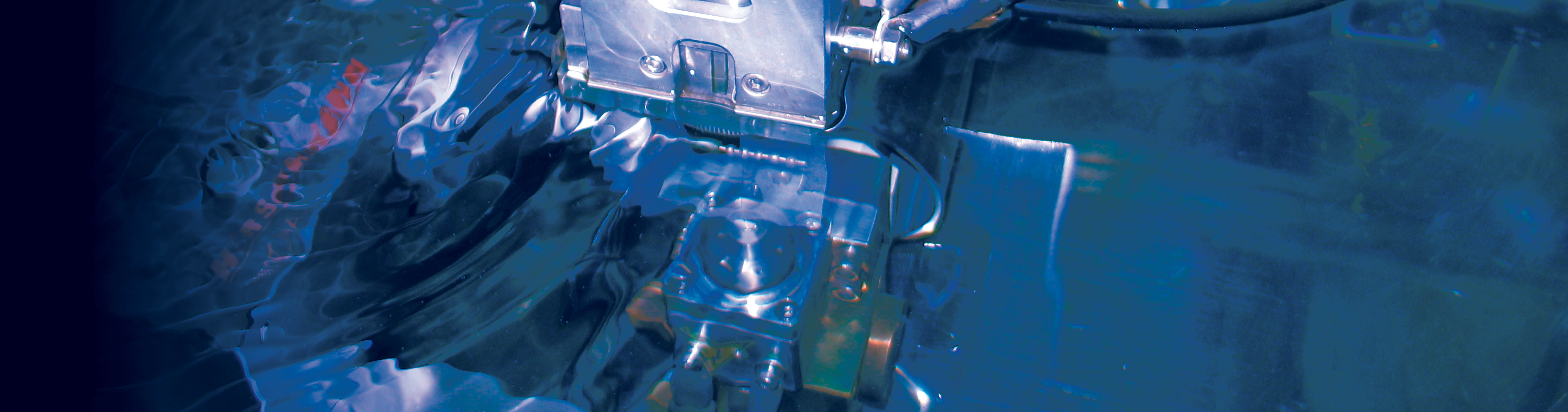

AccuteX Wire EDMs & Die Sinkers

With over 20 years of experience, AccuteX has become a world-class provider of CNC wire EDMs. AccuteX EDM machine tools provide outstanding innovations and competitive pricing, making them a valuable asset for growing your business and your profit.

AccuteX’s unique innovations include:

- Auto Wire Threading at break point

- Under 10 second Spark to Spark

- MST Micro Spark Technology

- 6-axis Turn and Burn

- Stability Discharge Master (1 rough-cut technology)

Hundreds of test cuts have proven that AccuteX outperforms competitors when it comes to speed and finish. Because of its low cost of initial investment and operating and user-friendly in-house developed CNC control, AccuteX EDM machines remain the number one choice for many current AccuteX EDM users. Test Cuts will prove we will outperform our competition when it comes to speed and finish coupled with price.

5 Reasons AccuteX Wire EDMs are Best-In-Class

- Superb Design & Construction: Rigid, heavily ribbed high-grade Meehanite castings. Reinforced water-cooled lower arm is made of high-strength alloy for maximum stiffness.

- Leading Edge Electronics: Electrolysis-free machining. SD master (1 rough cut technology). Superb accuracies and finishes up to RA 0.18um.

- Intelligent Servo-Controlled Wire Threading Technology: Saves time, easy to use threads at wire break point. No need to return to starting point. Under 10 second spark-to-spark time with total reliability.

- Premium Grade Components: Ultra-precise direct-couple drive system-no belts. Fine pitch, ultra-fine-finish ball screws and high-resolution servo motors with 4 millionths resolution. Glass scales.

- User-Friendly Control: Feature-packed control is easy-to-use, versatile and has a large 15″ easy-to-read, full-color touch screen display.