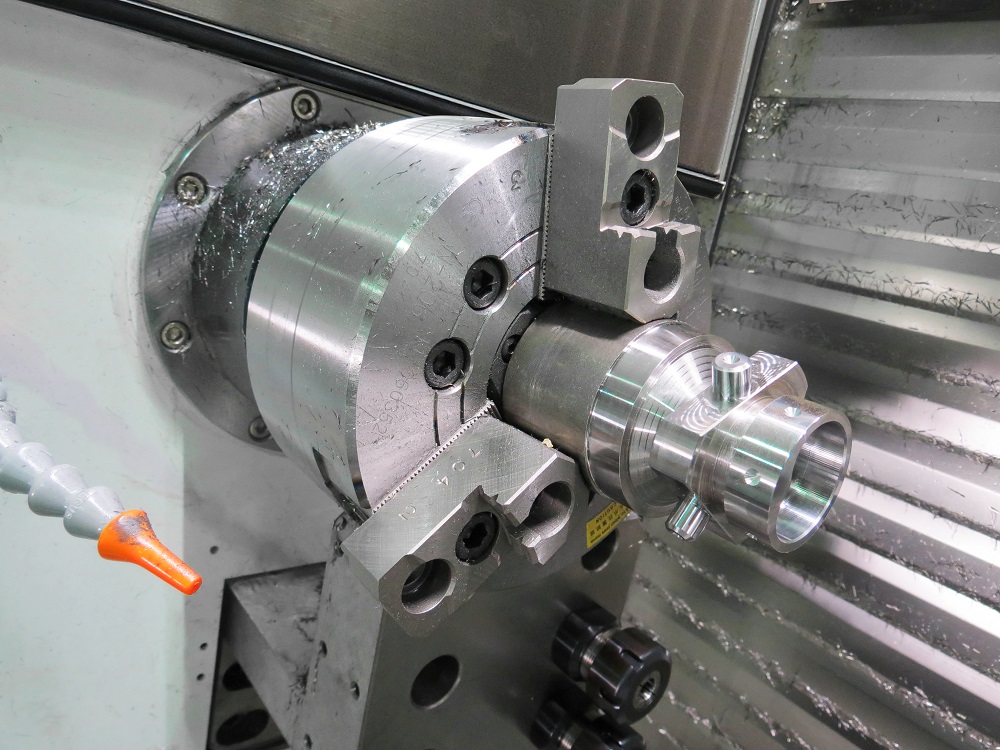

Collet Chuck Size |

5″ 3-Jaw Hydraulic |

6″ 3-Jaw Hydraulic |

|

Spindle Speed Range (std.) |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

5 HP Integral Motor |

15 HP Belt Drive |

|

C-Axis Increment |

.001° |

.001° |

|

Sub-Spindle Capacity | ||

|

Max Bar Working Capacity |

1.18 (30mm) |

1.18 (30mm) |

|

Max Turning Length |

11.8″ O.D. / 2.17″ I.D. |

11.8″ O.D. / 2.17″ I.D. |

|

Collet Chuck Size |

5″ 3-Jaw Hydraulic |

6″ 3-Jaw Hydraulic |

|

Spindle Speed Range (std.) |

6,000 RPM |

6,000 RPM |

|

Spindle Motor |

5 HP |

5 HP |

|

C-Axis Increment |

.001° |

.001° |

|

Milling Spindle and ATC | ||

|

Spindle Speed Range (std.) |

10,000 RPM |

12,000 RPM |

|

Spindle Motor |

3 HP |

13 HP |

|

B-Axis Increment |

.001° |

.001° |

|

Tool System |

HSK-40T |

HSK-40T |

|

Automatic Tool Changer |

24 Tools (36 opt.) |

24 Tools (36 opt.) |

|

Tool Change Time Tool-to-Tool |

1.3 Seconds |

1.3 Seconds |

|

Sub-Spindle Tooling System | ||

|

Tooling Type |

Gang – Fixed |

Gang – Fixed |

|

Number of Tools |

6 |

6 |

|

Tooling System |

ER-20 (ER-25) Collets |

ER-20 (ER-25) Collets |

|

Travel and Feed | ||

|

Rapid Traverse Rate |

1,181″/min. |

1,181″/min. |

|

General | ||

|

CNC Control |

Mitsubishi M830W |

Mitsubishi M830S |

|

Machine Dimensions with Chip Conveyor |

150″ x 87″ x 81″ |

150″ x 87″ x 81″ |

|

Machine Weight |

9,570 lbs. |

9,670 lbs. |